-11-

-12-

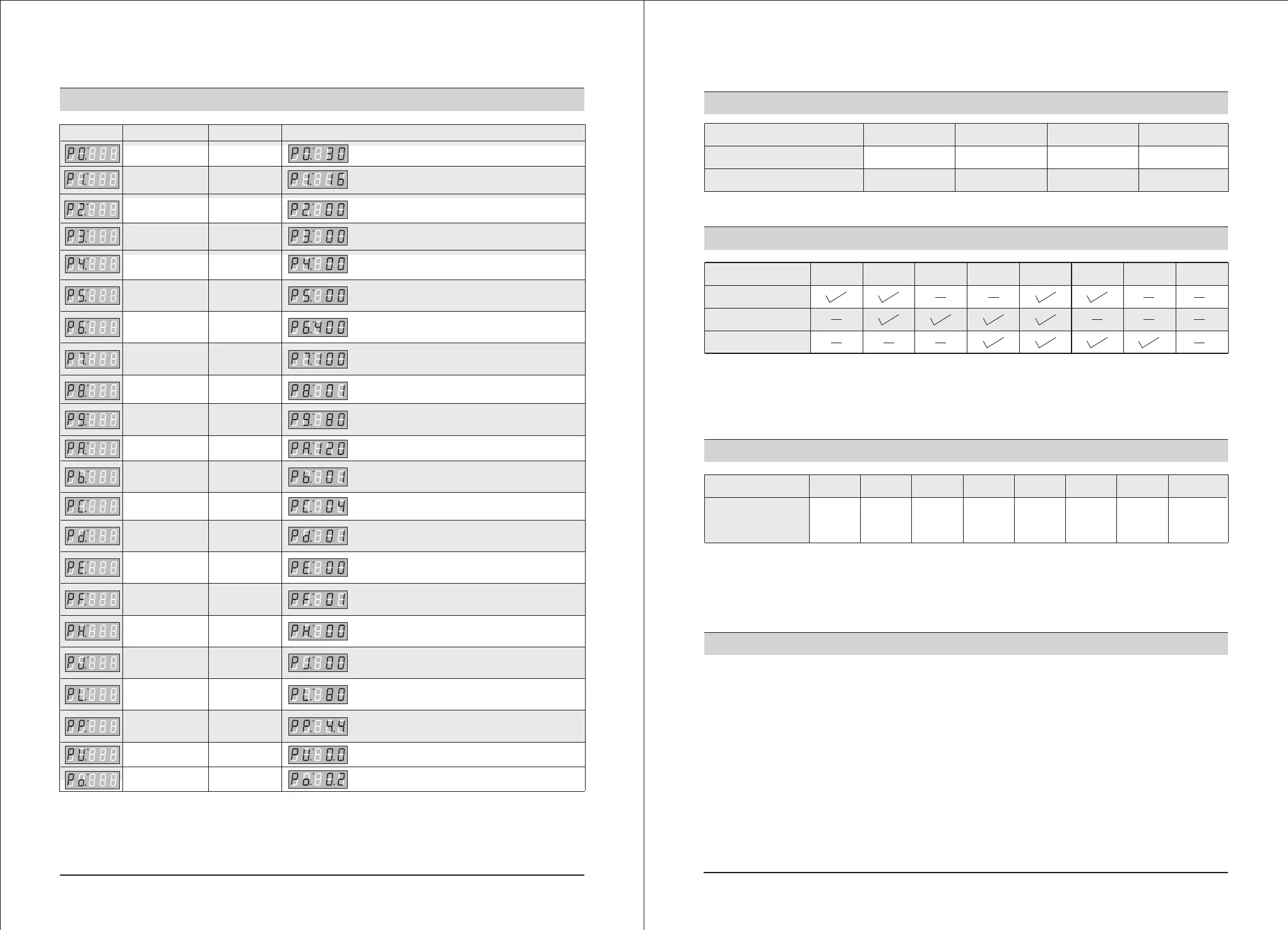

5-1 Function of code setting

5. Basic functions

30-70%

2-60S

0-60S

0-999S

0-999S

0-999S

50-500%

50-200%

00-03

40-99%

100-130%

00-06

00-04

00-07

00-09

00-03

00-64

00-07

20-100

Aircraft

Settings

Function code

Name of function

Setting range Factory value

Description

Starting voltage

Time of soft start

Time of soft stop

Time delay

starting

Time delay

programming

Time delay

interval

Current limiting

when starting

Max working

current

Display mode of

the keyboard

Under-voltage

protection

Over voltage

protection

Starting mode

Allowed output

protection

Operating control

mode

Allowed restart

Allowed parameter

modify

Communication

address

Programming

output

Current limiting

when soft stop

Motor rated

current

Effective under voltage ramp mode; when PB is set at 1,

it is modifiable, and set at 0, the starting voltage is 40%

Effective under voltage ramp mode; when code PB

is set 1, the modification is effective

Free parking is set to 0, 1 drag N should be set to 0

Press starting key (set the time), time delay starting

by count down, set at 0, it will start immediately

Output (03 and 04 terminals) of the relay, set at 0,

it will close immediately

Time delay when release from overheat, the

indication lamp flashes during the time delay

Effective under current limiting mode; when code

PB is set at 0, the modification is effective, and set

at 1, the max current limiting value 400%

The input mode of parameter P6 and P7 is

determined by P8

Refer to 6-1 in Page 12 for details

Protect when it is lower than the set value

Protect when it is higher than the ser value

00 current-limit; 01 voltage; 02 kick +current-limit;

03 kick +voltage; 04 current ramp; 05 double closed loop;

06 forbidden

00 primary; 01 light load; 02 standard;

03 heavy load; 04 senior

When set at 0, it is keyboard operation,

refer to 6-2 in Page 12 fore details

0: forbidden; 01-09: times of automatic restart

00: not allowed to modify the parameter;

01:allowed to modify the part of purameter;

02: allowed to modify the parameter

03: Allows modification bypass delay

Used for multi soft starters and upper machine for

multi-machine communication

Output setting (03 and 04 terminals) of relay,

refer to 6-4 in Page 12

Refer to description in P21

The soft start showing adaptation of the motor

rated current

Remark: 1. The max working current whose code is P7 means the max current for motor's conti-

nuous operation on the basis of PP setting value.

2. If you do not press the operating keys when under the setting state, then it will exit

the setting state automatically.

3. It is unable to set any parameter during soft start and soft stop, and you can set under

any other state.

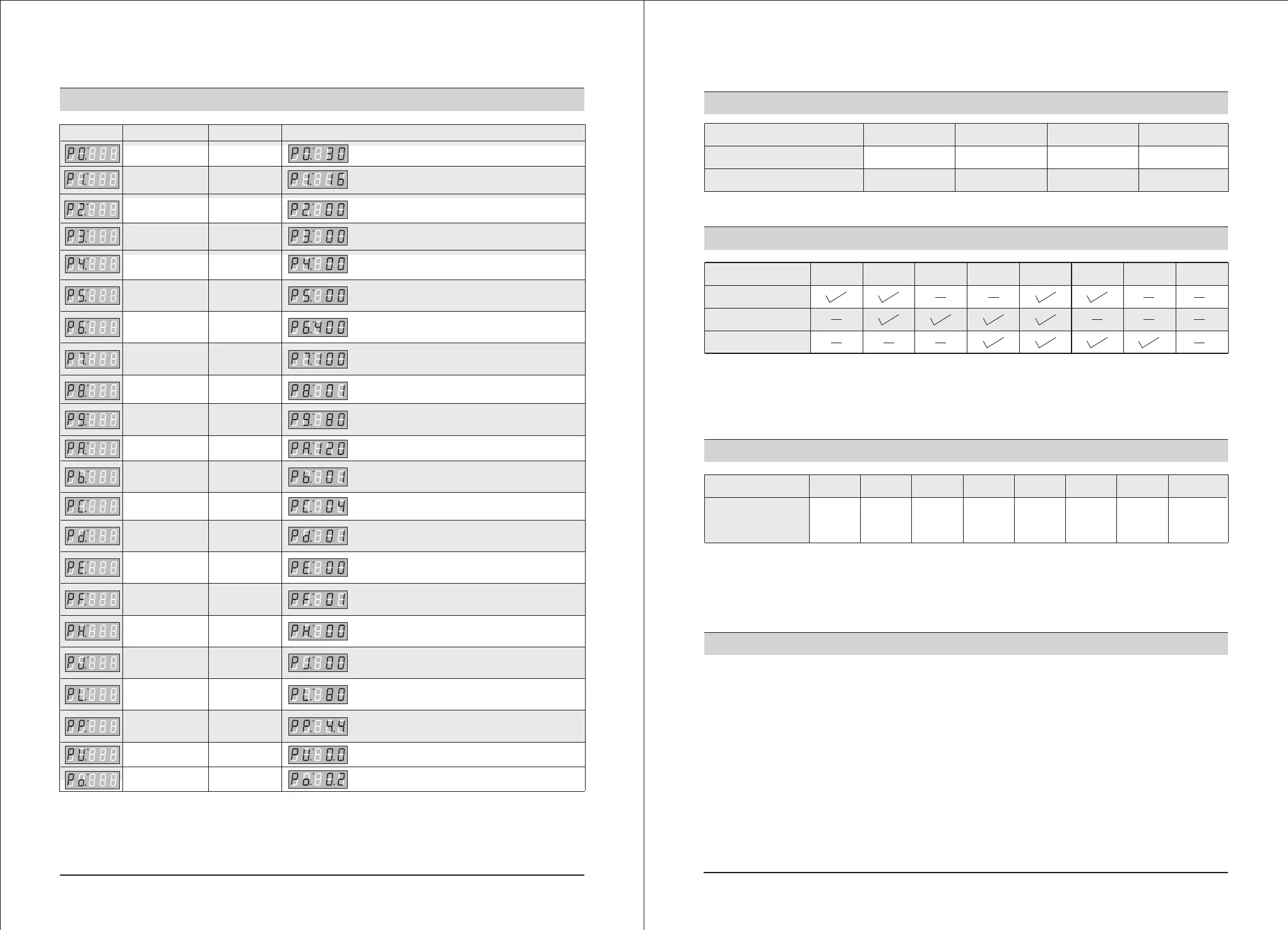

6. Instruction for function selection

6-1 Code P8 is used to choose input mode and display mode

0 1 2 3

The set value of code P8

Input mode of P6 and P7

Current value

Percent

Display mode

Current value

Percent

Current value Current value

Percent Percent

■When code P6 and P7 input by percent, it indicates the percent of current value of the motor set by code FP.

6-2 Code PD is used to choose control mode of the soft starter

0 1 2 3

4

5 6

7

Value of PD

Keyboard control

Terminal control

Communication

■ √ means can be chosen, and - means can not. If you want no unexpected stop after starting or no unex-

pected starting during maintenance, then you can set the PD at 7, and it will forbid any starting or stop ope-

ration.

■ When it is allowed external control, please connect with a NC button switch or short circuit between the

external control terminals 08 and 10, so that when it is open circuit, it can not start the motor.

6-3 PJ is used to set the operating time of output relay

0

1 2

3 4 5 6

7

Value of PJ

Operating time

of output relay

When send

the starting

order

When

starting

When

bypass

running

When

stop

When

finished

stopping

When

instantaneous

stop

When

there

is fault

When the

auto restart

is finished

■ When the P4 is not 0, then take the above time as starting point and begins time delay according to set

time of P4. When time delay finishes, it acts, when P4 is 0, it will act immediately.

■ The output reset time (namely contact break) that is after P4 set time finishing delay, then retain 1s; if

start motor again, it breaks off last programming automatically, while, starting the cause. It can program

the relay output function flexibly, shorten the external control logic circuit efficiently.

6-4 Instruction for code PU motor underload protect

■ PU<10,prohibit motor under-voltage protection function, underload protection current scope is the

motor rated current of 10%~90%,be determined by the tens digit at PU. Underload protect delay for the

range of 5 to 90seconds,by setting the PU setup times 10 to determine, when PU units digit is 0,the protect

action delay for 20 seconds.

■ This series soft starter protected mode set the default for the “senior” at PC, if the customers require to

drive light load (such as light bulbs) debugging, need to modify protected mode “primary” at PC,

otherwise soft starter alarm.

00-99%

00-11

Motor underload

protection

Bypass Delay

Refer to 6-4 in Page 12 for details

When PF is 03 Visible

Loading...

Loading...