G

-3- -4-

07

08

09

10

10

+DC12V

Ue=

100%

K3

A1 A2

KM

M

1 L1

3 L2

5 L3

L1

L2

L3

380 V

50/60HZ

2T1

4T2

6T3

(MCCB)

(ELCB)

A2

B2

C2

(KM)

N

或

L1

K2

K1

FU

01

02

03

04

05

06

11

12

G

1

3

5

2

4

6

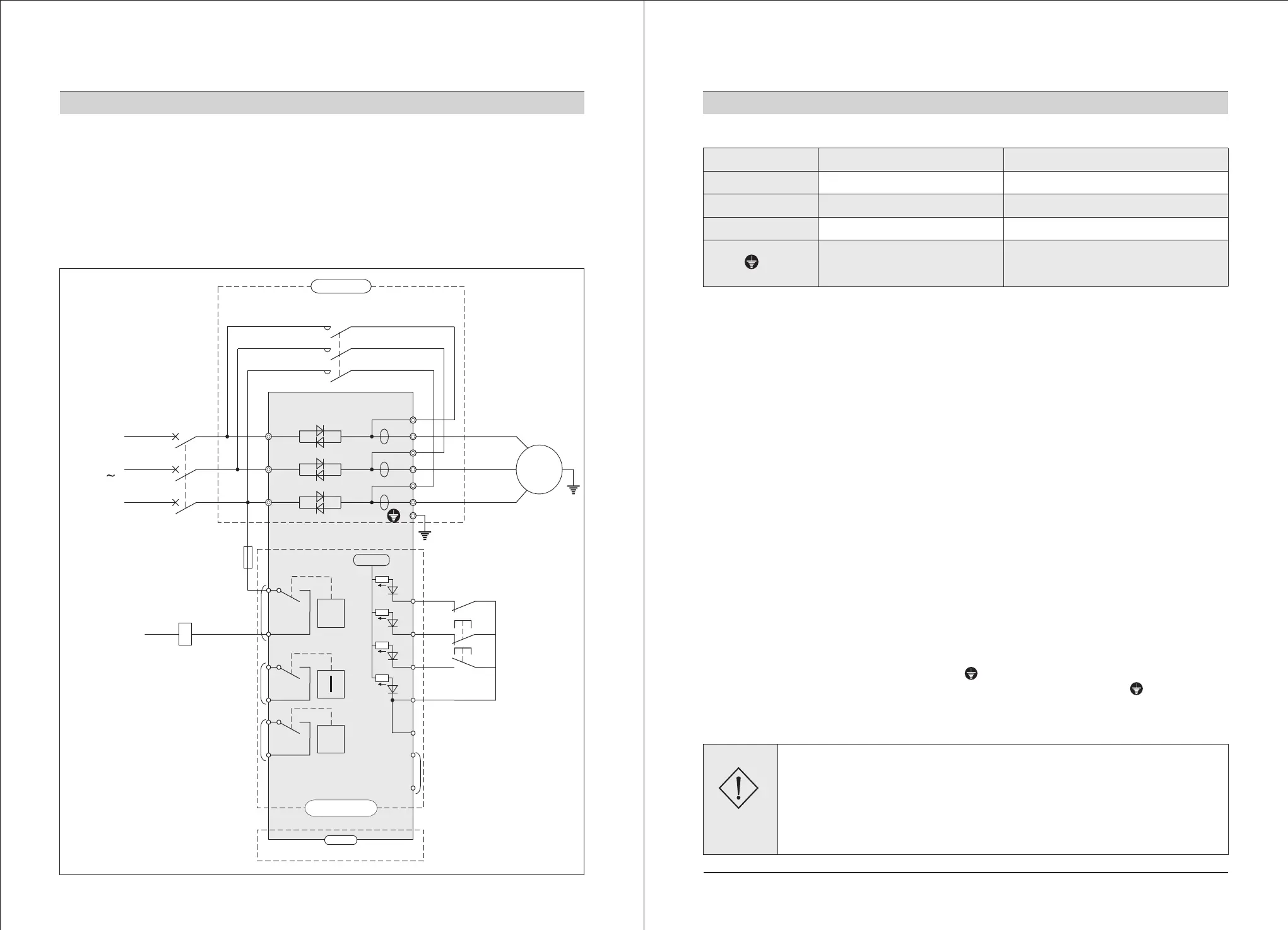

2. Installation and wiring

Please pay attention to the following points when wiring. Refer to diagram 2-3-1

for basic wiring

The power supply must be connected with terminals 1L1, 3L2 and 5L3 of main circuit, no phase

requirement. If there is any wrong connection, it will damage the soft starter.

The ground terminals must be earthed finely, so that it can avoid electric shock or fire accident,

and it can reduce the noise.

The two terminals of lead should be compressed joint to assure high reliability in connection.

2-3 Wiring

Diagram 2-3-1

Diagram of

basic wiring

Power

supply

3-phase

Equipped with

circuit breaker

Or

Leakage

circuit breaker

Full voltage

output

Time delay

output

(Programmable)

Fault output

Main circuit

Equipped with bypass electromagnetic contactor

Instantaneous stop

Stop

Start

Common port

Analog output

(DC 0-20mA)

Control circuit

RS485 communication

2. Installation and wiring

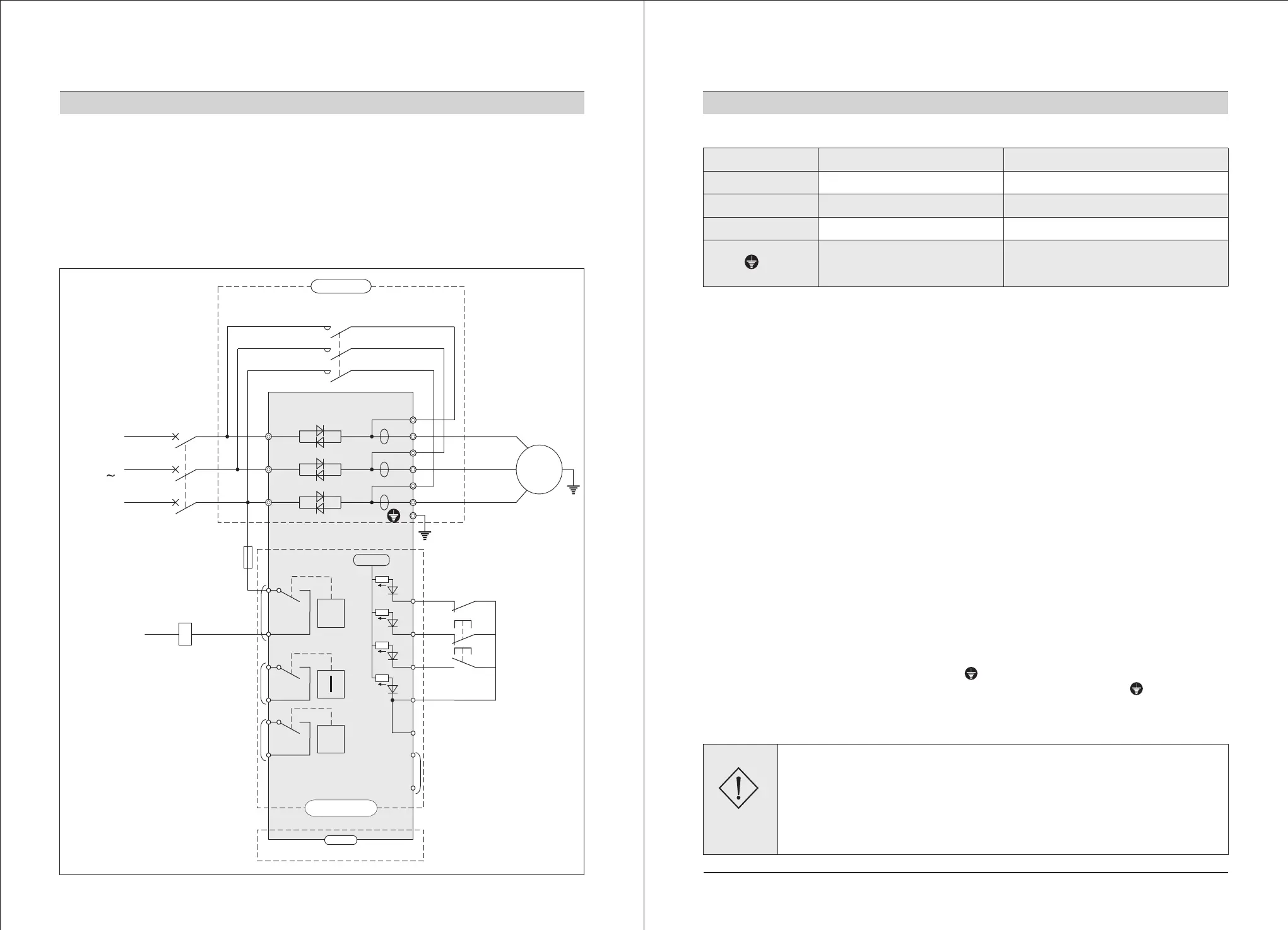

2-4 Wiring of main circuit and earth terminal

Table 2-4-1 Function of main circuit and earth terminal

(1) Power supply input terminals of the main circuit (1L1, 3L2, 5L3)

Power supply terminals 1L1, 3L2 and 5L3 of main circuit connect with 3-phase power supply

through protective circuit breaker or leakage circuit breaker. It is not necessary to consider the

connecting phase sequence.

Please do not adopt the ON/OFF control method (power supply of main circuit) to start or stop

the soft starter, you should electrify the soft starter first, and then make use of the control terminal

that on the soft starter or the RUN and STOP keys to run or stop the machine.

Please do not connect with single-phase power supply.

(2) Output terminals of soft starter (2T1, 4T2, 6T3)

Connect the output terminals of the soft starter with 3-phase motor in correct phase sequence.

If the rotation direction of the motor is wrong, you can exchange the connection of any two pha-

ses of 2T1, 4T2 and 6T3.

The output side of the soft starter can not be connected with capacitor and surge absorber.

When the wire between soft starter and motor is very long, the distributed capacitance among

the wire will produce high frequency current, it may cause phenomenon like over current and

trip, more leakage current, low accuracy of current display, etc. Therefore, we suggest that the

wire for motor connection should be less than 50m.

(3) Bypass connection (A2, B2, C2)

The bypass connection terminals A2, B2 and C2 must be connect with the electromagnetic by-

pass contactor, otherwise, the soft starter would be burned. After the soft starter is started, the

power device of major loop (silicon controlled rectifier) exits, meanwhile, the bypass electrom-

agnetic contactor works, and the motor runs normally, pay attention to the phases, they cannot be

wrong connected.

(4) Grounding terminal of soft starter ( G)

In order to reduce noise and for safety consideration, the grounding terminal G of the soft

starter must be firmly earthed. In order to avoid electric shock and fire accident, the metal enclo-

sure and frame of the electric equipment should comply with the national electric requirements.

Terminal mark

1L1, 3L2, 5L3

2T1, 4T2, 6T3

A2, B2, C2

Terminal name

Power supply input of main circuit

Output connection of soft starter

Bypass connection

Grounding terminal of soft

starter

Description

Connect with 3-phase power supply

Connect with 3-phase motor

Connect with bypass electromagnetic contactor

The grounding terminal of the case

of soft starter should be earthed firmly

Confirm that the input phase number and rated input voltage of the soft starter should be accord

with the phase number and voltage value of the AC power supply.

The AC power supply can not connect with the output terminals (2T1, 4T2, 6T3, A2, B2, C2)

The bypass electromagnetic contactor must be connected, and the phase sequence can be wrong

connected.

Otherwise, there may be accidents happen.

Danger

Loading...

Loading...