Allied Construction Products, LLC Technical Manual Ho-Pac 300, 300B & 500, 500B

SECTION 9.0

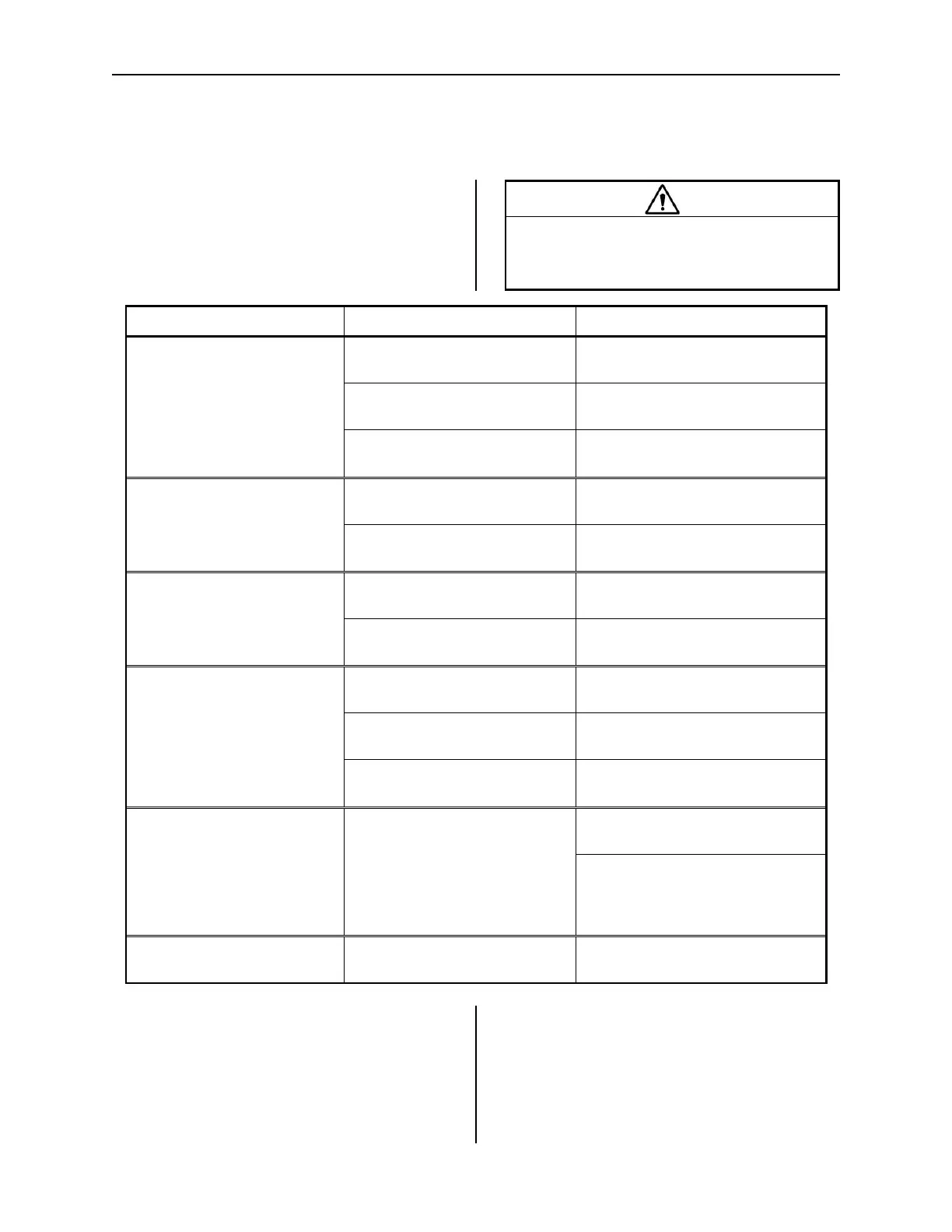

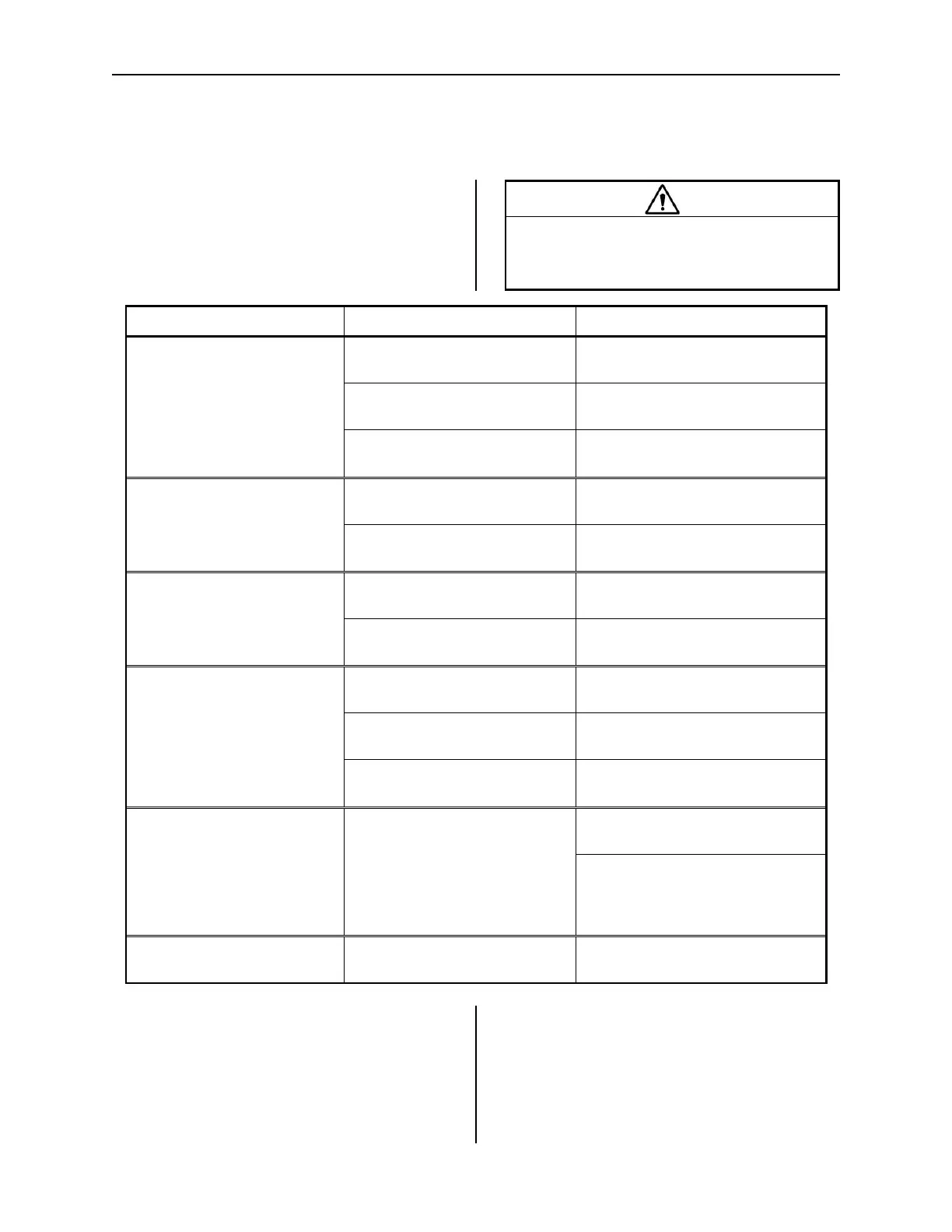

TROUBLESHOOTING

This guide identifies several commonly

encountered conditions and the recommended

course of action. For conditions other than

these, contact the Allied Technical Service

Department.

Only qualified personnel, having

knowledge of the machine’s systems,

proper test equipment and tools should

attempt adjustments and repairs.

Insufficient oil pressure or

flow.

Check hydraulic supply

system. Correct as required.

Inspect and replace bearings.

Broken motor shaft or worn

splines.

Inspect and replace worn

parts.

Erratic oil pressure or flow.

Check hydraulic supply

system. Correct as required.

Inspect and replace failed

mount.

Unit runs with excessive

noise or vibration

Inspect and replace bearings.

Loose bolts or mounting

hardware.

Inspect and tighten bolts.

Unit runs, but stalls

under load

Check hydraulic supply

system. Correct as required.

Inspect and replace bearings.

Motor worn or motor seals

failed.

Inspect and replace motor.

Unit runs smoothly, but

at reduced speed

If motor or flow regulator valve

was replaced, check that the

motor and valve are properly

matched.

Oil discharge from

pressure relief vent

Note: The performance of the attachment is

affected by a hydraulic system that is not

operating to specifications. If the attachment

is not working correctly, make a thorough

check of the carrier’s hydraulic system.

Using a flow meter, measure the oil flow

and determine the cracking pressure of the

relief valve. Include the hoses from the

attachment as part of the test. This will

eliminate the possibility of a collapsed hose.

Compare the results of your test with the

specifications in section 5.1.

Loading...

Loading...