12

TX Second Stage Regulator Maintenance Manual

13

TX Second Stage Regulator Maintenance Manual

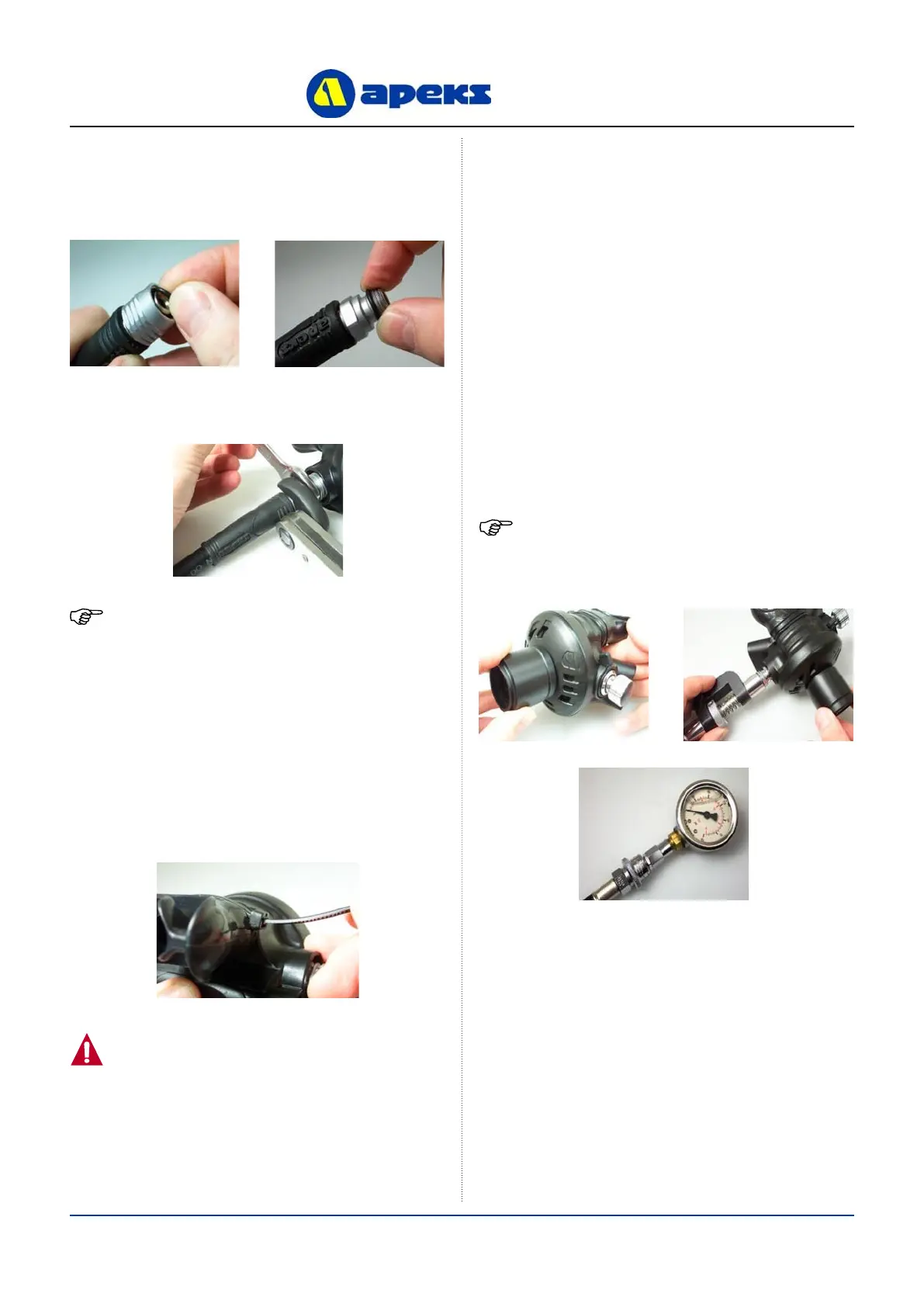

FINAL TESTING

Setting the Lever Height

1. Connect the rst stage regulator to a calibrated test bench and

pressurise the system to 200 bar (±10) or 2900 psi (±145).

Connect an intermediate pressure gauge to the rst stage

regulator and ensure that the I.P. is set to 9.5 bar (±0.5) or

137 psi (±7.2). Make sure that the Adjuster Knob (28) is fully

wound out and that the Venturi Lever (14) is set to the “+”

position.

2. Tap the purge button quickly, this will cause the

regulator to freeow. Stop the freeow after a couple of

seconds by placing a hand over the mouthpiece.

3. Place the NO Gas Flow end of the TX Setting Tool (AT69

for all models except the TX100 or AT70 for the TX100)

onto the purge button decal (1). Depress the Purge button

by pushing the tool towards the 2nd stage until it stops

against the Front cover. If no gas ows from the second stage

proceed to step 5. If gas ows from the valve follow step 4.

4. Disconnect the second stage from the hose as shown in

step 1 of the disassembly procedure. Using the Slotted Seat

Adjuster Tool (PN AT51) , turn the seat (17) clockwise by

approximately 1/16 of a turn. Repeat step 3.

5. Place the Gas Flow end of the TX Setting Tool onto the purge

button decal (1). Depress the Purge button by pushing the

tool towards the 2nd stage until it stops against the Front

cover. If gas ows from the second stage the lever height has

been set correctly. If no gas ows from the valve proceed to

step 6.

6. Disconnect the second stage from the hose as shown in

step 1 of the disassembly procedure Using the Slotted Seat

Adjuster Tool (PN AT51) , turn the seat (17) anti-clockwise

by approximately 1/16 of a turn. Repeat both step 3 and step

5.

(Testing is continued on the next page)

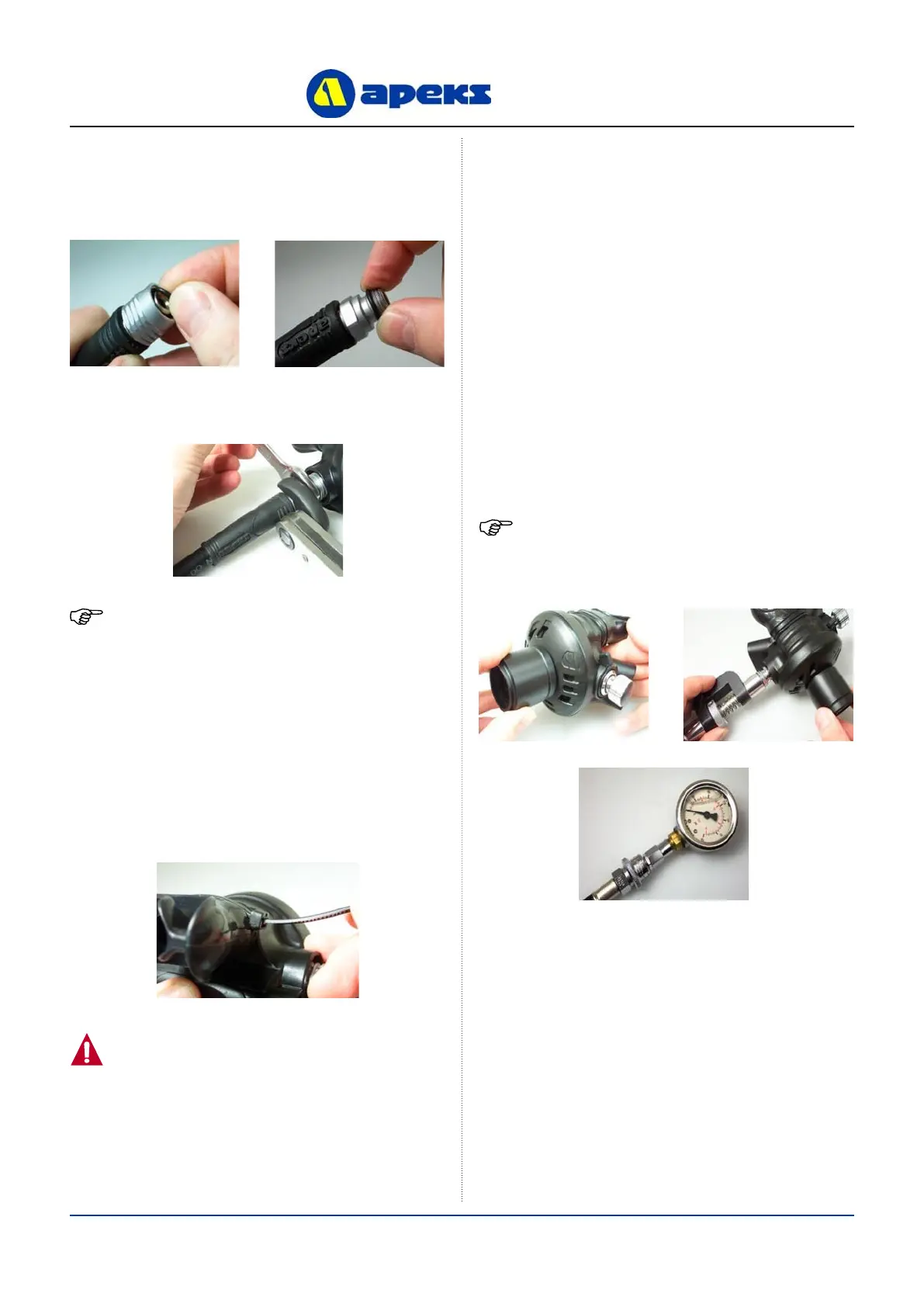

Fitting Hose and Mouthpiece

WARNING: Ensure that the Mouthpiece is

properly secured on the outlet port.

NOTE: If your facility is equipped with a test bench,

perform the tests before installing the mouthpiece.

General instructions for performing bench tests are

located in the next section, “Final Testing.”

19. Screw the Hose onto the second stage. Using an 11/16”

crows-foot on a torque wrench and a spanner on the Heat

Exchanger, tighten the Hose to 5 Nm (3.7 lbf/ft).

18. Add a new ‘O’ ring to the male end of the Hose. Install a

new, lubricated ‘O’ ring into the swivel end of the Hose.

20. If equipped with a comfo-bite Mouthpiece, make sure the

‘bridge’of the Mouthpiece (12) is facing upward. Stretch

the Mouthpiece over the second-stage Mouthpiece outlet

port. At the base of the Mouthpiece is a groove for the

Mouthpiece Clip (11). Wrap the Clip around the Mouthpiece

so that the buckle points toward the Hose. Tighten the Clip

and snip the excess with side cutters.

NOTE: An inline adjuster can be used can be used as

shown below. This allows the seat (17) to be adjusted

without having to disconnect the second stage from the

hose.

Loading...

Loading...