6

XTX Second Stage Regulator Maintenance Manual

Pinch Method

Press upwards

on sides of ‘O’

Ring to create a

protrusion. Grab

‘O’ Ring or insert

‘O’ Ring tool at

protrusion.

NOTE: Ensure that the tool is rmly pressed

against the Case Cover whilst unscrewing.

Removal of hose

Removal of diaphragm

GENERAL CONVENTIONS

Unless otherwise instructed, the following terminology and

techniques are assumed:

1. When instructed to remove, unscrew, or loosen a

threaded part, turn the part anti-clockwise.

2. When instructed to install, screw in, or tighten a

threaded part, turn the part clockwise.

3. When instructed to remove an ‘O’ Ring, use the pinch

method (see gure below) if possible, or use a brass,

aluminium or plastic ‘O’ Ring removal tool. Avoid using

hardened steel picks, as they may damage ‘O’ Ring

sealing surfaces. All ‘O’ Rings that are removed are

discarded and replaced with brand new ‘O’ Rings.

4. The following acronyms are used throughout the

manual: MP is Medium Pressure; HP is High Pressure;

PN is Part Number.

5. Numbers in parentheses reference the key numbers

on the exploded parts schematics. For example, in the

statement, “...remove ‘O’ Ring (11) from...”, the number

11 is the key number to the Blanking Piece ‘O’ Ring.

DISASSEMBLY PROCEDURES

NOTE: Before performing any disassembly,

refer to the exploded parts drawing, which refer-

ences all mandatory replacement parts. These

parts should be replaced with new, and must not

be reused under any circumstances - regardless

of the age of the regulator or how much use it

has received since it was last serviced.

CAUTION: Use only a plastic, brass or

aluminium ‘O’ Ring removal tool (PN AT79)

when removing ‘O’ Rings to prevent damage

to the sealing surface. Even a small scratch

across an ‘O’ Ring sealing surface could

result in leakage. Once an ‘O’ Ring sealing

surface has been damaged, the part must

be replaced with new. DO NOT use a dental

pick, or any other steel instrument.

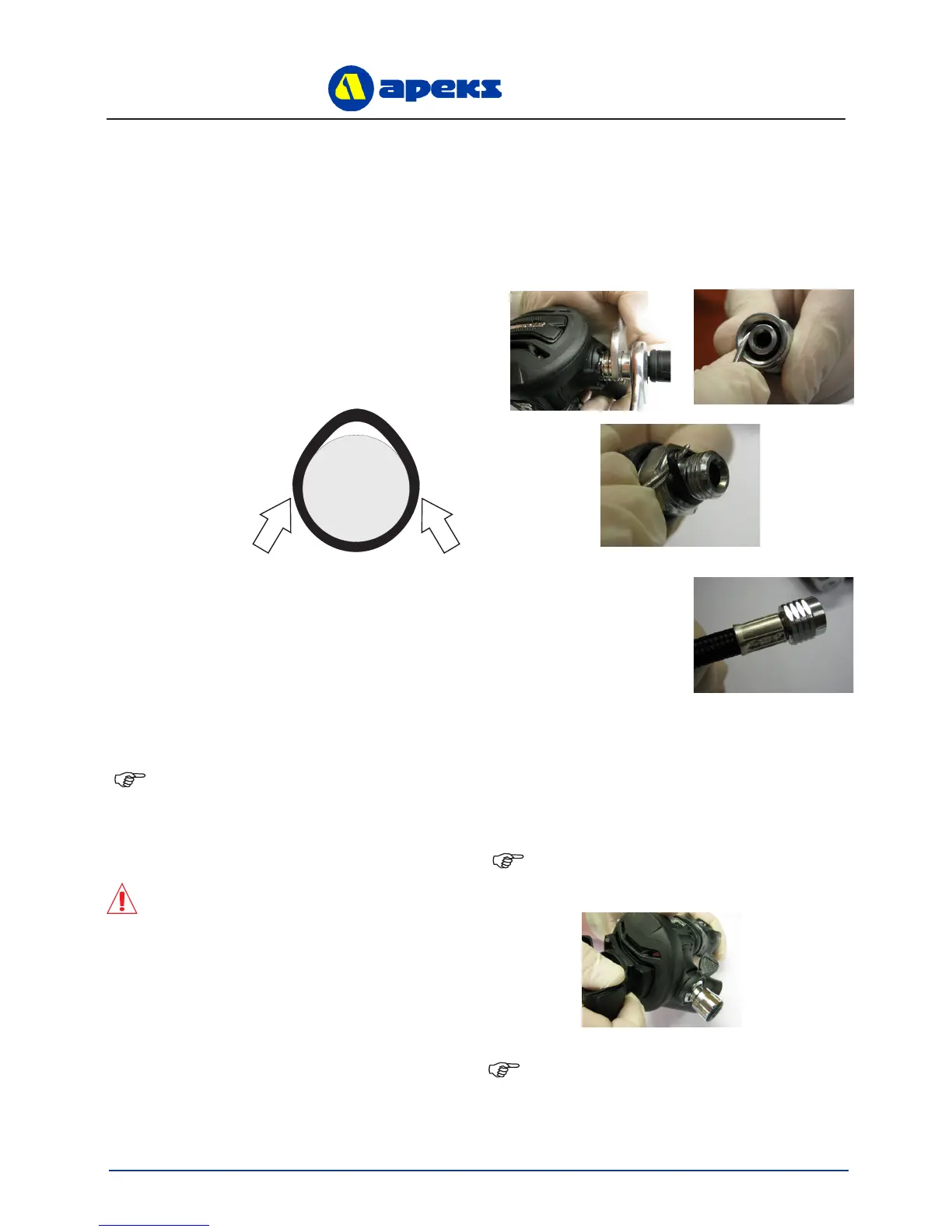

1. Using two 11/16” spanners, hold the Heat Exchanger

(6) stationary while turning the Hose Swivel anticlockwise.

Remove the ‘O’ Ring from inside the Hose

Swivel. Exercise caution not to scratch the ‘O’ Ring

groove. Remove the ‘O’ Ring from the male end of the

Hose.

2. Pull back the two

Hose Protectors and

inspect the Hose

Crimps. If either

Crimp is damaged or

the Hose is pulling

out of the crimp then

the Hose must be

replaced.

3. Using the Apeks XTX Tool (PN AT20F), unscrew the

Case Cover (2).

NOTE: The Front Cover (2) and Purge Button (1)

should be cleaned complete. It is not necessary to

remove the purge button when servicing.

Loading...

Loading...