18

4.3 PREPARE THE WALL - Fig. 4.3

1. Decide upon the position of the boiler taking into account the clearances

required for servicing (refer to Section 2.2) and the ue terminal position.

2. Tape the template to the wall (ensure it is level and the right way up)

and mark the position of the two holes for the boiler mounting hooks.

3. Drill the xing holes (12 mm dia.) to accept the No. 12 plugs supplied.

Screw the boiler mounting hooks fully into the plugs.

4. Cut suitable holes in the wall/roof 100 mm dia for open ue 80 mm dia.

pipe or 127 mm dia. for concentric ue. Use the centre line positions

given on the ue template.

For side ue follow the horizontal line (ensuring at least a 25 mm/m

fall towards the boiler) to the corner then 140 mm along the side wall

to the centre of the hole for the ue.

5. Lift the boiler and locate it on the mounting hooks.

Note: When handling or lifting always use safe techniques - keep your

back straight, bend your knees, don't twist - move your feet, avoid

bending forwards and sideways and keep the load as close to your body

as possible.

Where possible transport the boiler using a sack truck or other suitable trolley.

Always grip the boiler rmly, and before lifting feel where the weight is

concentrated to establish the centre of gravity, repositioning yourself as

necessary.

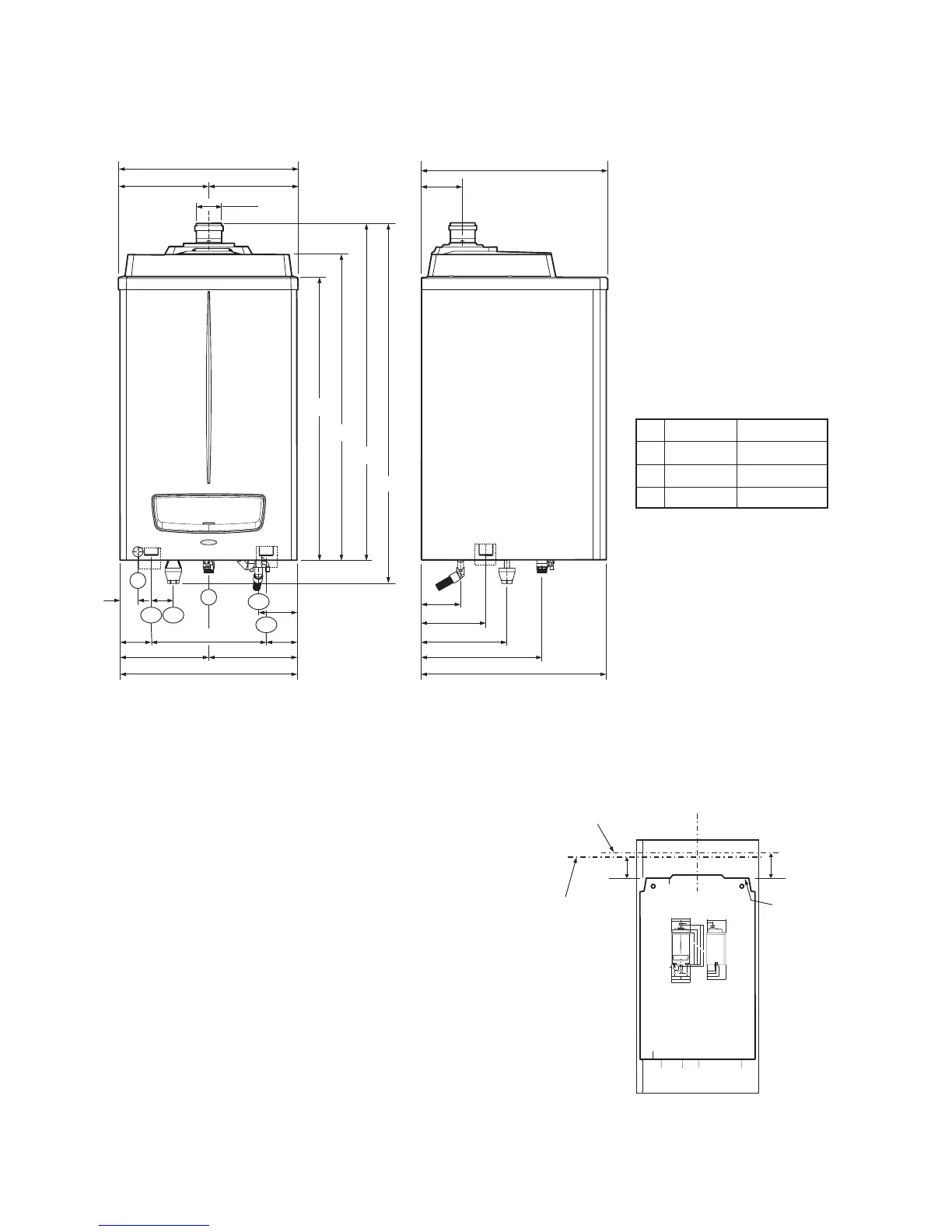

Fig. 4.2

4.2.2 Pro Tec 70, 90, 115

A

B

C

Pro Tec 70

502 mm

265 mm

497 mm

Pro Tec 90, 115

632 mm

410 mm

627 mm

SV

HF

HR

80 Dia.

60

G

CD

E

608

304304

140

A

134

220

291

B

C

960

1038

1140

1219

75

105 390

300

600

300

105

131

E - Electrical connection

G - Gas supply

HR - Heating return

HF - Heating ow

CD - Condensate drain

SV - Safety valve outlet (tundish)

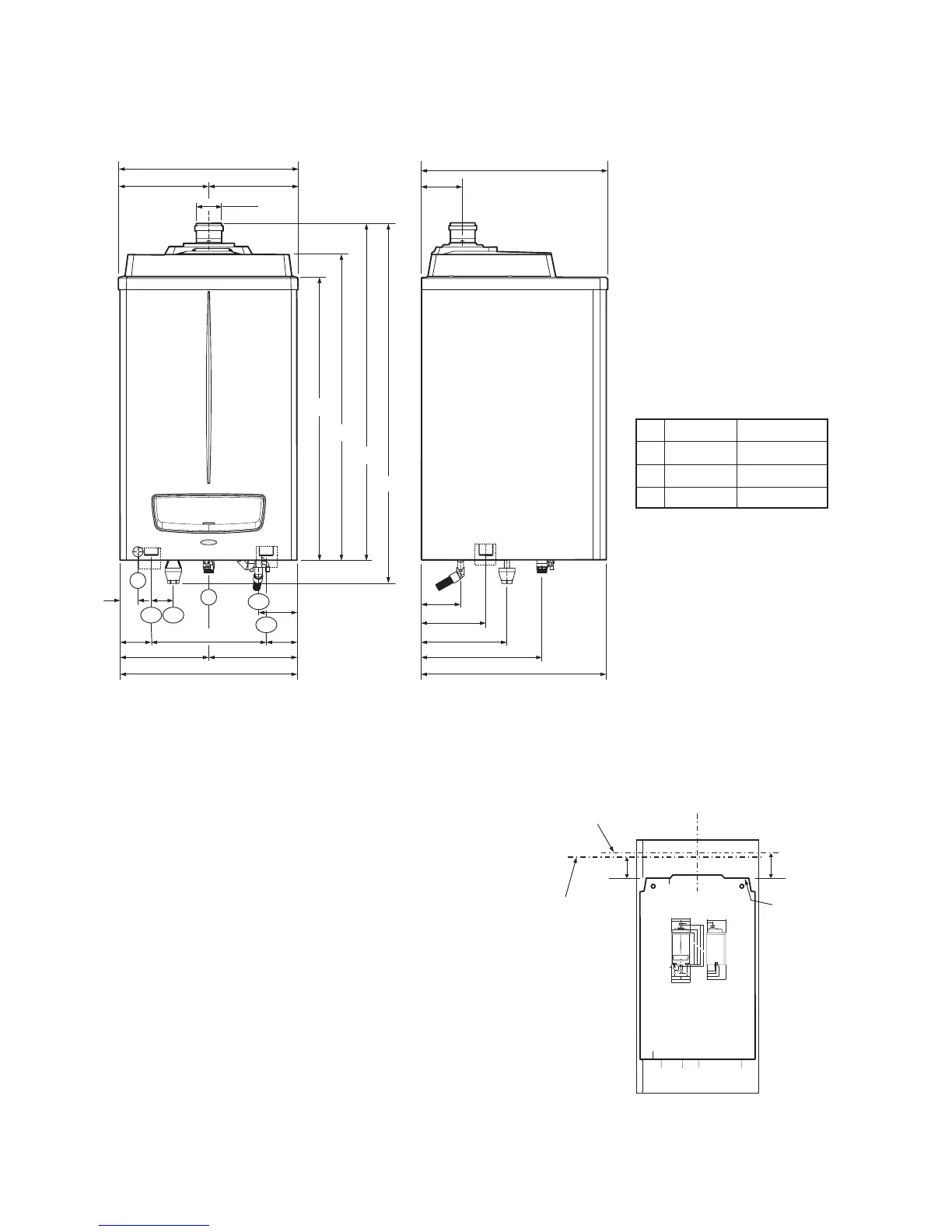

Fig. 4.3

Centre line for

vertical flues

Centre line

for horizontal

concentric flue

Centre line

for horizontal

open flue

Loading...

Loading...