SVP INSTRUCTION MANUAL Page 11

SHAW-ALMEX INDUSTRIES LIMITED 49909-010

Jun 2017

18. Install the restraining bars. With the gauge pin

removed from one end, slide the bar through each

traverse bar and install the gauge pin. Both gauge

pins should be approximately 3/4” (18 mm) from

the side of the outer traverse bars.

19. Install the bolt retaining pins through the holes in

the remaining upper and lower bars.

Safety: The restraining bars, gauge pins, and

bolt retaining pins are safety components. When used

together this feature will protect against hazards that

might result in the event of a bolt failure.

20. Adjust the edge irons.

21. Position the temperature controls and pressure

controls at the splice location.

22. Make electrical, pressure and cooling connections as shown on the General Arrangement drawing at the

back of this manual. If unfamiliar with this procedure, refer to the manuals for the temperature controller

and the pressure controller.

23. Connect the top and bottom platen electrical cables to the temperature controller and connect controller to

power supply. See temperature controller manual.

24. Connect the top and bottom platen cooling supply and drain hoses.

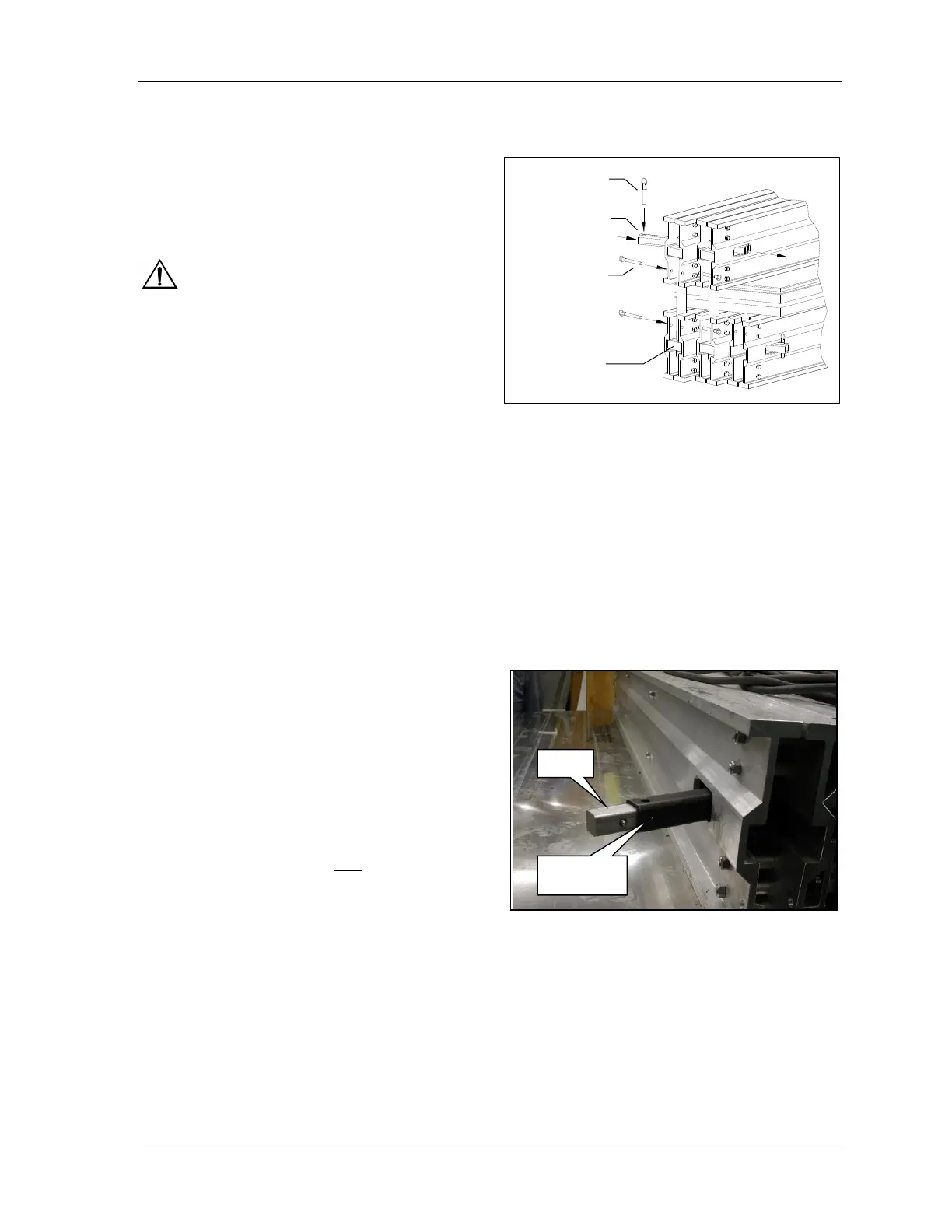

4.6. Assembly of Multiple Platens

Multiple platen Sectional Vulcanizers are designed so the platens can be placed side by side to make a larger

platen area. The assembly procedure is the same as described above, with the following additions.

1. The template will be in more than one section on arrangements over 96” (2.4 m).

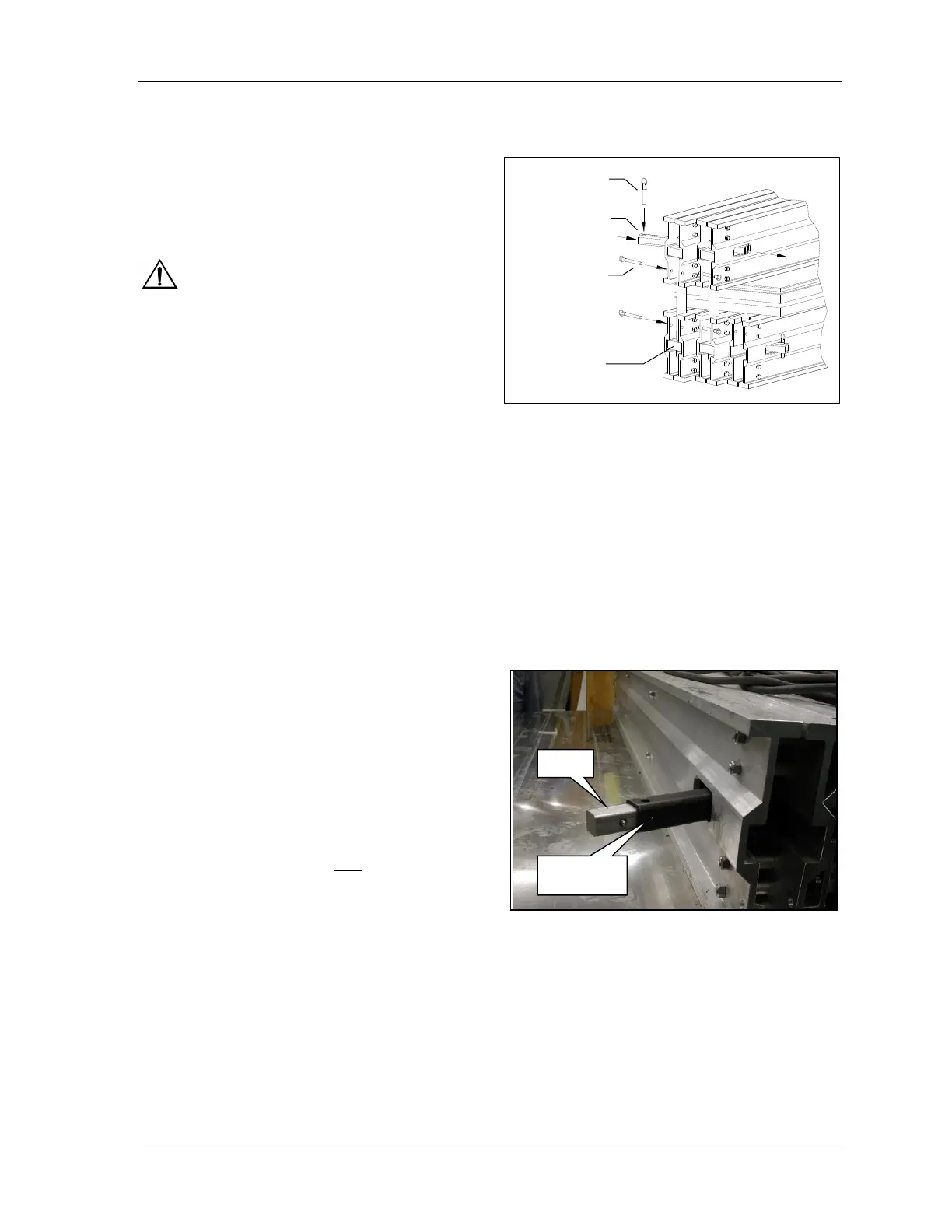

2. The restraining bar will be in more than one section

on arrangements over 96” (2.4 m). Join the

restraining bar sections using the union as shown.

The union is properly installed when the spring

plunger is engaged in the countersunk hole. Install

the lower restraining bars as the traverse bars are

moved into position because it can become difficult

if the traverse bars are not at the same height.

3. Install the lower platens on the lower bars with the

edges tight together.

Tip: It is good practice to use two 1/8 inch (3 mm) steel

plates the same size as the total platen area when

splicing with multiple platens. One plate is used on

top of the lower platens and the other plate is used

on top of the belt (below the upper platens). The

steel plates ensure that no rubber flows between the platen joint. Always try to locate the pressure bags so

that the joint between bags does not coincide with the joint between platens.

4. Install the upper platens aligned with the lower platens and with the edges tight together. The insulation is

made smaller than the platen so the platen edges come together. Be sure that the gap between the platen

insulating panels does not exceed 3/8” (9 mm) or the bag will try to expand into the gap.

5. Install the pressure bags so the valves are on the same side or as close as possible. Always try to locate the

pressure bags so that the joint between bags does not coincide with the joint between platens. When platens

are all the same size on multiple arrangements, two half bags will be supplied so the bag and platen joint do

not coincide.

Loading...

Loading...