23

TROUBLESHOOTING

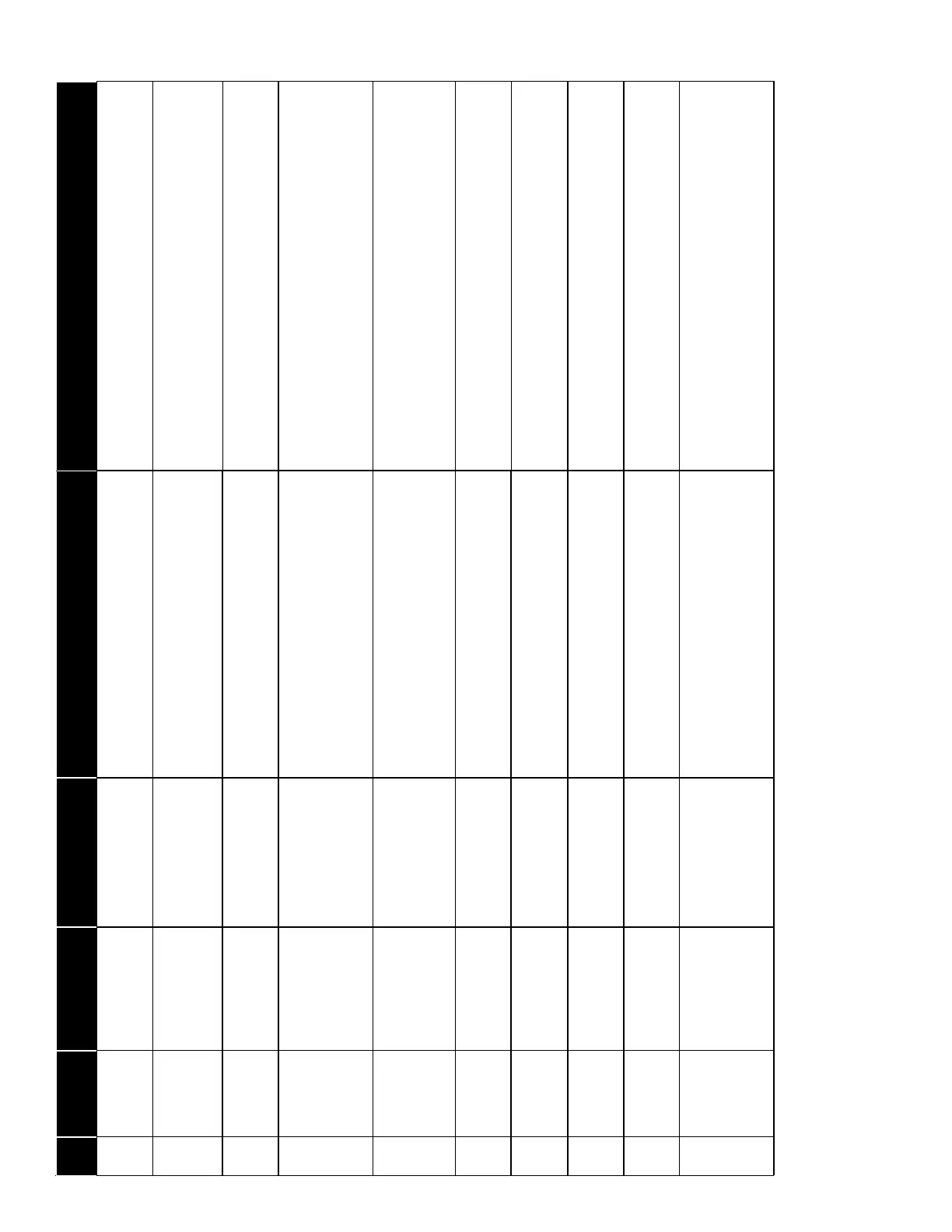

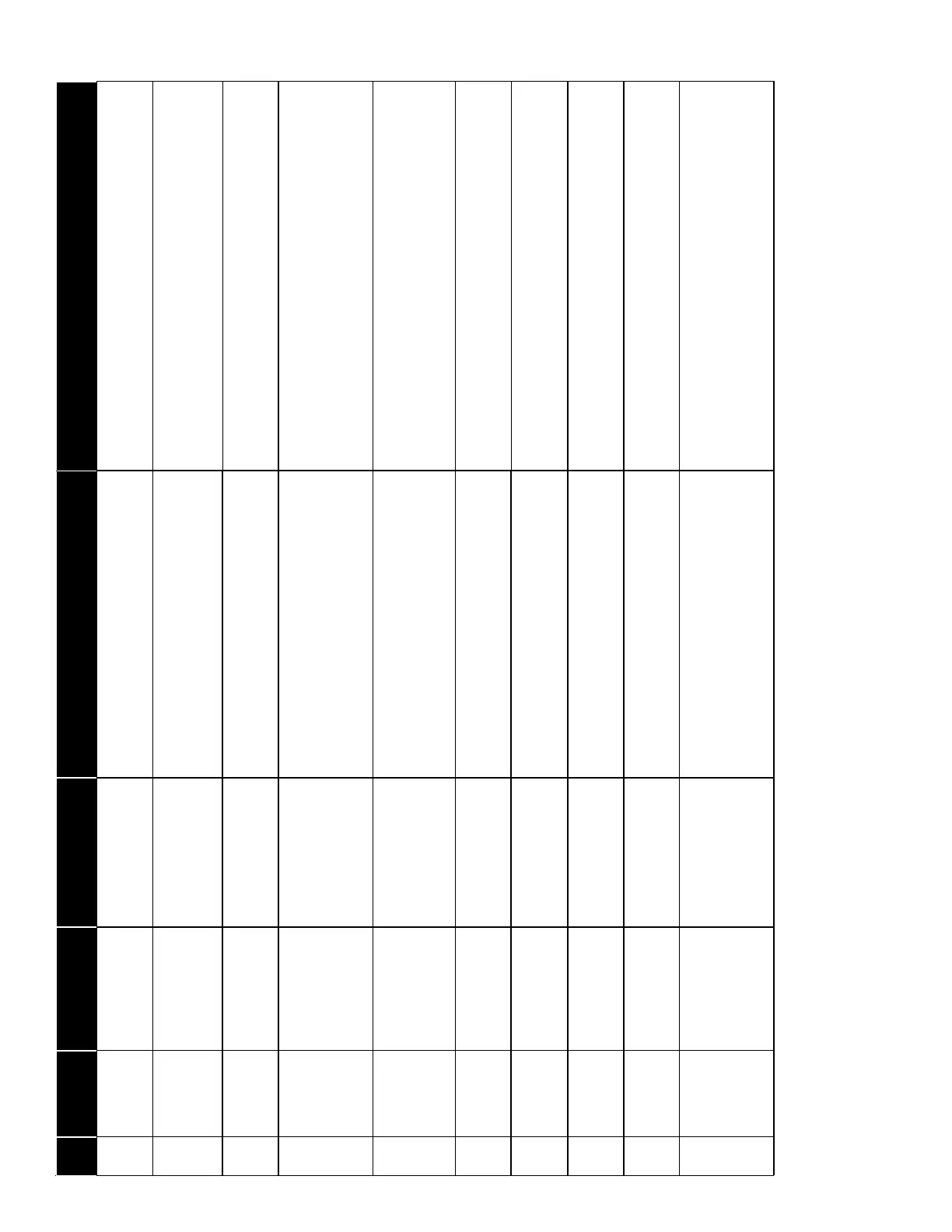

b4 E_b4

BLower Motor Trip

or Lost Rotor

(MOTOR TRIPS)

Blower Motor -

Current Trip (or) Lost Rotor

• Fan/motor obstruction or abnormal motor loading

• Power interruption (low voltage)

• High loading conditions, blocked filters

• Blockage in the airflow (ductwork) or ductwork undersized

b6 E_b6

Voltage or Temperature Trip

(MOTOR VOLTS)

• Blower motor stops for over/under

voltage

• Bower motor stops due to PCB

over heating

• High AC line voltage to ID blower

• Low AC line voltage to ID blower

• High ambient temperatures

• Incorrect wiring

• Fan/motor obstruction or blockage in the airflow

b7 E_b7

Incomplete Parameters

Sent to Motor

(MOTOR PARAMS)

ID blower motor does not have

required parameters to function.

• Wrong / no shared data on the network

• Locked motor rotor condition

b9 E_b9 No Display

Low Indoor Airflow

(without Electric Heat mode)

• Fan/motor obstruction or blocked filters

• Restrictive ductwork or ductwork undersized

• W iring disconnected

• Wrong outdoor/indoor combination

• ID motor failure

9b E_9b LOW ID AIR EH MODE

Low Indoor Airflow

(with Electric Heat mode)

• Fan/motor obstruction or blocked filters

• Restrictive ductwork or ductwork undersized

• ID motor failure

• W iring disconnected

70 E_70 EEV OPEN CKT EEV disconnection detected

• Indoor EEV coil not connected

• Incorrect wiring to EEV

73 E_73 LIQ TEMP FLT Liquid side thermistor abnormality

• Open (or) short circuit of the liquid thermistor (X5A)

• Liquid thermistor reading incorrect or values outside the normal range

74 E_74 GAS TEMP FLT Gas side thermistor abnormality

• Open (or) short circuit of the gas thermistor (X5A)

• Gas thermistor reading incorrect or values outside the normal range

75 E_75 PRESSURE FLT Pressure sensor abnormality

• Open (or) short circuit of the Pressure sensor (X15A)

• Pressure sensor reading incorrect or values outside the normal range

77 E_77 TSTAT ID NO COM

Indoor Unit - Thermostat

communication error

(start-up & during operation)

• Incorrect wiring between ID unit and thermostat.

The system may have the communication error without error code 77

on the indoor PCB. Follow section 16.6 SYSTEM TROUBLESHOOTING

• Thermostat failure

• Power interruption (low voltage)

Error

Code

De sc ri pti on Possi bl e Ca use sClimateTalk MessagePCB LED Display

• Check for obstruction on the fan/motor/ductwork

• Verify the input voltage at the motor

• Check filters, grills, duct system, coil air inlet/outlet for blockages.

• Replace motor

• Verify line voltage to blower is within the range specified on the ID blower rating plate

• See "Installation Instructions" for installation requirements

• Check power to air handler blower

• Check for obstruction on the fan/motor/ductwork

• Check wiring

• Replace motor

• Check for locked rotor condition (see above error code for details)

• Replace circuit board or motor

• Check for obstruction on the fan/motor

• Check ductwork/filter for blockage, clean filters

• Remove obstruction. Verify all registers are fully open

• Check the connections and the rotation of the motor

• Verify the input voltage at the motor

• Verify ductwork is appropriately sized for system. Resize/replace ductwork if needed

• Replace motor

• Check for obstruction on the fan/motor

• Check ductwork/filter for blockage, clean filters

• Remove obstruction. Verify all registers are fully open

• Check the connections and the rotation of the motor

• Verify the input voltage at the motor

• Verify ductwork is appropriately sized for system. Resize/replace ductwork if needed

• Replace motor

• Check Indoor EEV coil connection (PCB and junction connector)

• Replace EEV coil

• Check the resistance value of EEV coil (refer service manual)

• Replace the control board

• Check the connection to liquid thermistor (PCB and junction connector)

• Check the resistance value of the thermistor (refer service manual)

• Replace thermistor

• Replace the control board

• Check the connection to gas thermistor (PCB and junction connector)

• Check the resistance value of the thermistor (refer service manual)

• Replace thermistor

• Replace the control board

• Check the connection to pressure sensor (PCB and junction connector)

• Check the output voltage of the pressure sensor (refer service manual)

• Replace pressure sensor

• Replace the control board

• Check for thermostat and indoor unit wiring

• Verify the input voltage at the ID unit and thermostat

After recovering the system with power supply, TSTAT ID NO COM will continue to be

displayed on the thermostat within 2 minutes. The error code will be cleared automatically.

• Replace control board or thermostat

• Press "LEARN" button on PCB for more than 5 seconds to reestablish network

Corre ctive Actions

Loading...

Loading...