4

Alpha InTec² 26CE, 30CE and 35CE

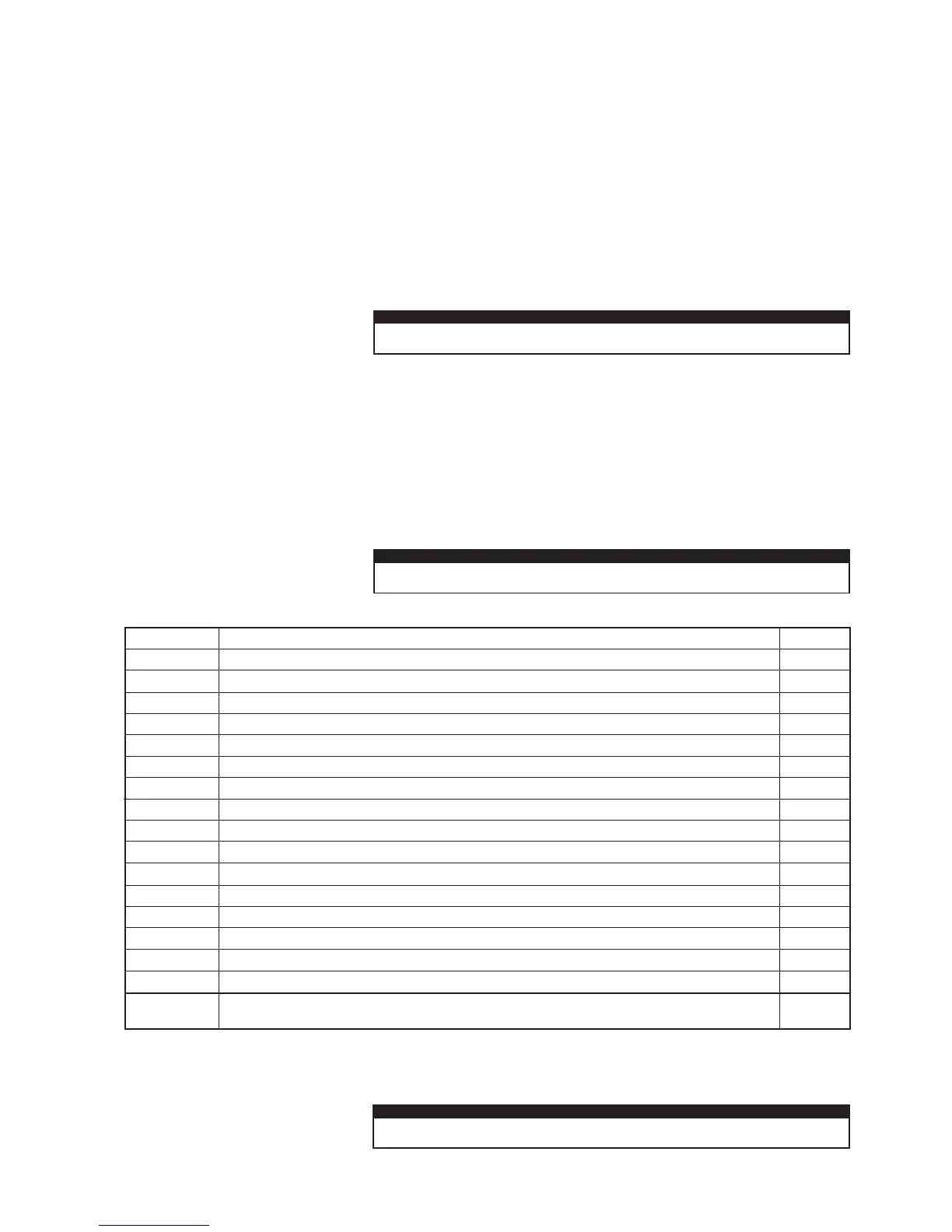

By pressing the info button (item 4 in Fig. 1) the information menu is accessed this will then show the information according

to the table below.

6 FROST PROTECTION

7 CONDENSATE DRAINAGE

High efficiency (condensing) boilers remove more useful heat from the combustion gases, resulting in additional water vapour

which is collected within the boiler (as condensate) and run to a suitable drainage point via the condensate drainage pipe.

Where possible the condensate drain should be connected internally to a waste pipe within the property to prevent the risk of

freezing.

If the condensate drain pipe runs outside it should be fitted with increased diameter pipe and be suitably lagged to reduce

the risk from freezing.

In situations where there are likely to be extremes of temperature or wind-chill the use of a proprietary trace-heating system

for external condensate drainage pipework, incorporating an external frost thermostat, should be considered.

5 INFORMATION MENU

The boiler has a built in frost protection function to protect the boiler (only) from freezing. If water within the boiler falls below

4°C the boiler will fire in heating mode and raise the temperature of the heating water (in the boiler only) to 30°C.

For this function to be active the gas and electricity supplies to the boiler must be turned on and the boiler be in either

'Standby' or 'On' mode.

Further protection for the mains water supply and heating circuit must be provided separately.

If Alpha external controls are fitted, a frost protection setting is incorporated into the room thermostat activating the central

heating when the temperature falls below 5°C.

Info Menu

(d - prefix)

d0

d1

d2

d3

d4

d5

d6

d7

d8

d9

d10

d11

d12

d13

d14

d15

d16

Information

Not used

Flame signal

Central heating water temperature leaving the boiler

Domestic hot water temperature leaving the boiler

Central heating set point temperature

Domestic hot water set point temperature

External weather compensation probe temperature (value flashes if negative)

Mains inlet temperature or FlowSmart cylinder temperature (if sensor fitted)

Not used

Fault history - by rotating the CH knob (item 6 in Fig. 5.1) in this menu the last five faults will be displayed

Fault history reset - when in this menu, pressing the reset button will clear the fault code history

Overheat sensor reading

Pump speed (0 = OFF, 1,2,3,4,5,6,7,8,9)

Not used

CH flow

Fan speed during current operation

Flue sensor reading

Units

Shown

kOhm/10

°C

°C

°C

°C

°C

°C

Error code

°C

Speed level

l/h/100

rpm/100

°C

Loading...

Loading...