Pro, Solo

INSTRUCTION MANUAL Page 9

SHAW-ALMEX INDUSTRIES LIMITED 49908-042 March 2012

5. OPERATION

There are two essential requirements for perfect splicing of conveyor belting; Uniform Pressure and a controlled

Uniform Temperature. Both of these requirements are satisfied in the ALMEX Vulcanizer.

Uniform Pressure:

Full platen size pressure ‘bag’ applies uniform pressure over the entire platen area.

Important: This unique platen requires support over its entire area or permanent distortion of the platen may occur.

Fill any unused portion of the platen area with material the same thickness as the belt.

Uniform Temperature:

The heating element is a silicone rubber ‘blanket’ which covers the total platen surface.

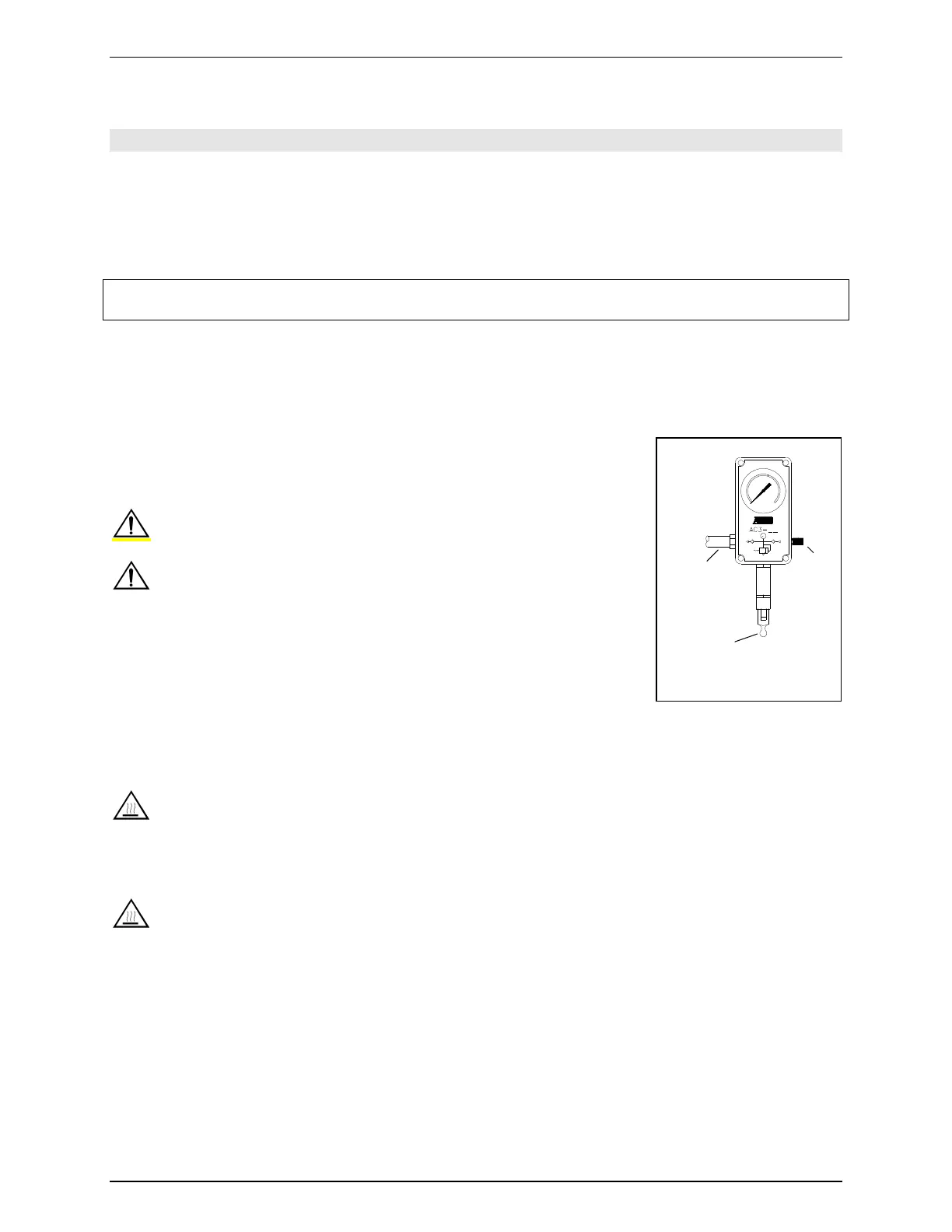

5.1. Pressurizing with Air

The air control on Pro models is attached to the frame with an industrial type of

fastening pad. Remove the air control from the frame and pull out sufficient hose to

pressurize away from the end of the frame. The air control on Solo models is

separate and must be connected to the fitting on the bottom frame.

Safety: Do not lean against the vulcanizer when pressurizing. Component

failure can result in a sudden movement of the frame and could cause injury.

Safety: The Air Release/Pressure Relief valve is preset to blow off slightly

above operating pressure. Do not override this safety device or injury could result.

1. Turn the safety relief valve toggle so it is at a right angle with the valve.

2. Apply air (using compressed air or a hand / foot pump) until the desired air

pressure is reached as indicated on the gauge. Make sure air is actually entering

the pressure bag before commencing to heat the platens.

3. To de-pressurize, turn the toggle on the pressure relief valve so it is in line with

the body of the valve.

5.2. Heating the Vulcanizer

Safety: Never heat the vulcanizer while unattended.

1. Adjust the set point value of the temperature controller. If not familiar with the temperature controller, refer to

the manual supplied with the temperature controller for instruction.

2. Turn the switches on the temperature controller to the on position (1A-on, automatic or 1M- on, manual).

Safety: The platens will get hot.

3. Heat to set point temperature and then time the cure according to the belt manufacturer’s specification. Monitor

the platen temperature with the stem thermometers as well as the controller display.

Note: There are holes on the end of the platen opposite the electrical connector for inserting a stem thermometer. It

is good practice to verify the platen temperature with stem thermometers.

Tip: The use of different platen cover plates will affect the heat up time and may cause a difference between the

controller temperature reading and the actual temperature of the product. Cure temperatures and times may have

to be adjusted to compensate for this difference.

4. When the cure is finished, turn the switches on the temperature controller to the off position (0).

Figure 5

Air

In

Bag

Hose

Safety Relief

Valve Toggle

Loading...

Loading...