15

G1SINGLE OPERATION MANUAL

© 2023 APPION INC. - ALL RIGHTS RESERVED

Helpful Hints (continued)

of the entire system charge as liquid - this means it should go very quickly for most of the recovery process (in

most larger systems, this could be over 90% of the refrigerant charge).

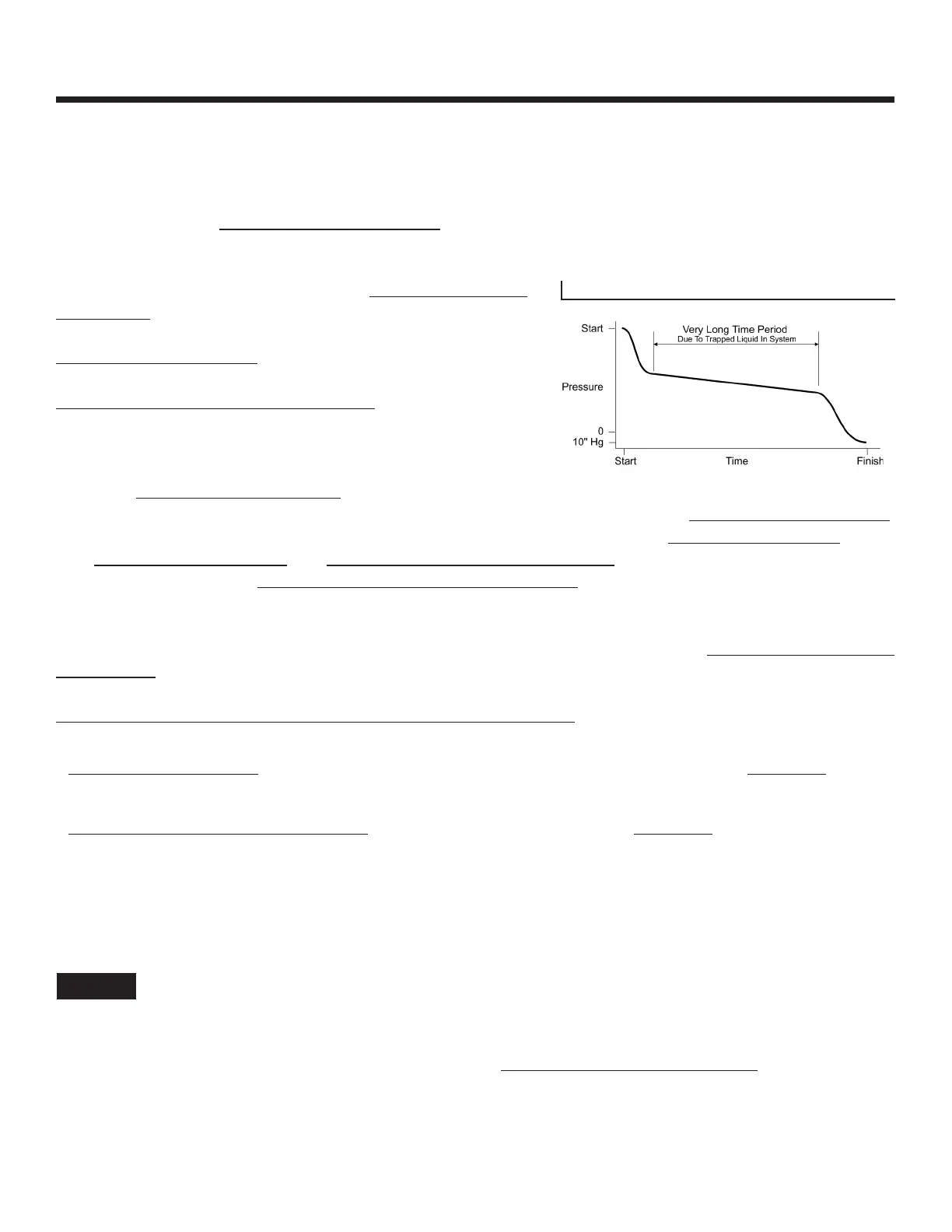

However, if you observe hot recovery cylinders, or very slow recovery aer only moving a few pounds of

refrigerant, then you likely have input restrictions. You may further confirm input restrictions by checking for

frost or condensation at each hose/port connection between the AC/R System and the recovery machine

(e.g., the system access port, or the inlet fitting to the recovery

machine). Input restrictions can cause liquid refrigerant to

get trapped behind the restriction, causing recovery to be

slower than the expected vapor rate (see Diagram 8), and

unexpectedly adding heat to the recovery cylinder.

What Happens With Input Restrictions:

Input restrictions will greatly slow down refrigerant recovery

by preventing the full “liquid flow” from reaching the recovery

machine. The pressure drop caused by the recovery machine

triggers a liquid-to-vapor expansion at the point of restriction, which drops the temperature of the liquid

refrigerant at the restriction. As the point of restriction continues to get colder, the vapor pressure drops,

slowing the vapor flow. Pretty soon, the recovery machine is only receiving a reduced flow of vapor that is

now picking up ambient heat and adding it to the heat of compression. All of this heat is sent along to the

recovery cylinder, quickly raising the recovery cylinder temperature.

Eorts to cool a cylinder are more eective when there is liquid refrigerant, as the liquid aids in transferring

heat through the cylinder walls to the “bucket of ice” or cooled airflow. However, if contents of the tank are

mostly vapor, eorts to cool the tank (e.g., airflow, ice) could be less eective than expected.

Remove Input Restrictions to Maximize Recovery Performance:

For the fastest recovery times, take the time to address these typical input restrictions before you start:

• Remove core depressors from all of the hose fittings (they block up to 50% of the flow) - See Tip #4

• DO NOT USE refrigerant charging hoses with “quick disconnect” or “auto-shuto” fittings

• Remove “Schrader”-type access valves using a Valve Core Removal Tool - See Tip #4

• Discard of used/worn hoses with deteriorating inner linings

With a full flow of liquid refrigerant, the G1Single will quickly fill the recovery cylinder with cool liquid. Once

the liquid recovery is complete, the remaining vapor will be pumped into a cooler tank, resulting in lower final

temperatures and faster overall recovery speeds.

Diagram 8

External Cooling Accessories Between Recovery Unit & CylinderTIP #3

Recovering large amounts of vapor (especially on a hot day) can increase the temperature of a recovery

cylinder, and the resulting increased back-pressure can further slow the vapor recovery process. In situations

like these, cooling the recovery cylinder and/or using an External Cooling Accessory (ECA) in a bucket of ice

water can cool o the tank and speed up the recovery process. For maximum recovery speeds, pre-cool the

recovery cylinder (and/or the ECA) by placing it in a bucket of ice water at least 30 minutes prior to beginning

the recovery process. The longer the cylinder is cooled, the better.

Loading...

Loading...