Service Manual Core 1

st

stage

Service Manual Core 1

st

stage

Rev. 05/2015 6

DISASSEMBLY PROCEDURE

1. Unscrew the hose from the first stage using a 9/16”

spanner.

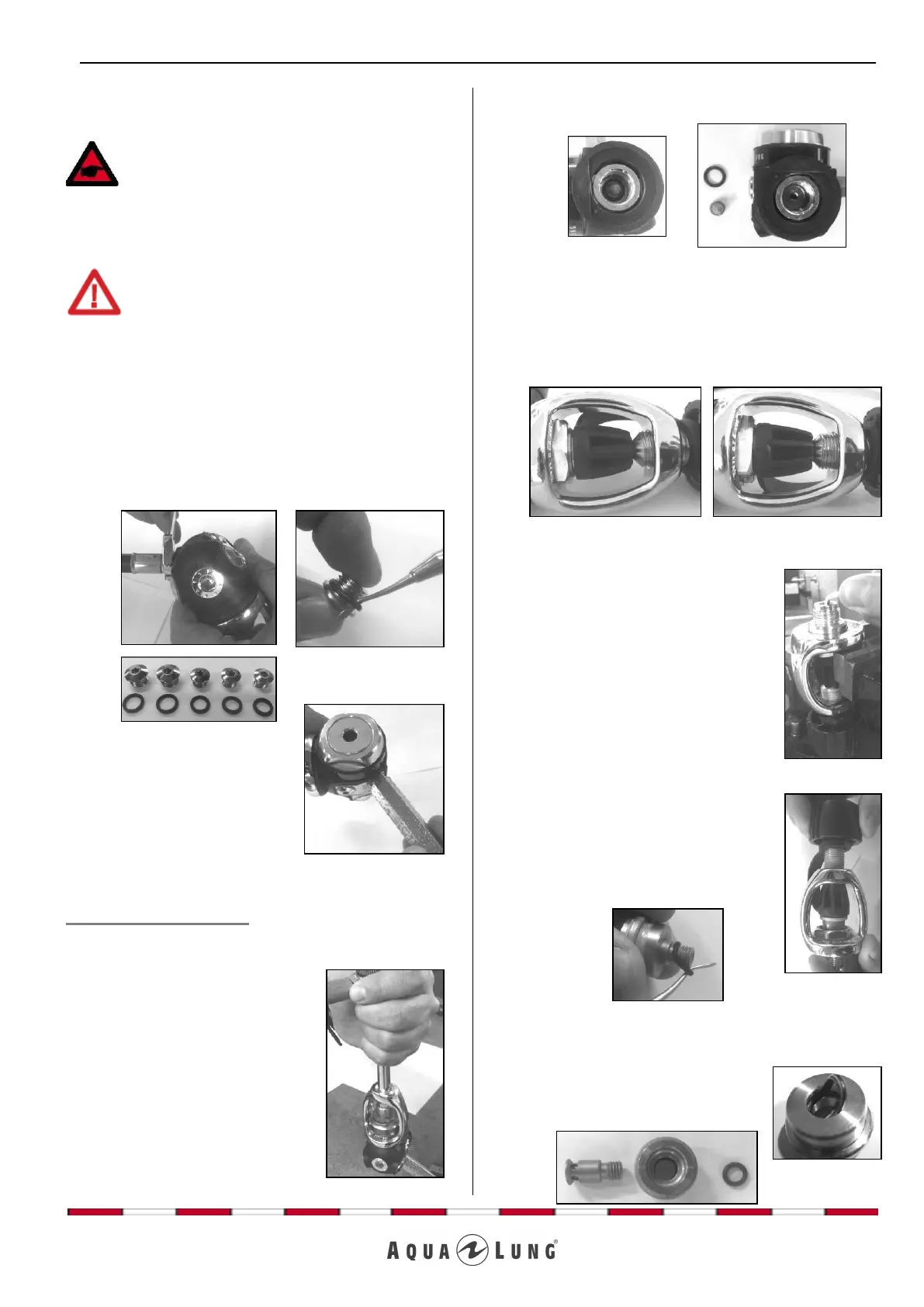

Unscrew MP plugs (122233) and HP plugs (122237)

with a 4mm Allen key. Remove the O-rings (124701

and 124703) with the tool (506001).

Screw the holding tool

(116320) into a free MP port.

YOKE CONNECTION

Start after point 1

2. Remove the yoke screw

(128631) and the dust cap

(124555).

Securely clamp holding tool

(116230) into vice with yoke

connection facing up. Place the

socket (A11001) on the yoke

retainer (129242) and unscrew

it. Remove the yoke retainer and

the yoke (124611) from the

body.

Remove the regulator from the

vice.

3. Remove the filter (129209) and the O-ring (124703)

from the body (129254).

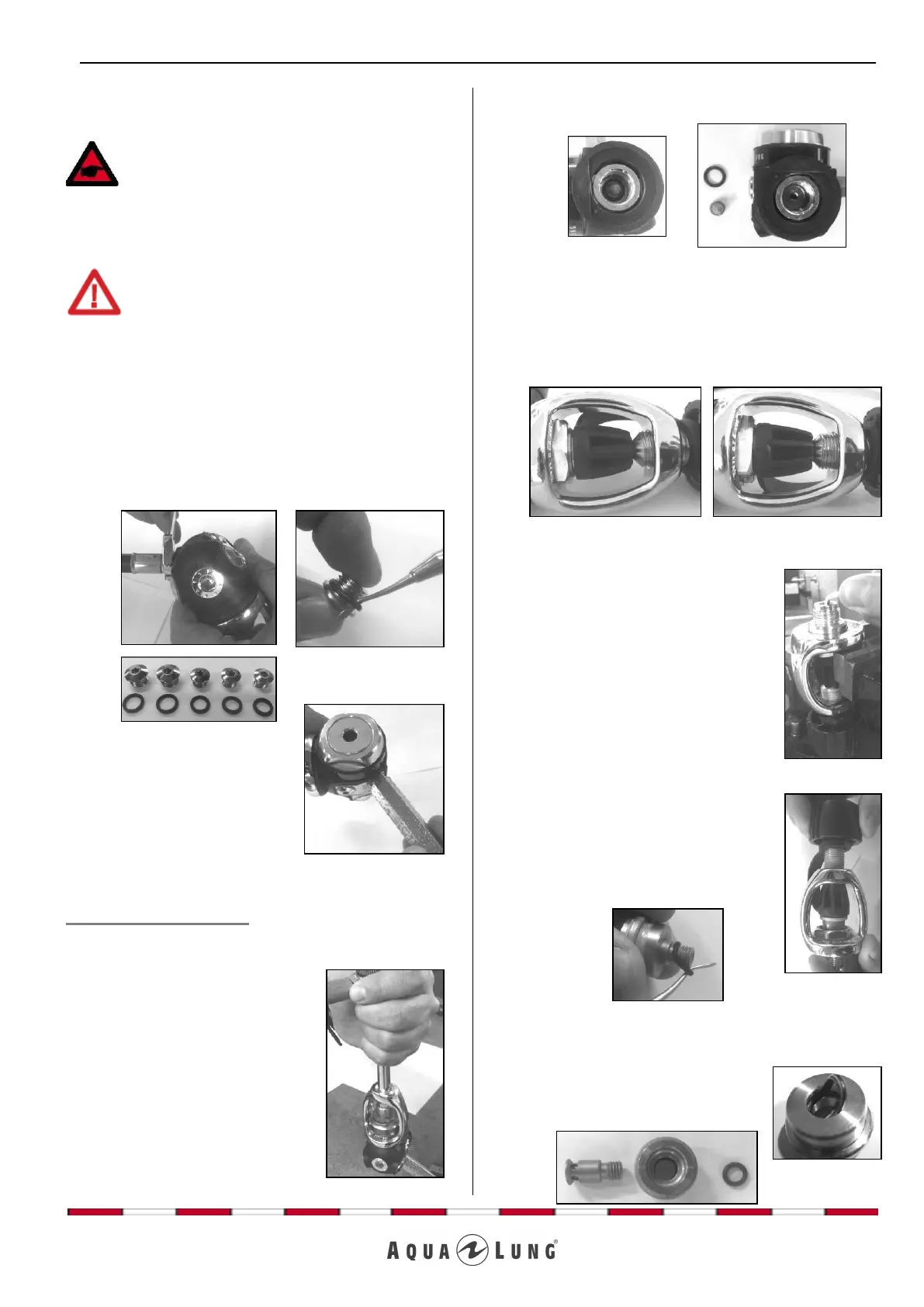

4. Take the assembly yoke retainer (129242) & yoke

(124611). Put back in place the dust cap (124555)

and the yoke screw (128631) into the yoke. Screw

the yoke screw and compress the dust cap between

the yoke retainer and the yoke screw, to open the

ACD connection (see pictures below).

Yoke screw not screwed Yoke screw enough

enough screwed

Securely clamp the assembly into

vice by gripping the yoke retainer

hexagon part with yoke connection

facing down. With a 3mm Allen key,

turn clockwise to unscrew the yoke

shutter valve (129207).

Remove the assembly from the

vice.

5. Remove the yoke screw (128631)

and the dust cap (124555) to

disassemble the system.

Using the tool (506001), remove the

O-ring (473056) of the yoke shutter

valve (129207).

Separate the yoke shutter valve from the yoke shutter

crown (129205).

Extract the O-ring (124703) from

the inside groove of the yoke

shutter crown with the tool

(506001).

NOTE: Before commencing disassembly,

consult the exploded view to check the reference

numbers of all parts requiring replacement.

These parts should all be replaced by new parts

and should not be re-used on the pretext that the

regulator has seen little use since its

manufacture or since its last service.

ATTENTION: Use only the special tool (506001)

when removing O-rings in order to avoid damaging

the seal recess. The slightest scratch on a sealing

surface could cause a leak. If a surface should be

damaged then this part should be replaced with a

new one. Do not use any pointed instrument or

metal tool to remove O-rings.

Loading...

Loading...