SVP INSTRUCTION MANUAL Page 15

SHAW-ALMEX INDUSTRIES LIMITED 49909-010

Jun 2017

3. The cooling water can be turned off when the platens have cooled to an acceptable temperature. A typical

cool down temperature is 150F (65C) for a good splice result and safe handling of the belt without the

risk of a burn.

4. The water must be blown out with air before the platens are reheated.

Important: Water remaining in the cooling channels will reduce platen temperature uniformity, increase the

heat-up time and may cause the elements to overheat. Furthermore, if water remains in the platens and the

vulcanizer is stored at temperatures below freezing the platens may be severely damaged.

5.4. Depressurize

1. To de-pressurize the vulcanizer, slowly open the pressure release valve on the pressure control.

2. When the pressure has dropped to zero and the fluid has stopped flowing, the pressure supply can be

disconnected.

Safety: Do not attempt to disassemble the press until the pressure has been completely relieved or injury

could result.

6. MAINTENANCE

Safety: All maintenance must be done with the vulcanizer disconnected from the power supply and no

pressure in the bag.

There are no special tools required to maintain this equipment.

6.1. Routine Maintenance

The following items should be checked after every thirty cures.

1. Visually inspect the traverse bars, tie bolts and pins for signs of cracking or deformation. Some dry

lubricant can be applied to the bolt threads.

2. The threads on pressure bolts should be inspected using die penetrant after each 200 cycles.

3. Inspect the bolt retaining lugs at the ends of the bars to ensure that there are no cracks. Remove the bars

from service if there are cracks and contact Shaw-Almex.

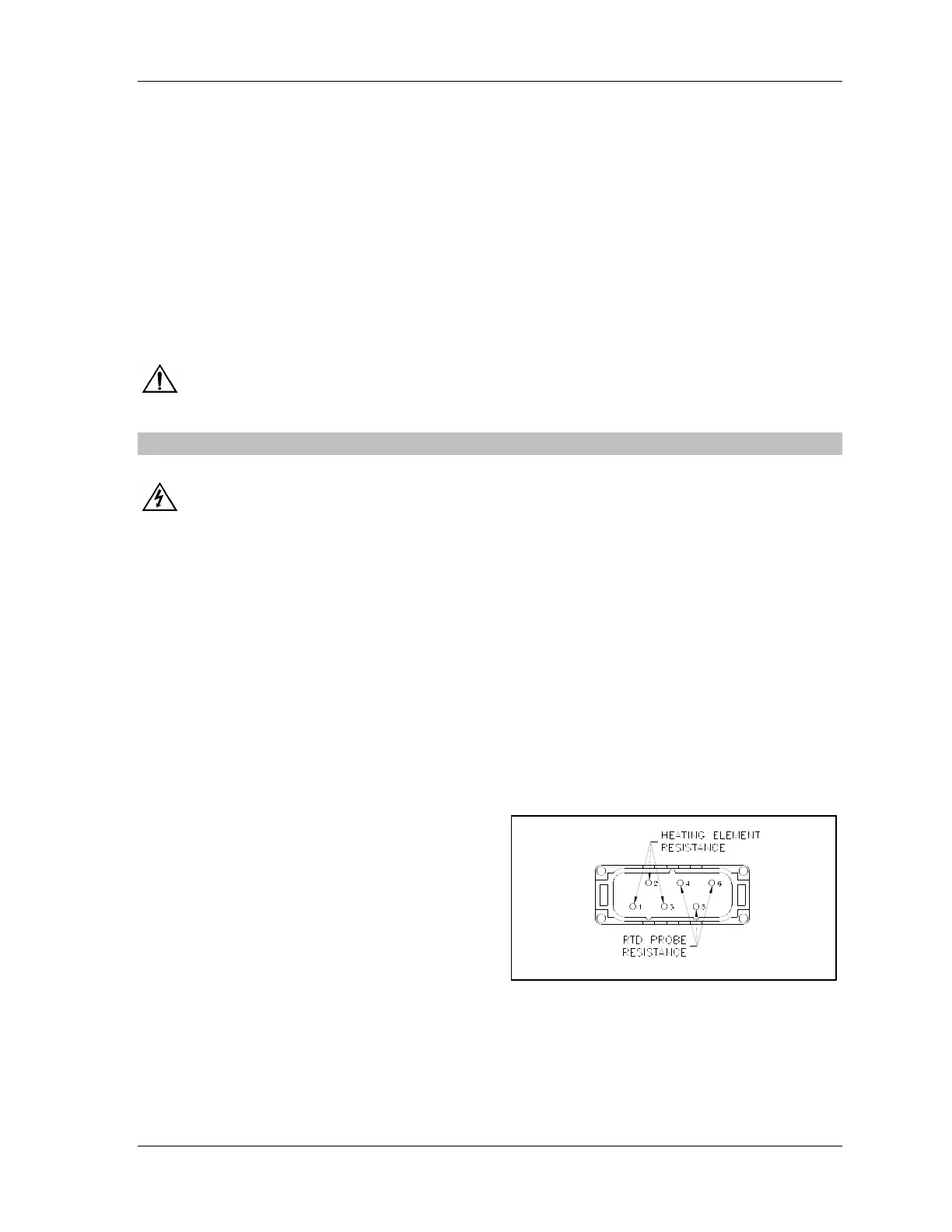

4. Check the continuity of the platen heating elements. Refer to “Record of Purchase” for the resistance

(ohms) values. Use the figures from the “Ohms Reading Coils Connected” column. This is the resistance

between pins 1-2, 2-3 and 1-3 on the platen connector.

5. Check the continuity of the platen temperature

sensor. See 7.1 Platens Not Heating item 3

6. Inspect the platen pressure bag, hoses and

connectors for damage due to abrasion, cuts or any

type of damage that might cause a leak or

breakdown while under pressure.

7. Inspect all cables for cuts, abrasion and wear and all

“strain relief” fittings between cable and plugs for a

secure fit. If any cable, hose, fitting or pressure bag

shows signs of damage they should be repaired or

replaced.

8. Inspect the platen cooling for leaks and/or blockages that will affect their performance.

9. The platen insulation should be inspected for damage and for compression. Compression of the insulation

will cause the platen assembly screws to protrude above the insulation. If the screws cannot be tightened,

the insulation should be replaced.

Tip: Assembly bolt threads on Almex vulcanizers are coated with an anti seize compound to facilitate removal

and replacement of components in service. This compound will be worn off when assembly bolts are removed

Loading...

Loading...