19

A

VOID

CONTACT

WITH

THE

CHARGED

AREA

.

•N

EVER

TOUCH

THE

CHARGED

AREA

BEFORE

CONFIRMING

THAT

THE

RESIDUAL

VOLTAGE

IS

50

VOLTS

OR

LESS

.

1. S

HUT

DOWN

THE

POWER

AND

LEAVE

THE

CONTROL

BOX

FOR

10

MINUTES

.

2. M

AKE

SURE

TO

TOUCH

THE

E

ARTH

GROUND

TERMINAL

TO

RELEASE

THE

STATIC

ELECTRICITY

FROM

YOUR

BODY

(

TO

PREVENT

FAILURE

OF

THE

PC

BOARD

).

3. M

EASURE

THE

RESIDUAL

VOLTAGE

IN

THE

SPECIFIED

MEASUREMENT

POSITION

USING

A

VOM

WHILE

PAYING

ATTENTION

NOT

TO

TOUCH

THE

CHARGED

AREA

.

4. I

MMEDIATELY

AFTER

MEASURING

THE

RESIDUAL

VOLTAGE

,

DISCONNECT

THE

CONNECTORS

OF

THE

OUTDOOR

UNIT

’

S

FAN

MOTOR

. (I

F

THE

FAN

BLADE

ROTATES

BY

STRONG

WIND

BLOWING

AGAINST

IT

,

THE

CAPACITOR

WILL BE CHARGED,

CAUSING

THE

DANGER

OF

ELECTRICAL

SHOCK

.)

WARNING

TROUBLESHOOTING

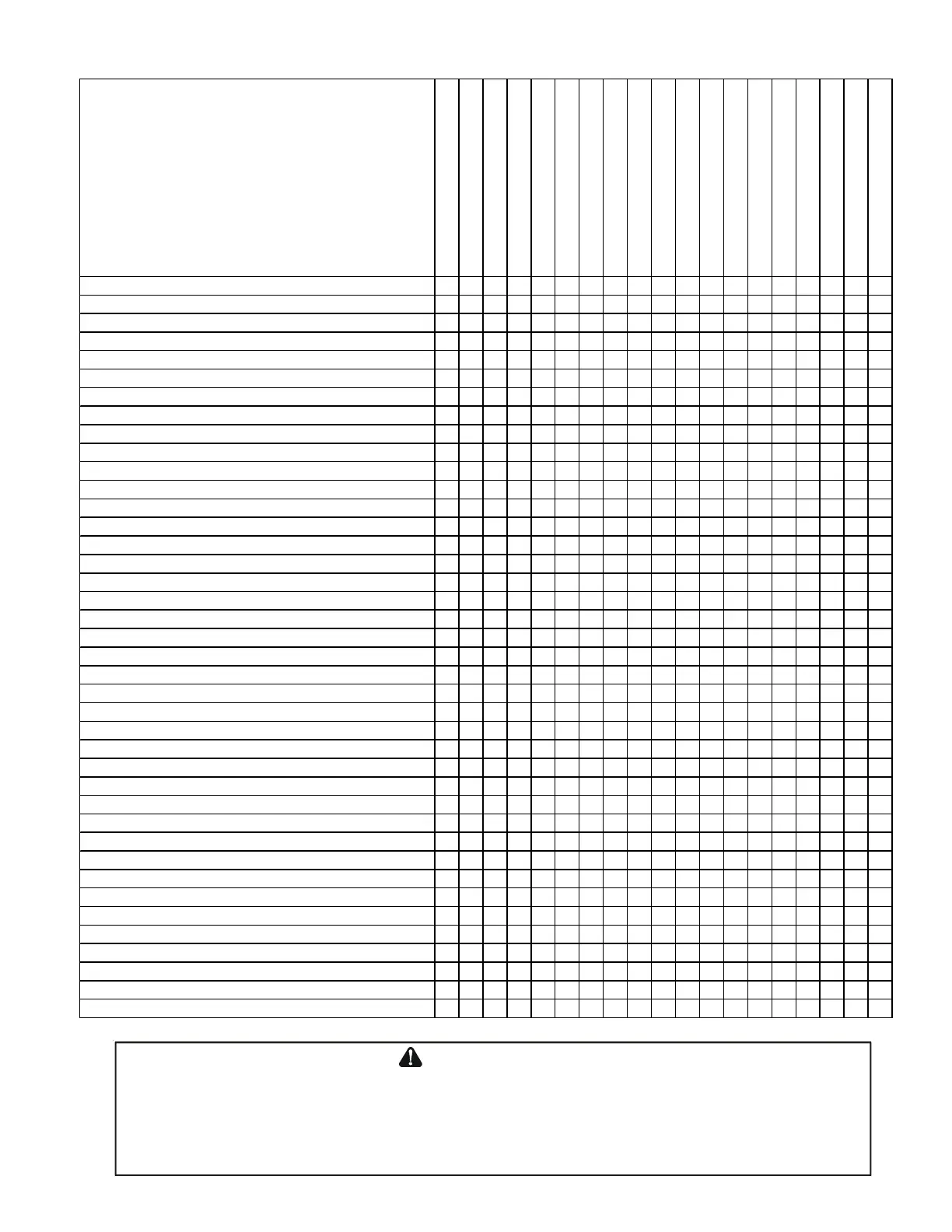

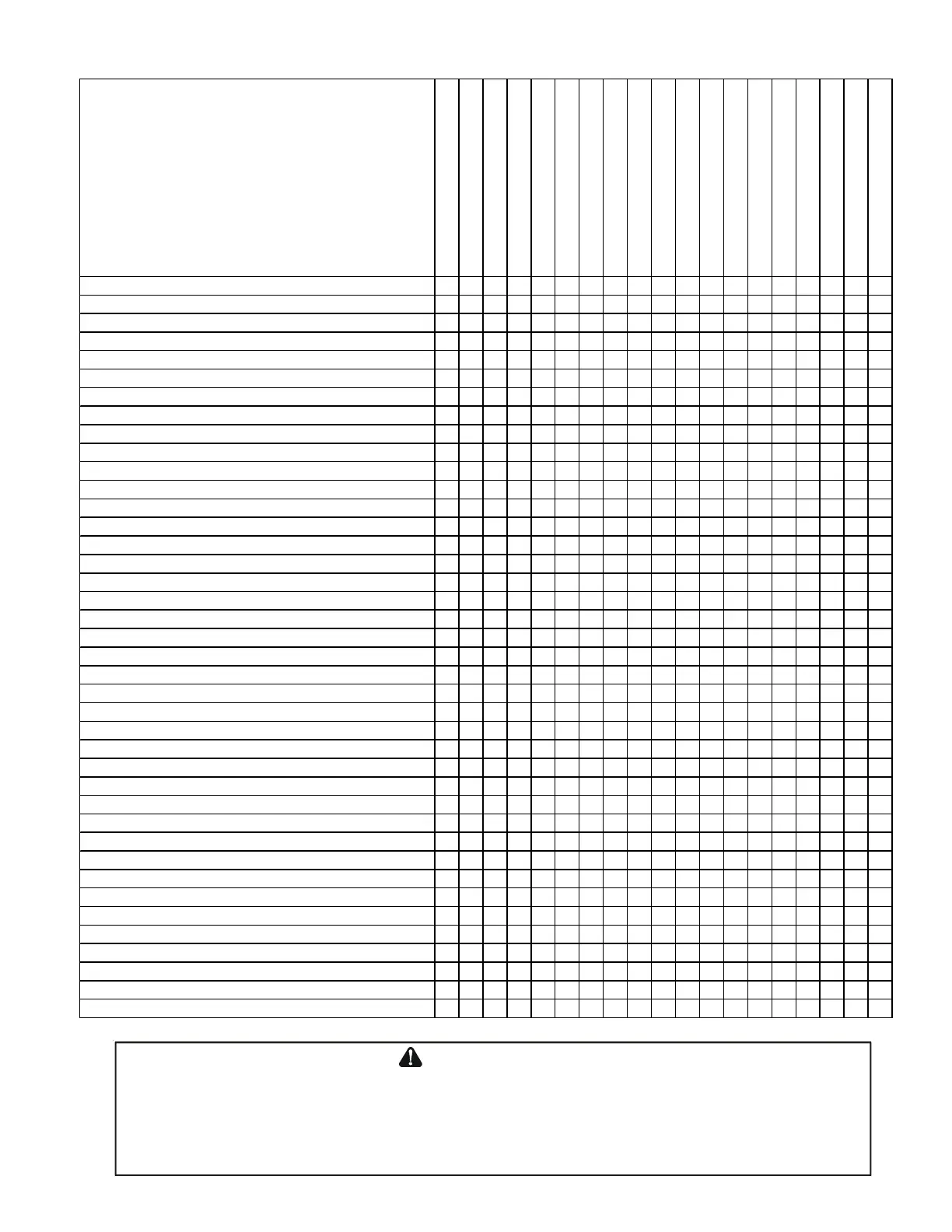

Outdoor Normal Temperature Operating Range: 17-62° / Indoor Normal Temperature Operating Range: 65 - 85°

POSSIBLE CAUSE

X IN ANALYSIS GUIDE INDICATE

"POSSIBLE CAUSE"

Comp discharge temp > 200F

Comp discharge temp < 105F

Comp discharge SH > 70F

Comp discharge SH < 20F

High pressure > 490psi

High pressure SSV< 270psi

High pressure LSV< 270psi

LSV SC > 12F

LSV SC < 4F

Low pressure < 40psi

Requested % demand < Actual %

Requested % demand > Actual %

Repeated stop/start

Weak heating

No switch heating

Noise

Incomplete defrost operation

Stop operation

Sweating liquid line

Liquid stop valve does not fully open

XXX XXXXX XX

Gas stop valve does not fully open

X X X XX XXX X

Line set restriction

X X X XX XXX X X

Line set length is too long

XX X

Blocked filter-dryer

X X X XX XXX X X

OD EEV coil failure

XXXXXXXXXXXXXX XX

OD EEV failure

XXXXXXXXXXXXXX XX

Check valve failure – Leakage

XX XXXX X

High Pressure switch failure

X

Pressure sensor failure

XXXXXXX XXXX X

Discharge temp sensor failure

XXXX XXXX X

Coil temp sensor failure

X XXX XX

Defrost sensor failure

X XXX XX

Liquid temp sensor failure

XX XX

Ambient temp sensor failure

X X XXX XX

OD recirculation

X X XX X XXX

ID recirculation

XXX XXX

Dirty OD Heat-exchanger

X X XX X XXX

Dirty ID Heat-exchanger

XXX XXX

Outdoor Ambient temp is too high

X XXX XX

Outdoor Ambient temp is too low

XXX XX XX XXX

ID suction temp is too high

X X XXX

ID suction temp is too low

XX X

Mixture of non-condensible gas

X X X XX XXX

OD fan motor failure

XX XXXX X

RV failure

X XX XXXX XX

RV coil failure

X XX XXXX XX

Over charge

XXX X XXXX XX

Under charge

XXX XX XX XX X

Leak

XXX XX XX XX X

TXV failure

X X X XX XXX

TXV size is small

X

TXV size is big

ID failure

XXXXXXXXXXXXXX XXXX

OD Control Board failure

X

Compressor failure

XXXX XX XXX XXX

Cooling loop is not attached

XXX

Cooling loop grease is not enough

XXX

Compressor and Gas furnace are operating at the same time

XX

Low ID CFM

X X X XXX X

HEATING ANALYSIS CHART

Loading...

Loading...