Driven Pulley

With cab removed, grease the driven

pulley shaft as follows:

Remove pulley guard and slip

off

drive

belt. Open the driven pulley, (push and

twist sliding half).

Thoroughly clean the driven pulley

shaft.

Apply a

light coat of low-temp grease

on the shaft. Always lubricate lightly

and wipe

off

surplus.

O

NOTE: Activate the sliding half

several times to distribute lubri-

cant over full length of shaft. Be care-

ful that lubricant does not get on inner

halvesof pulley.

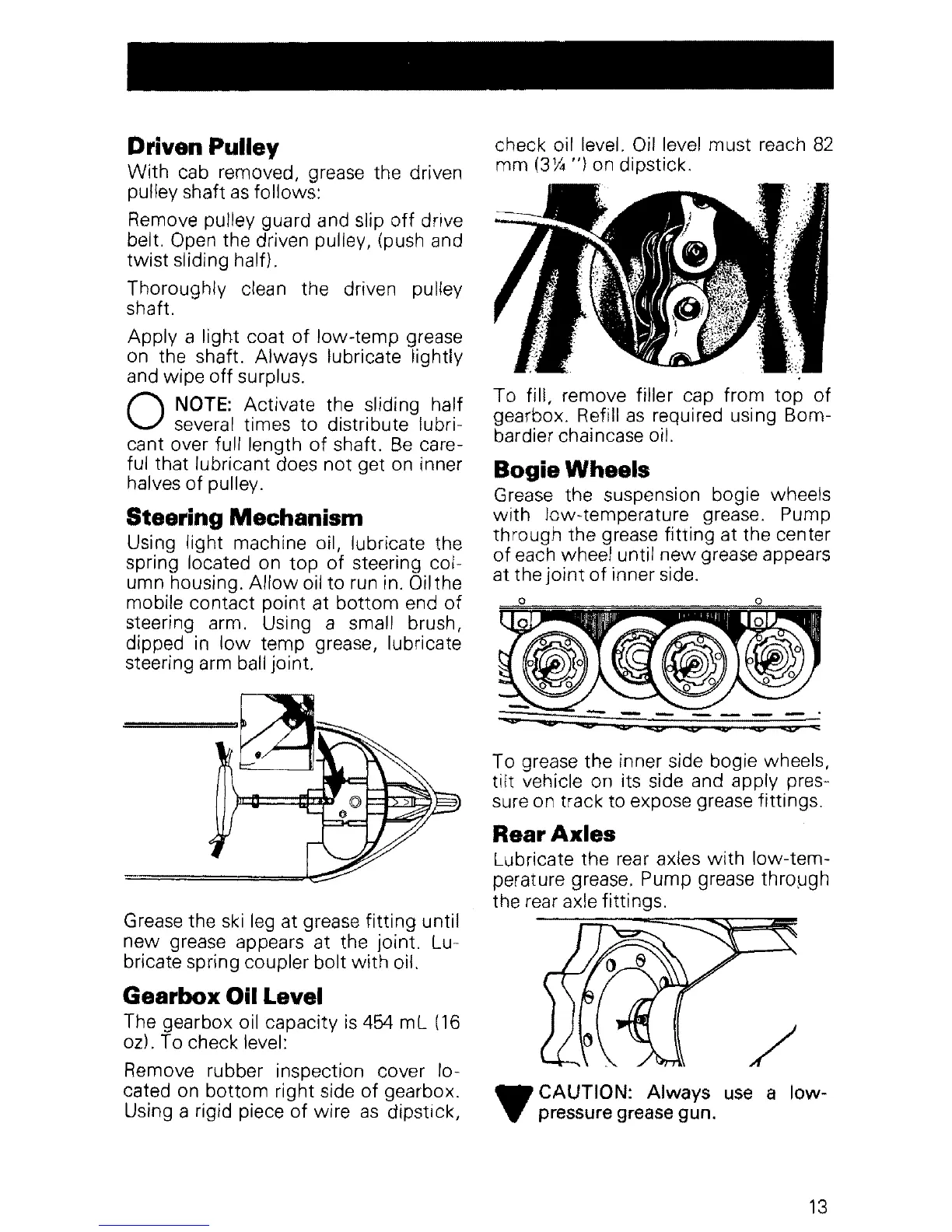

Steering

Mechanism

Using light machine oil, lubricate the

spring located on top of steering col-

umn housing. Allow

oil to run in. Oilthe

mobile contact point at bottom end of

steering arm. Using a small brush,

dipped in

low

temp grease, lubricate

steering arm ball joint.

Greasethe ski leg at grease fitting until

new grease appears at the joint. Lu-

bricate spring coupler bolt with oil.

Gearbox Oil Level

The gearbox oil capacity is 454 mL (16

oz). To check level:

Remove rubber inspection cover lo-

cated on bottom right side of gearbox.

Using a

rigid piece of wire as dipstick,

check oil level. Oil level must reach 82

mm

(314

") on dipstick.

To fill, remove filler cap from top of

gearbox. Refill as required using Bom-

bardier chaincase oil.

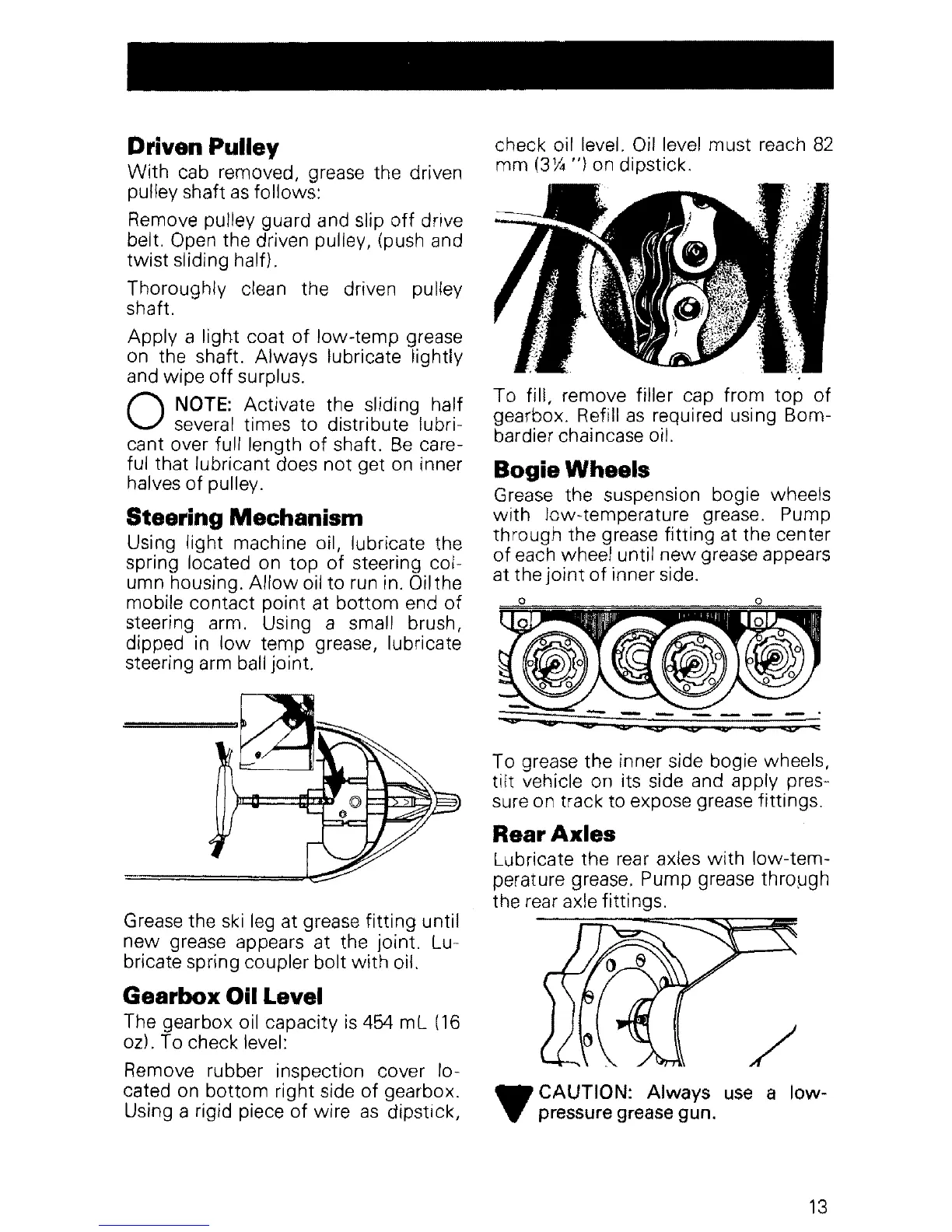

Bogie Wheels

Grease

the suspension bogie wheels

with low-temperature grease. Pump

through the grease fitting at the center

of each wheel until new grease appears

at the joint of inner side.

To grease the inner side bogie wheels,

tilt vehicle on its side and apply pres-

sure on track to expose greasefittings.

Rear

Axles

Lubricate the rear axles with low-tem-

perature grease. Pump grease

throuqn

the rear axle fittings.

/

...

CAUTION: Always use a low-

...

pressure greasegun.

13

Loading...

Loading...