10

XTX FSR & FST First Stage Regulator Maintenance Manual

Adjusting the First Stage

CAUTION: If the pressure gauge rapidly exceeds

11 bar, then there is a HP leak. Quickly close the

cylinder valve and purge the regulator. Refer to

the troubleshooting table for the causes of the

leak.

WARNING: Compressed air can be highly

explosive and is dangerous if misused. Ensure

cylinder valve is opened slowly. Use Eye and

Ear Personal Protective Equipment when

performing any tests involving Compressed

air.

Final Assembly

NOTE: The Pour Moulded Hydrostatic Diaphragm

(2) in the XTX does not need to be replaced with a

new one unless it is deemed damaged or worn by the

technician.

1. Attach the rst stage

(with no Blanking

Plugs tted) to a fully

charged 232 or 300

bar cylinder. Slowly

open the cylinder

valve, this will

remove any particles

or contaminants from

the rst stage.

2. Install new

lubricated ‘O’ Rings

(12,27) on all of

the Blanking Plugs

(26,28). Using a

5mm Allen key,

install all of the

Blanking Plugs into

the Valve Body.

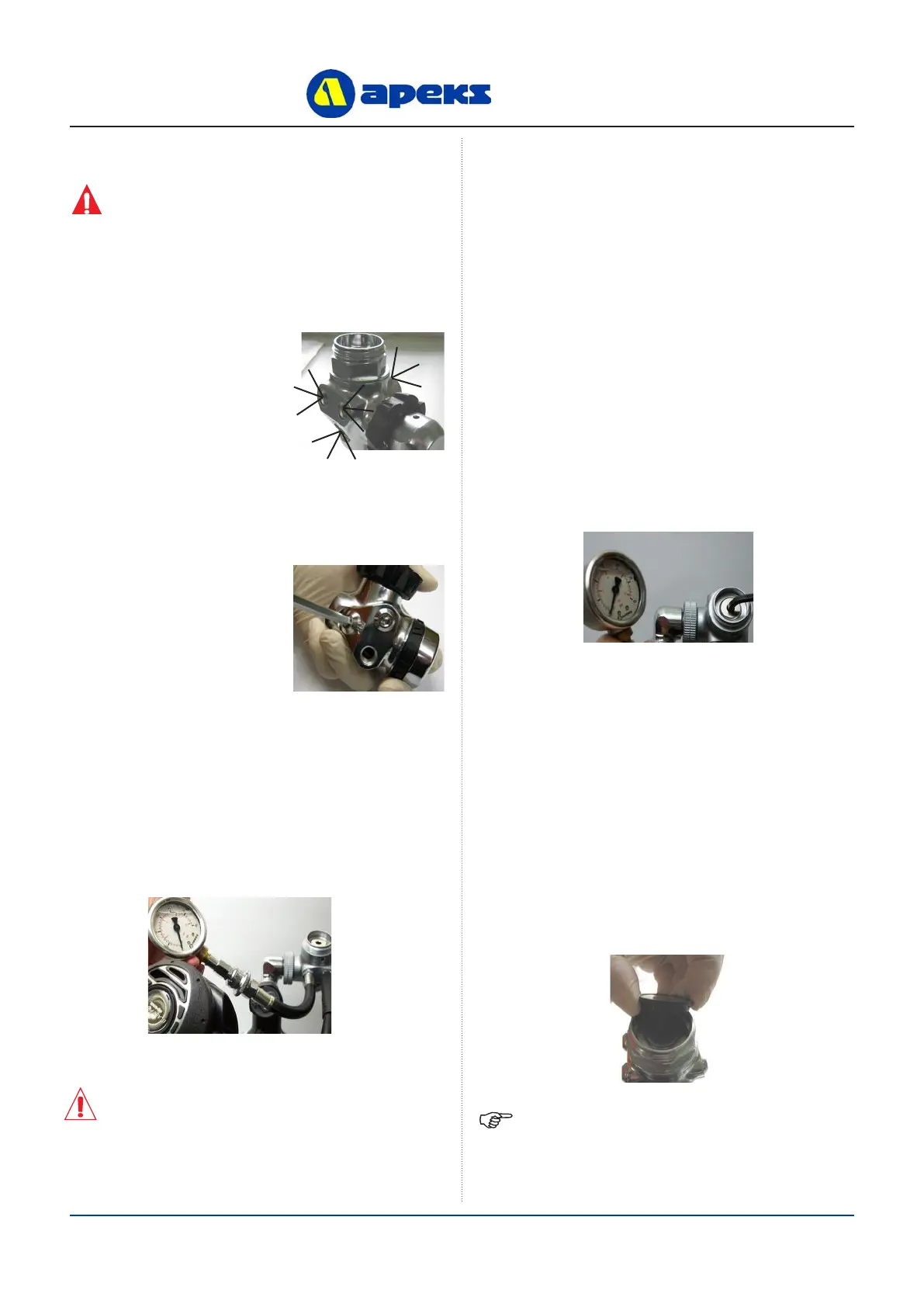

3. Attach a MP test gauge (0 - 20 bar) to a medium

pressure hose and thread the hose into a MP port.

If your test gauge does not have an over pressure

relief valve, you must also attach a properly adjusted

second stage to the rst stage to act as the relief valve

in case of a HP leak. Make sure Blanking Plugs are

installed in any open ports.

4. Assuming there are no leaks, close the cylinder valve

and depressurise the regulator by opening the gauge

relief valve or by pressing the purge button of the

second stage regulator. Adjust the medium pressure

by turning the Spring Adjuster (4): Turning in the

Spring Adjuster increases the MP; Turning out the

Spring Adjuster decreases the MP. Turn the Spring

Adjuster in 1/8th turn increments and purge the relief

valve several times after each adjustment. When the

MP is between 9 and 10 bar , purge the relief valve

on and off 10-15 times. After cycling, watch the gauge

needle. The rst stage MP should “lock-up” between 9

and 10 bar. Make any adjustments as necessary. Allow

the rst stage to stay pressurised for several minutes

and check the MP again to make sure it remains

“locked-up” between 9 and 10 bar. If the MP creeps

upward more than 0.25 bar, then there is a leak. Refer

to the troubleshooting table for possible causes.

5. Close the cylinder valve and depressurise the

regulator by opening the gauge relief valve or by

pressing the purge button of the second stage

regulator. Close the relief valve and repressurise

the system. The MP should still read between 9 and

10 bar. If the pressure reading is different than the

original setting, repeat steps 3 and 4 until the MP is

stable.

1. With the regulator still pressurised, insert the Load

Transmitter (3) into the Diaphragm Clamp (6). Press a

new Hydrostatic Diaphragm (2) into the Environmental

End Cap (1) (If required).

Loading...

Loading...