18-CE03D1-1F-EN

9

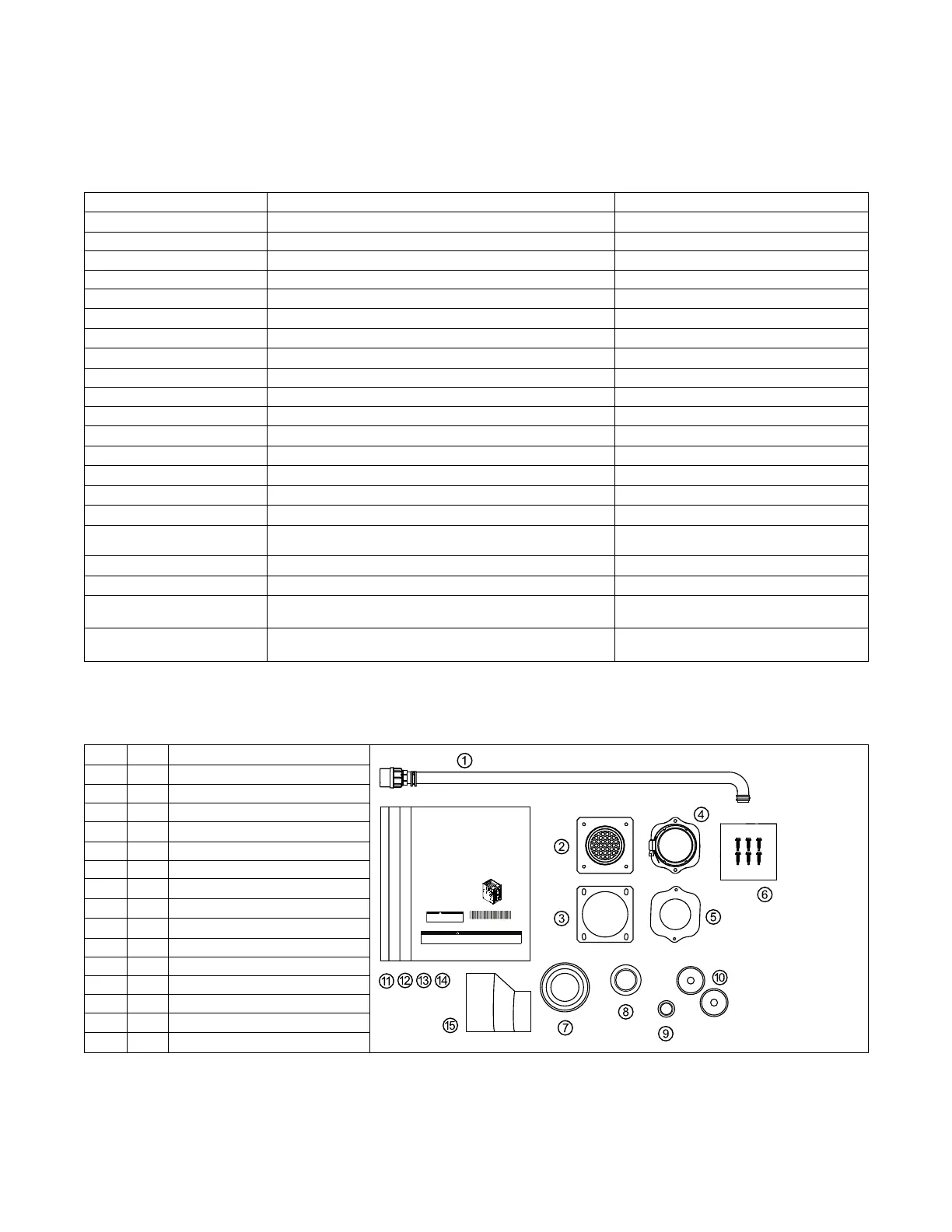

Accessories

Table 1. Accessories

Model Number Description Use with

BAYHANG Horizontal Hanging Kit All Upflow Furnaces

BAYVENT200B Sidewall Vent Termination Kit All Furnaces

BAYVENTCN200B Sidewall Vent Termination Kit (Canada —CPVC) All Furnaces

BAYAIR30AVENTA Concentric Vent Kit All Furnaces

BAYAIR30CNVENT Concentric Vent Kit (Canada — CPVC) All Furnaces

BAYREDUCE Reducing Coupling (CPVC) All Furnaces

BAYLIFTB Dual Return Kit (B size extension) B Cabinet Upflow Furnaces

BAYLIFTC Dual Return Kit (C size extension) C Cabinet Upflow Furnaces

BAYLIFTD

Dual Return Kit (D size extension) D Cabinet Upflow Furnaces

BAYBASE205 Downflow Subbase All Downflow Furnaces

BAYFLTR206 Filter Access Door Kit (Downflow only) All Downflow Furnaces

BAYSF1165AA

(a)

1” SlimFit Box with MERV 4 Filter All Upflow Furnaces

BAYLPSS400* Propane Conversion Kit with Stainless Steel Burners All Furnaces

BAYMFGH200B Manufactured/Mobile Housing Kit All Furnaces

BAYHALT250 High Altitude Pressure Switch Kit S9V2B040U3VSA

BAYHALT251 High Altitude Pressure Switch Kit S9V2B060U3VSA

BAYHALT252 High Altitude Pressure Switch Kit S9V2B080U4VSA, S9V2B080D4VSA,

S9V2C100D4VSA

BAYHALT253 High Altitude Pressure Switch Kit S9V2C100U4VSA

BAYHALT254 High Altitude Pressure Switch Kit S9V2D120U5VSA

BAYCNDTRAP2 Inline Condensate Trap Kit used with Special Venting on 2”

Vent Pipe

All Furnaces

BAYCNDTRAP3 Inline Condensate Trap Kit used with Special Venting on 3”

Vent Pipe

All Furnaces

(a)

Airflow greater than 1600 CFM requires dual returns

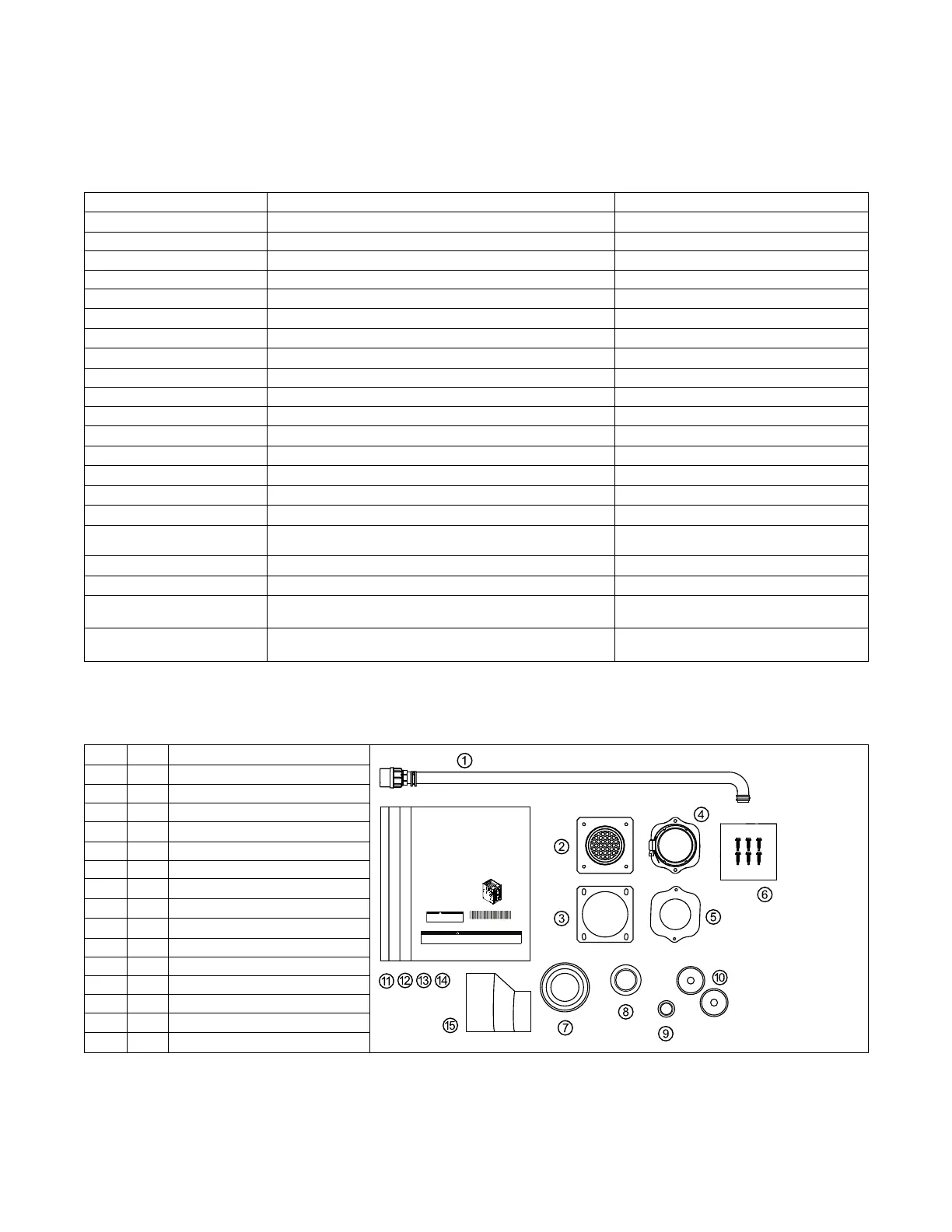

Document Pack Contents S9V2–

VS

Item Qty. Description

SSAAFFEETTYY WWAARRNNIINNGG

Onlyqualified personnelshould installand servicethe equipment.The installation,starting up,and servicingof heating,ventilating, andair-conditioning

equipmentcan behazardous andrequires specificknowledge andtraining. Improperlyinstalled, adjustedor alteredequipment byan unqualifiedperson

couldresult indeath orserious injury.When workingon theequipment, observeall precautionsin theliterature andon thetags, stickers,and labelsthat

areattached tothe equipment.

May 2020

1188--CCEE0033DD11--11FF--EENN

Upow/Horizontal and Dedicated Downow

Gas-Fired, Direct/Non-Direct Vent, 2–Stage

Condensing Variable Speed Furnaces with Variable Speed

Draft Inducer

UUppffllooww,,CCoonnvveerrttiibbllee ttoo

HHoorriizzoonnttaallRRiigghhtt oorr

HHoorriizzoonnttaallLLeefftt

S9V2B040U3VSAB

S9V2B060U3VSAB

S9V2B080U4VSAB

S9V2C100U4VSAB

S9V2D120U5VSAB

DDoowwnnffllooww OOnnllyy

S9V2B080D4VSAB

S9V2C100D4VSAB

NNoottee::Graphics in this document are for representation

only. Actual model may differ in appearance.

▲

CAUTION

!

COIL REQUIREMENT!

Failure to follow this Caution could result in property damage or personal injury. 4GXC* and

4MXC* coils installed on upflow furnaces in vertical, horizontal left, or horizontal right

orientations without a factory installed metal drain pan shield must use a MAY*FERCOLKITAA

kit. Coils installed on upflow furnaces must have drain pans that are suitable for 400° F

(205°C) or have a metal drain pan shield. Downflow furnaces do not require a metal drain pan

shield or the use of the MAY*FERCOLKITAA kit. See Installer’s Guide for more information.

1 1 Condensate Drain Tube Assembly

2 1 Inlet Vent

(a)

3 1 Inlet Vent Gasket

4 1 Outlet Vent Assembly

5 1 Outlet Vent Gasket

6 6 Screws

7 1 Condensate Trap Grommet

8 1 Plug — Condensate/Gas

9 1

Plug — Electrical

10 2 Grommet — Condensate/Gas

11 1 Installer’s Guide

12 1 Service Facts

13 1 Owner Guide

14 1 Limited Warranty

15 1 2” to 3” Coupling — CPL00938

(b)

(a)

3” inlet vent supplied with S9V2D120U5VSA only. 2” inlet vent supplied with all other models.

(b)

Supplied with S9V2D120U5VSA only.

Loading...

Loading...