ENGINE

RSV mille

3 -90

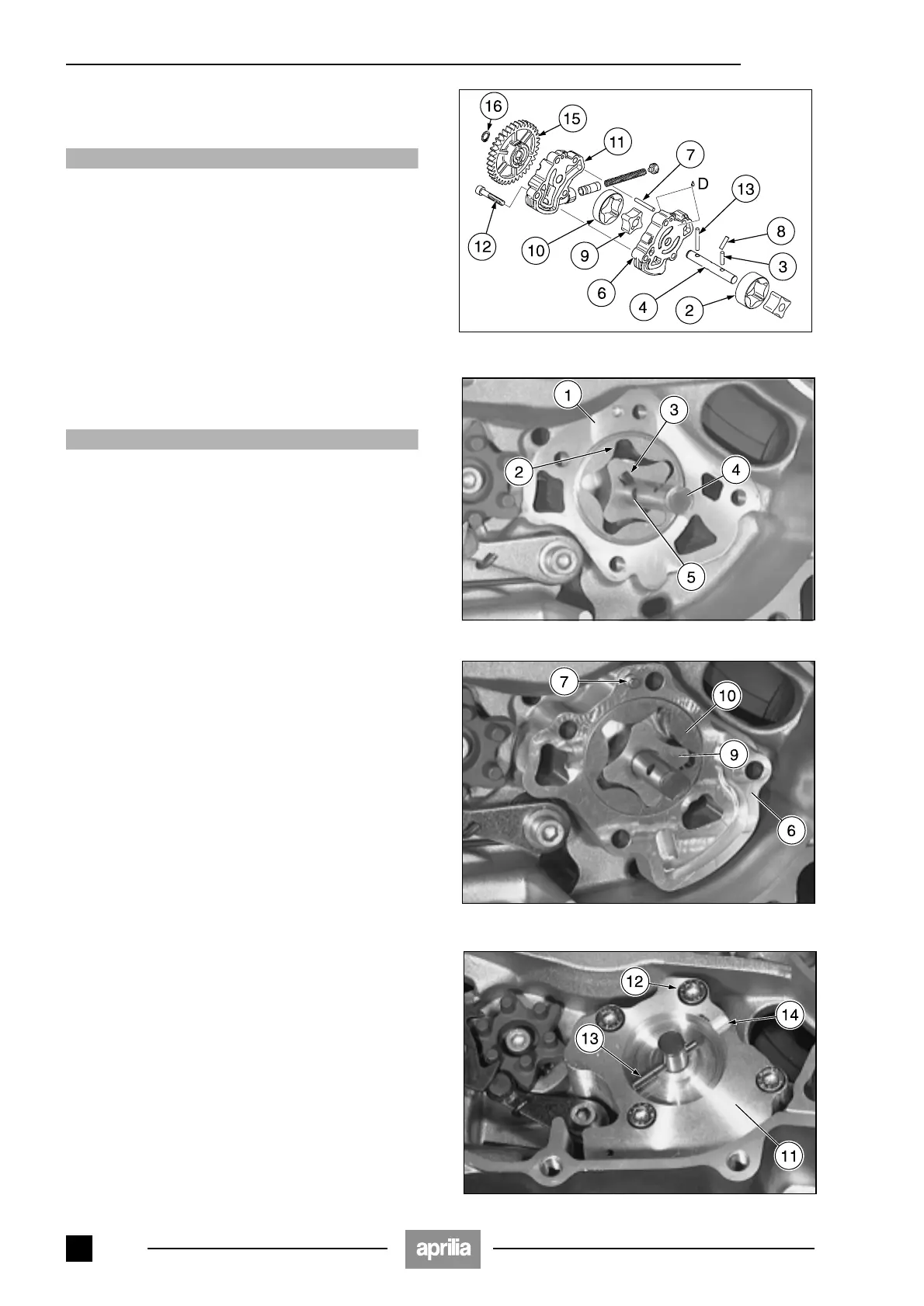

3.7.6 ASSEMBLING THE OIL PUMP

Carefully read 0.2.1 (PRECAUTIONS AND GENERAL

INFORMATIONS).

Make sure the LOCTITE

®

product does not get inside

the suction pump hole.

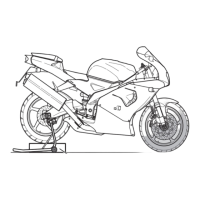

◆ Apply a thin film of LOCTITE

®

574 on the gasket sur-

face (1) of the oil pump casing.

◆ Insert the duly oiled external rotor (2) in the slot in the

casing.

NOTE The reference point must face down (towards

the engine casing).

◆ Insert the pin (3) in the last hole at the bottom of the oil

pump shaft (4).

◆ Insert the internal rotor (5) in the oil pump shaft (4), with

the housing slot facing up.

◆ Insert the oil pump shaft (4) in the casing, complete with

internal rotor.

Make sure the LOCTITE

®

product does not get inside

the pressure pump hole.

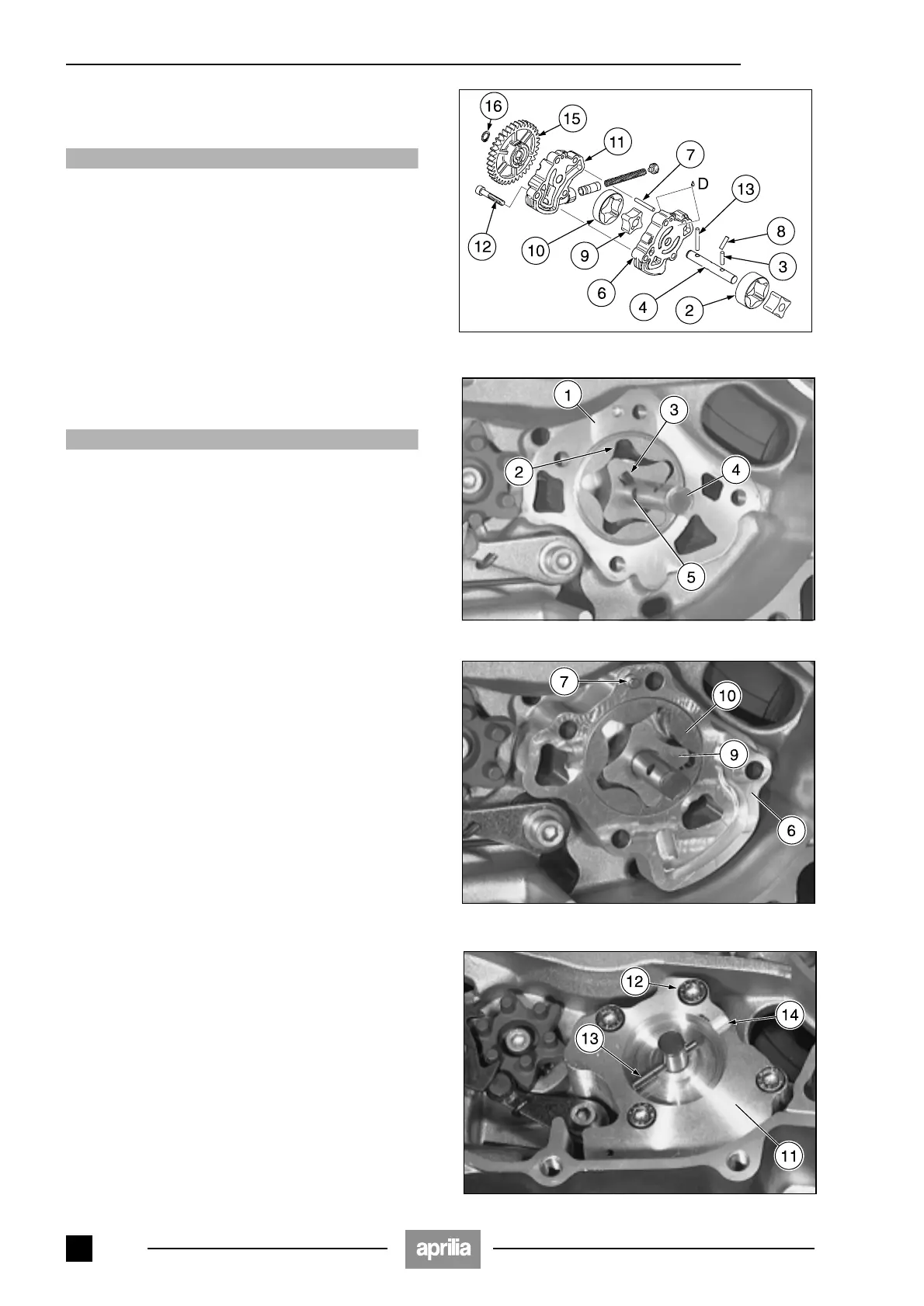

◆ Apply a thin film of LOCTITE

®

574 on the external gas-

ket surface of the oil pump casing (6) and install it on

the oil pump shaft (4).

◆ Fasten the oil pump casing (6), complete with pin (7),

inside the casing.

◆ Insert the pin (8) in the central hole of the oil pump

shaft.

◆ Insert the duly oiled internal rotor (9) of the pressure

pump on the oil pump shaft, with the driving groove fac-

ing down.

◆ Insert the duly oiled external rotor (10) in the oil pump

casing.

◆ Fasten the oil pump cover (11) with the four T.C.E.I.

screws (12).

Driving torque of screws (12): 11 Nm (1.1 kgm).

◆ Insert the pin (13) in the hole of the oil pump shaft.

NOTE The oil pump cover features a groove (14) ena-

bling the pin to be fitted.

Line the pin up with the centre of the oil pump shaft.

D = LOCTITE

®

574.

Loading...

Loading...