Maintenance, repair and care

BAG0014.4 09.14

12.3 Maintenance and care - Review

• Carry out maintenance in the shortest mentioned intervals.

● Give priority to the intervals, running times and maintenance

intervals stated in the possibly provided documentation of other

manufacturers.

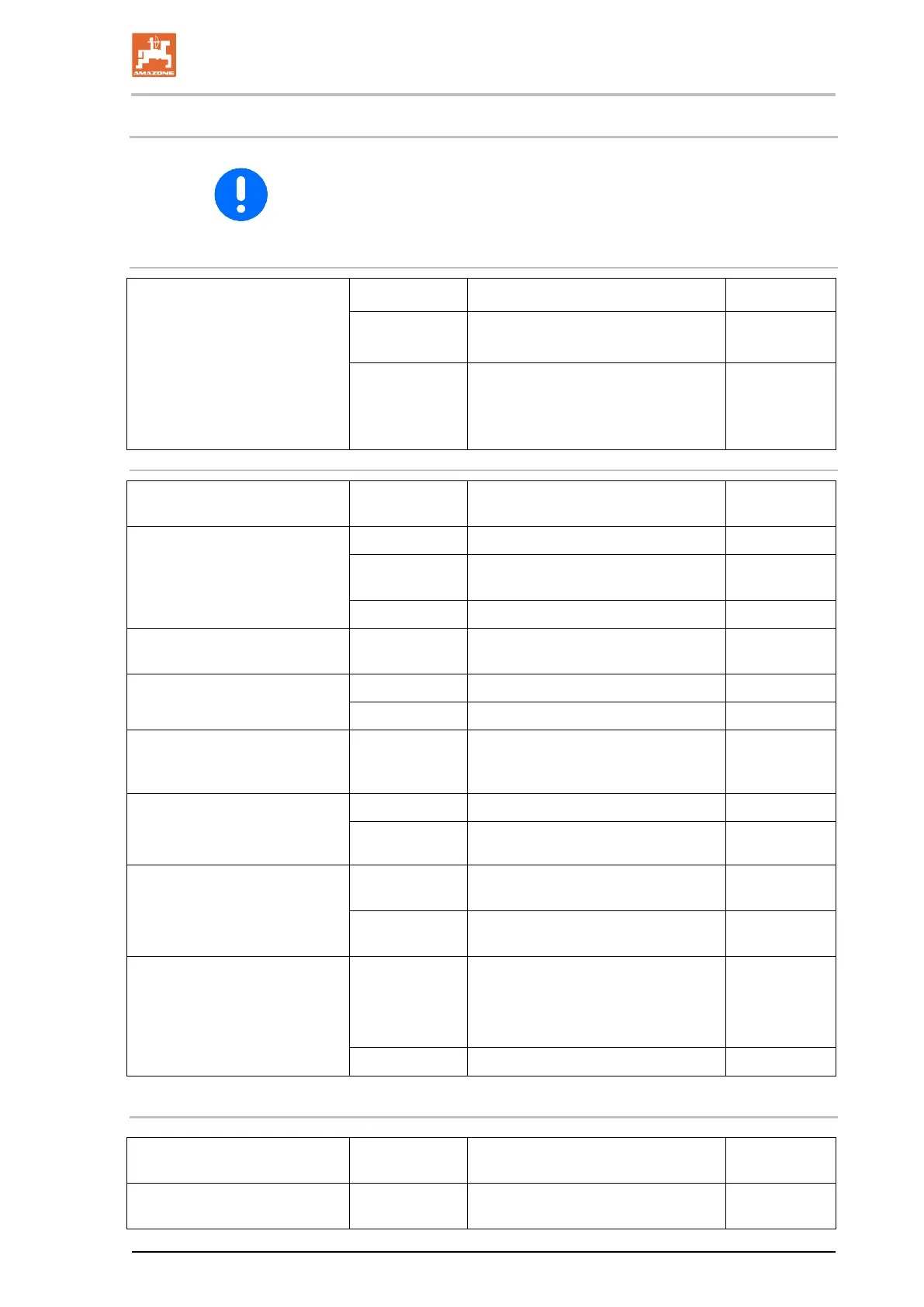

Maintenance before operation

Maintenance before opera-

tion

Checking the hydraulic hose lines

Checking the oil level in the Vario

gearbox.

Checking whether the tramline

which has been adjusted in the

distributor head corresponds to the

track width of the husbandry tractor.

Maintenance table

work

Drain the air pressure reservoir (Air

brake system)

When refilling the seed box

of hourly

Check the seed placement depth

Check the metering devices for

cleanliness

Check seed hoses for cleanliness

Check distributor heads for cleanli-

ness

Daily after having finished

work

Empty metering devices and clean

Clean the machine (if necessary)

Every week, after every 50

hours of operation at the

latest

Check the hydraulic hose lines

Every 2 weeks, after every

100 operational hours at the

latest

Check tyre pressure

Check oil level in the Vario gearbox

Every 3 months, after every

500 operational hours at the

latest

Inspection of the dual circuit air

brake system

Feststellbremse:Bremswirkung im

angezogenen Zustand kontrollieren

Seite 123

Every 6 months before start

of the season

Checking and servicing the hydrau-

lic hose lines.

The inspection should be recorded

by the operator.

Checking the brake lining thickness

12.3.1 Remedy of function faults and repair work

Changing the tramline bout

width

Seite 133

10 operational hours after

wheel change

Retighten wheel and hub bolts

Seite 131

Loading...

Loading...