Pro, Solo

INSTRUCTION MANUAL Page 8

SHAW-ALMEX INDUSTRIES LIMITED 49908-042 March 2012

4.4. Basic Assembly and Splice Preparation

Safety: The vulcanizer should be assembled and operated on a flat, level and stable surface so there is no

danger of falling.

1. Lower the pressure bolts and lift top frame from the bottom frame.

2. Prepare the splice as required.

3. Position splice on lower platen. It is good practice to use platen covers between the belt and the top and bottom

platens.

4. Position top frame on the bottom frame, aligning the top and

bottom frame.

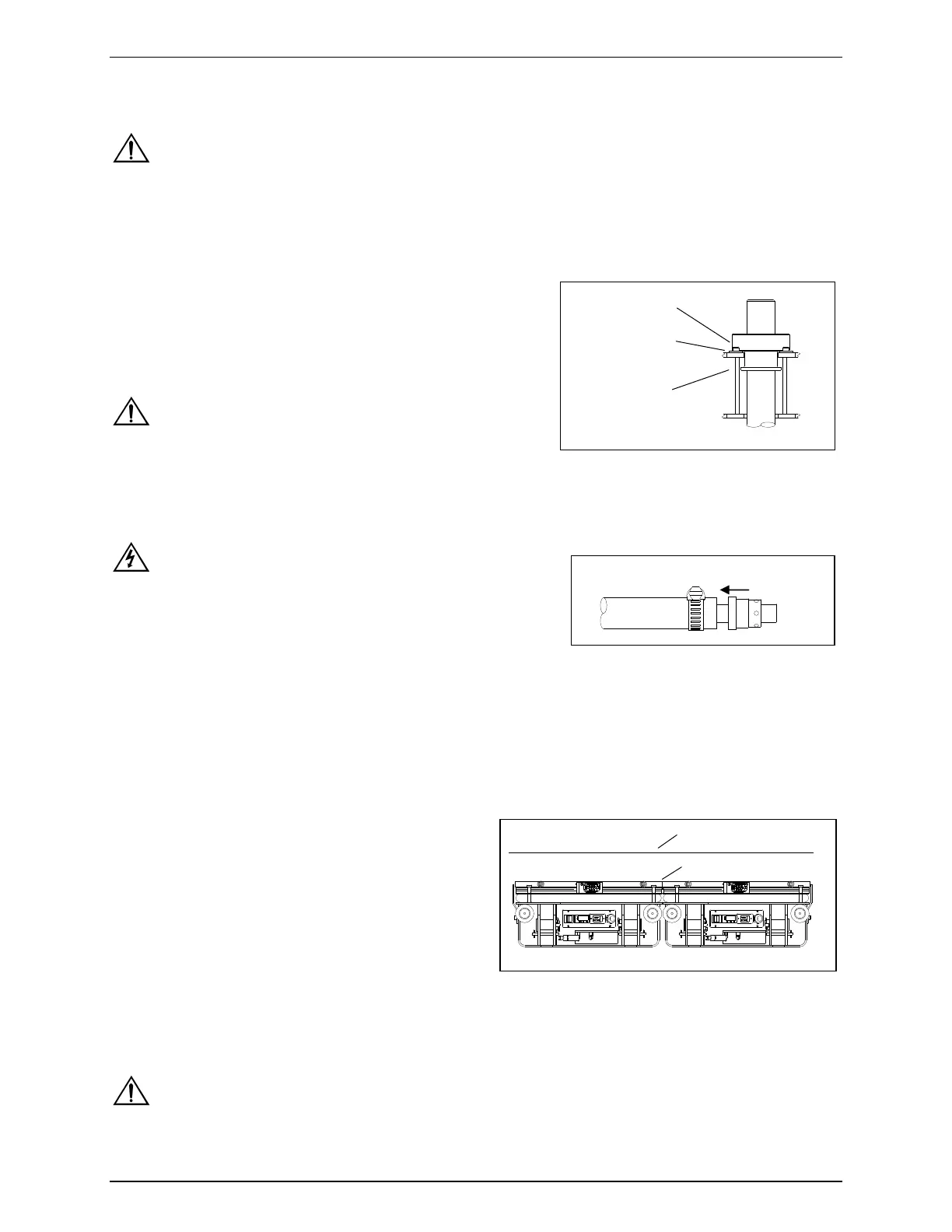

5. Raise the pressure bolts onto the top frame. They will be safely

in position when the top of the nut bears on the bearing cap and

the shoulder is under the edge of the frame, figure 2.

Safety: Failure to engage the pressure bolt properly could

result in over stroke damage to the vulcanizer and injury when

pressure is applied.

6. When using frame mounted temperature controls, connect the

panels to two separate power supply circuits. The temperature controller will illuminate, but the platen will not

start heating until the switch is on (1A-on, automatic or 1M- on, manual). See temperature control manual.

Safety: Each platen may have to be connected to a separate

circuit to avoid exceeding the current carrying capacity of the power

supply.

7. When using remote temperature controls, connect the top and

bottom platen electrical cables to the platen connectors and

connect the panel to a power supply. The temperature controller

will illuminate, but the platen will not start heating until the switch is turned to 1A (on, automatic) or 1M (on,

manual). See temperature control manual.

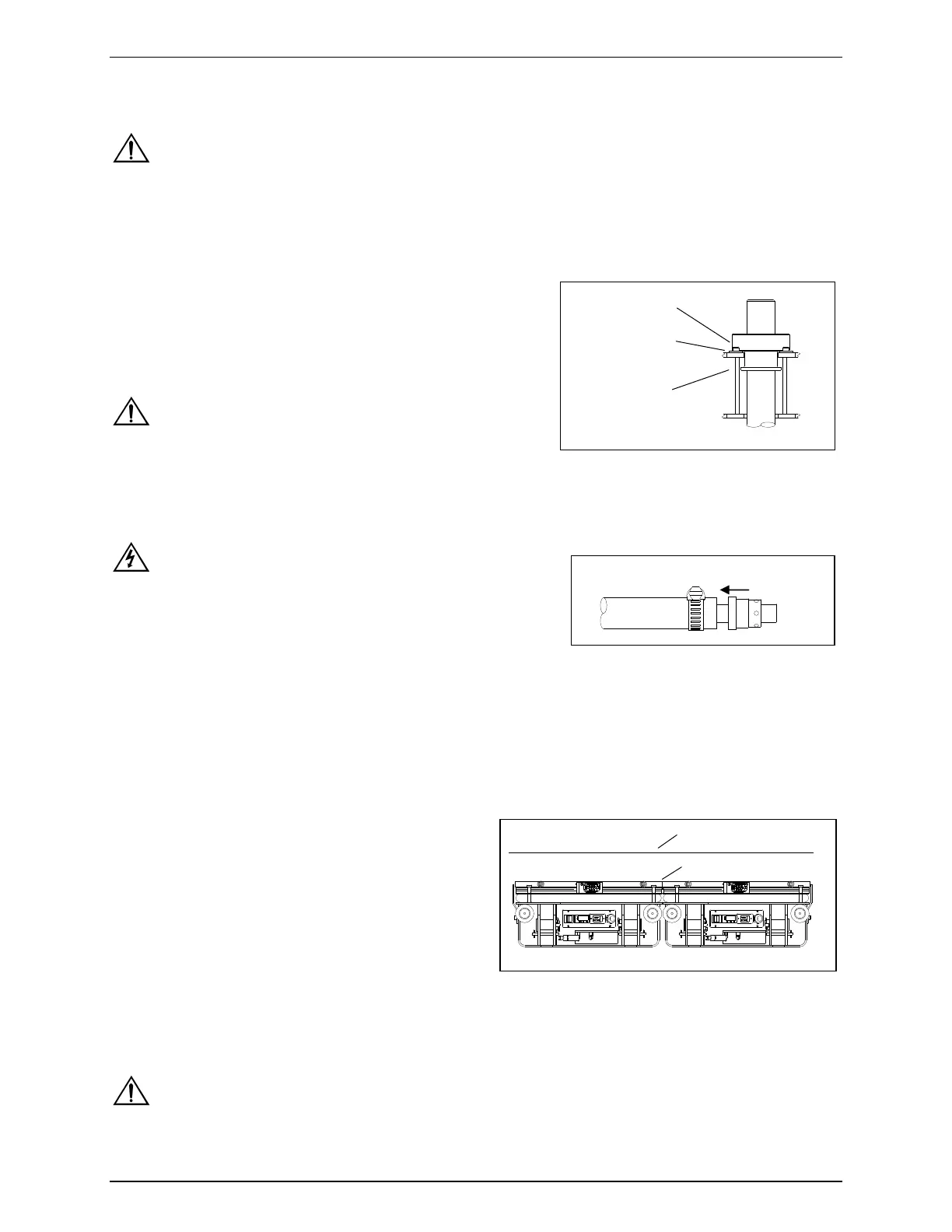

8. Connect the top and bottom platen cooling supply and drain hoses. To disconnect the hoses, pull back on the

collar on the quick connect plug.

4.5. Assembling Presses Side by Side on a Splice

All Pro and Solo presses can be positioned side by side

with their platens touching in order to make a larger platen

area.

1. Remove the platen guard from the side(s) of the presses

to be used together by loosening the platen guard

assembly bolts.

2. Remove the platen covers by removing the screws from

the side of the platens.

3. Cover the top and bottom platen area with a 1/8" thick

(3 mm) metal cover plate (aluminum, steel or stainless

steel).

4.6. Changing Handle Position

The handles can be located on the sides or the end of the frame. Tighten by hand only.

Safety: When changing the handle position, be sure the handles are threaded all the way in.

Top of Nut

Bearing Cap

Shoulder of Nut

Figure 4

Figure 2

Cover Plate

Platens touching

Pull to release

Loading...

Loading...