M O D E L 2 1

O P E R A T

I O N M A N U A L

10

1010

10

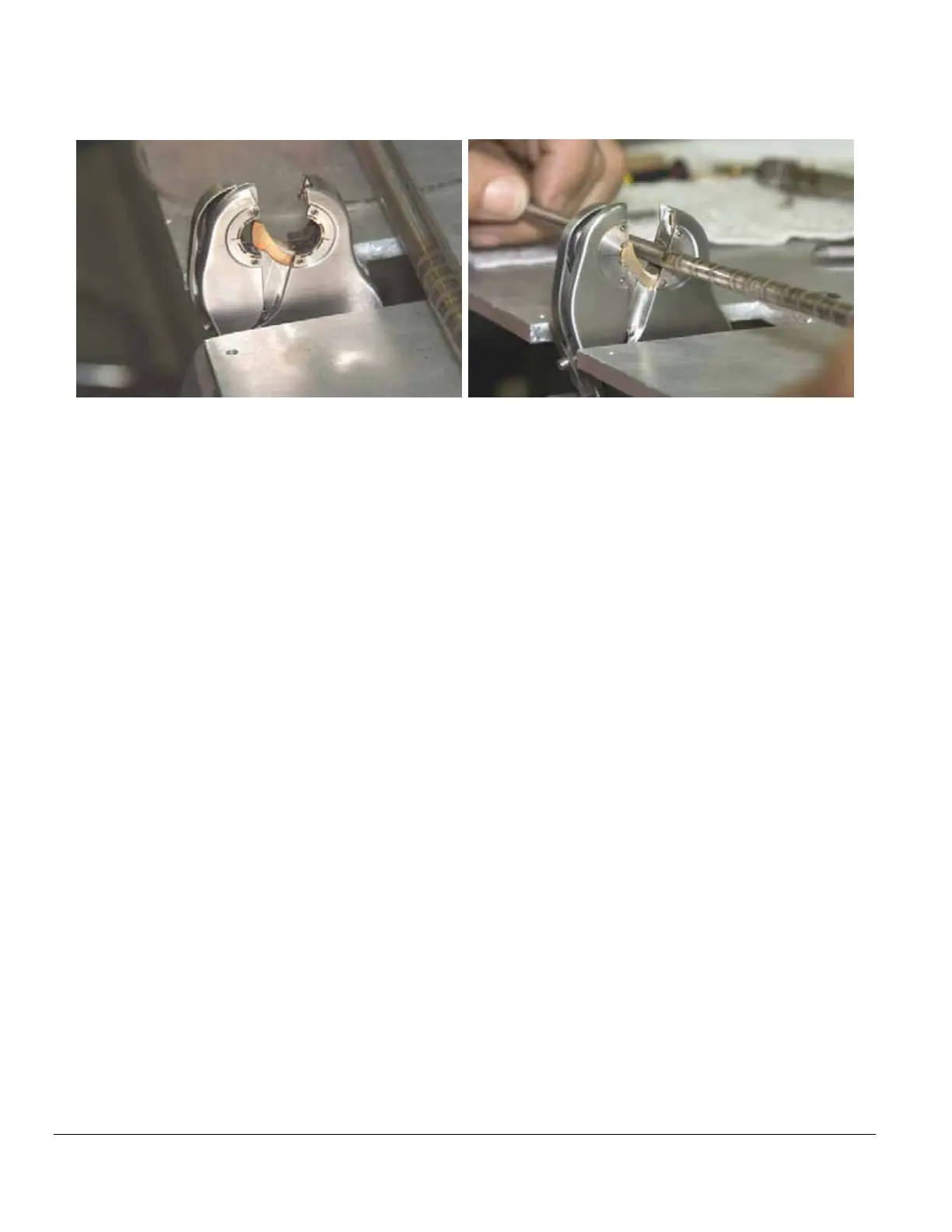

Image

above left, shows jaws open ready to receive sample tube to insure

collets are seated within the jaws.

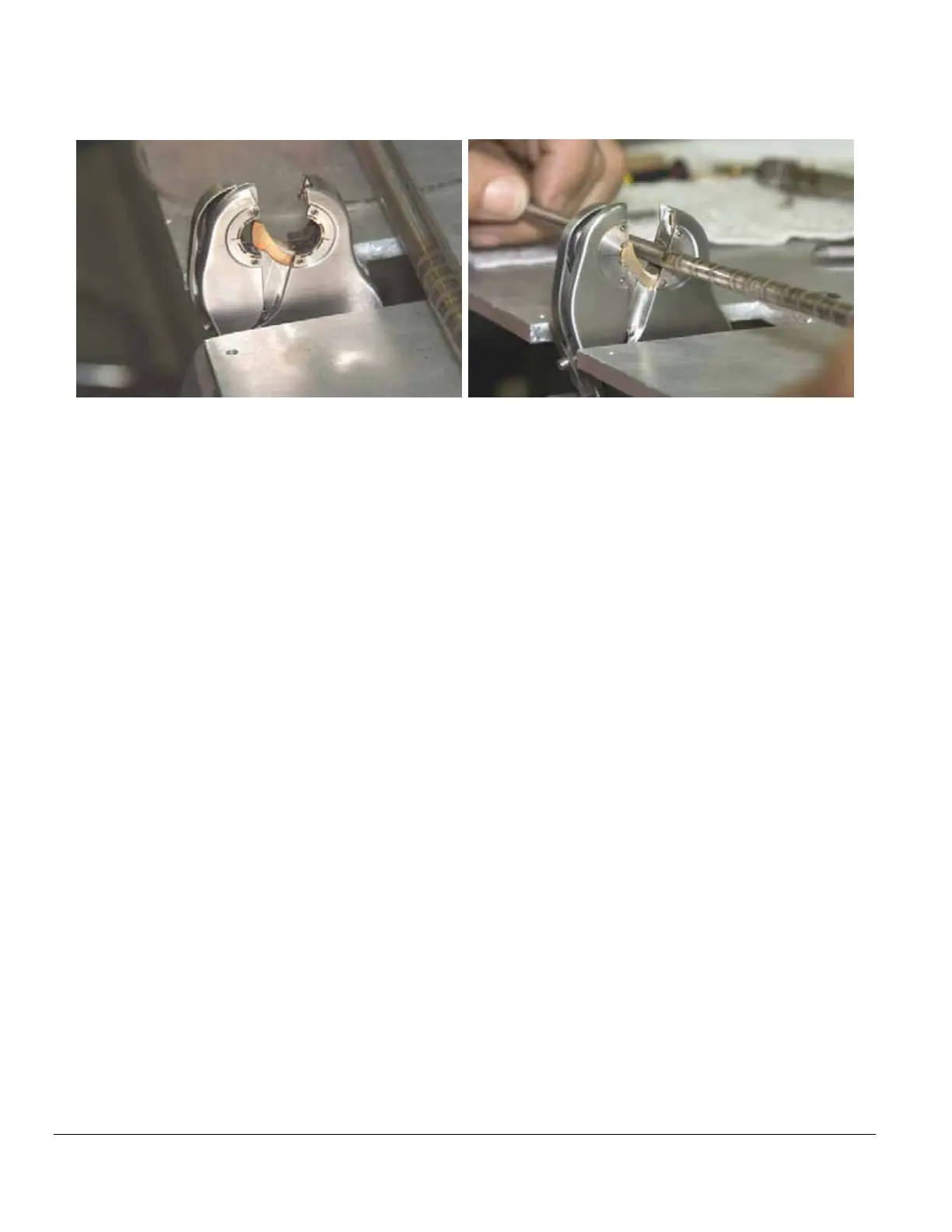

Image above right, shows tube being removed from jaws after verifying

collets are seated. SET ALIGNMENT can now be started.

4.4 OPERATION

OPERATION OPERATION

OPERATION PROCEDURE

PROCEDUREPROCEDURE

PROCEDURE

1. Insert first part into the right side. Micro fittings can be pressed against the back

right side of the jaw, parts that do not have a 0.250” tube stub must be aligned

with the electrode, either by lightly making contact with the center pin (when in F2

or B2 mode), or by visually aligning it with the electrode.

2. Depress the right foot pedal or press the cycle button on the weld head to clamp

right side.

3. Insert second part into the left side of the weld head lightly pressing it against the

first part.

4. Depress the right foot pedal or press the cycle button on the weld head to clamp

left side.

5. Verify that the number shown on the display is “03” or less. If greater than “03”,

depress the left pedal or abort button on the head and repeat steps 1 – 4 above.

6. Setup ID purge through tubes to be welded.

7. Depress the right foot pedal or press the cycle button on the weld head to begin

weld process.

8. After the weld is completed, in Field Mode, press cycle to open the jaws; in Bench

Mode, the jaws will automatically open.

9. Repeat procedure for next weld joint.

Loading...

Loading...