16

Alpha Pro Tec - General Boiler Information

3.11 DISPOSAL OF CONDENSATE

Provision must be made for the safe disposal of condensate produced by Alpha Pro Tec boilers and reference should be

made to BS 6798: 2000 for the requirements on the disposal of condensate.

The boilers incorporate a condensate trap which has a seal greater than 75 mm, therefore no additional trap is required.

The condensate should ideally be discharged internally into an internal waste pipe or soil pipe to avoid the possible risk of

freezing. The pipework must be in at least 22 mm pipe.

External pipe runs should be avoided, but if it is necessary, the pipework should be at least 32 mm and protected from the

risk of freezing with waterproof insulation and the length should be kept to a maximum of 3 m. Termination should be into an

external gulley or soakaway as shown in Figs. 3.6 and 3.7.

Note: All pipework must have a continuous fall (see Figs. 3.6 and 3.7) from the boiler and must be of an acid resistant

material such as plastic waste pipe, (copper or steel is not suitable).

It should be noted that the connection of a condensate pipe to a drain may be subject to local building control requirements.

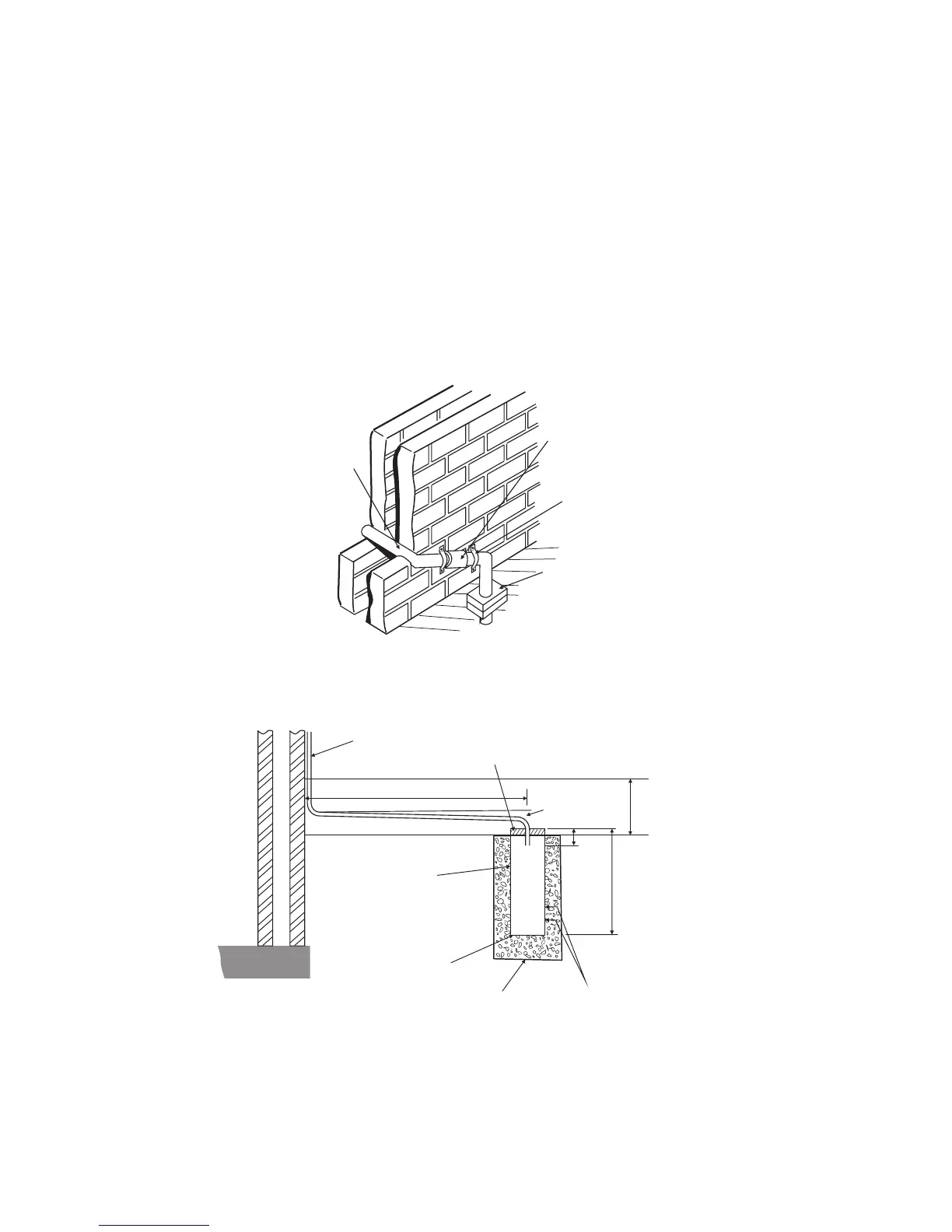

Fig. 3.7 - External soakaway

Ground level (either/or)

22mm termination

from boiler

2½ fall

O

25mm

300mm

Two rows of 3 x 12mm

holes at 25mm centres,

50mm from the bottom

of the tube. Holes to face

away from house.

Cement mortar

sealing

100mm plastic tube

Bottom of tube sealed

Soakaway depth 400mm

filled with limestone chippings

500 mm min.

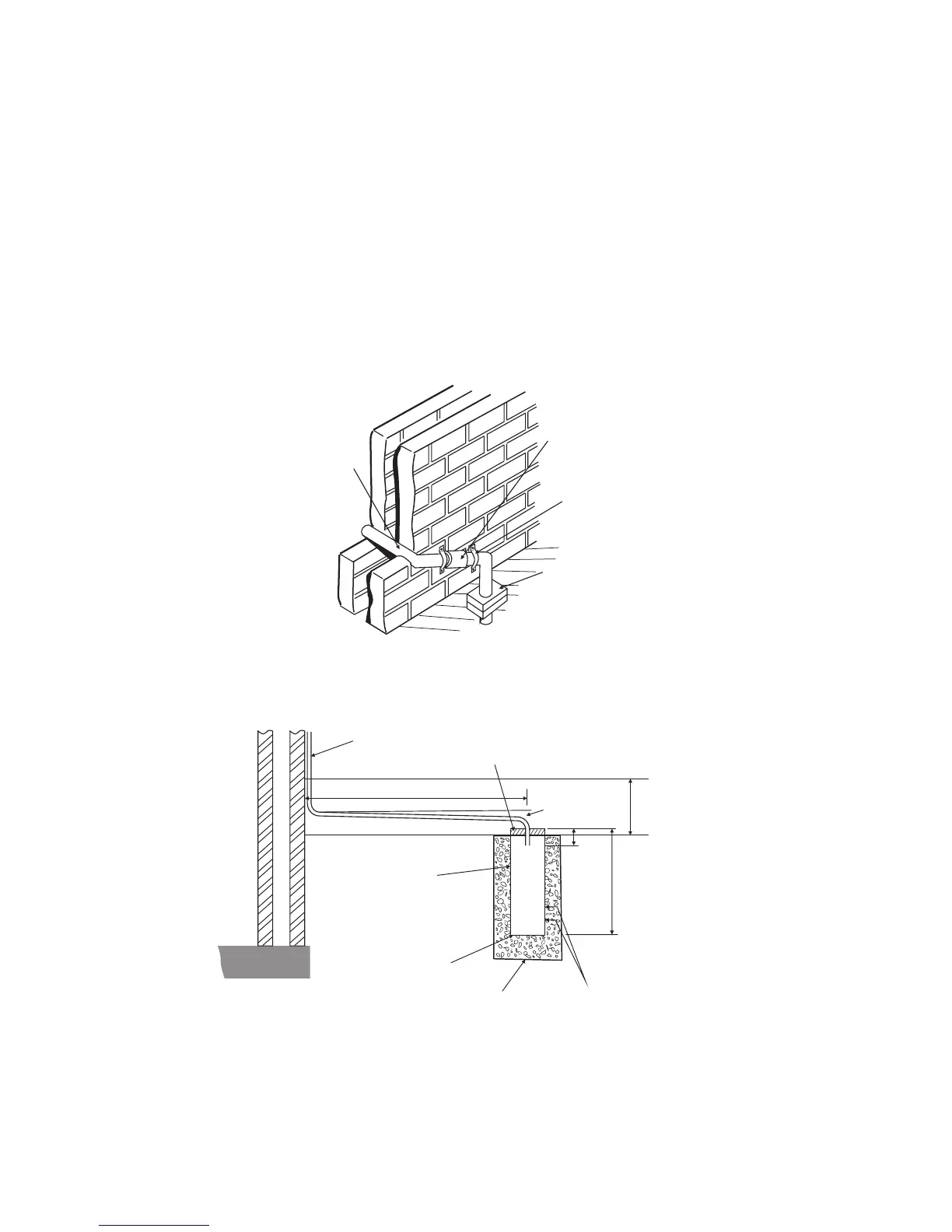

Fig. 3.6 - External gully

Open end of pipe

diverted into gully

below grid but above

water level

Use waterproof

pipework insulation

in very exposed

positions

Ensure pipe is

adequately supported

Plastic pipe

Minimum gradient 2½°

Loading...

Loading...