33

9.3 Lubrication

instructions

Maintenance work should only be

performed by specialists who are

familiar with the installed switching

devices and drive mechanisms they

use. The switching devices and

drives must not be disassembled for

service and maintenance work.

Warning!

The safety provisions

acc. to section 1.5 must

be complied with.

The closing and opening springs

must be released!

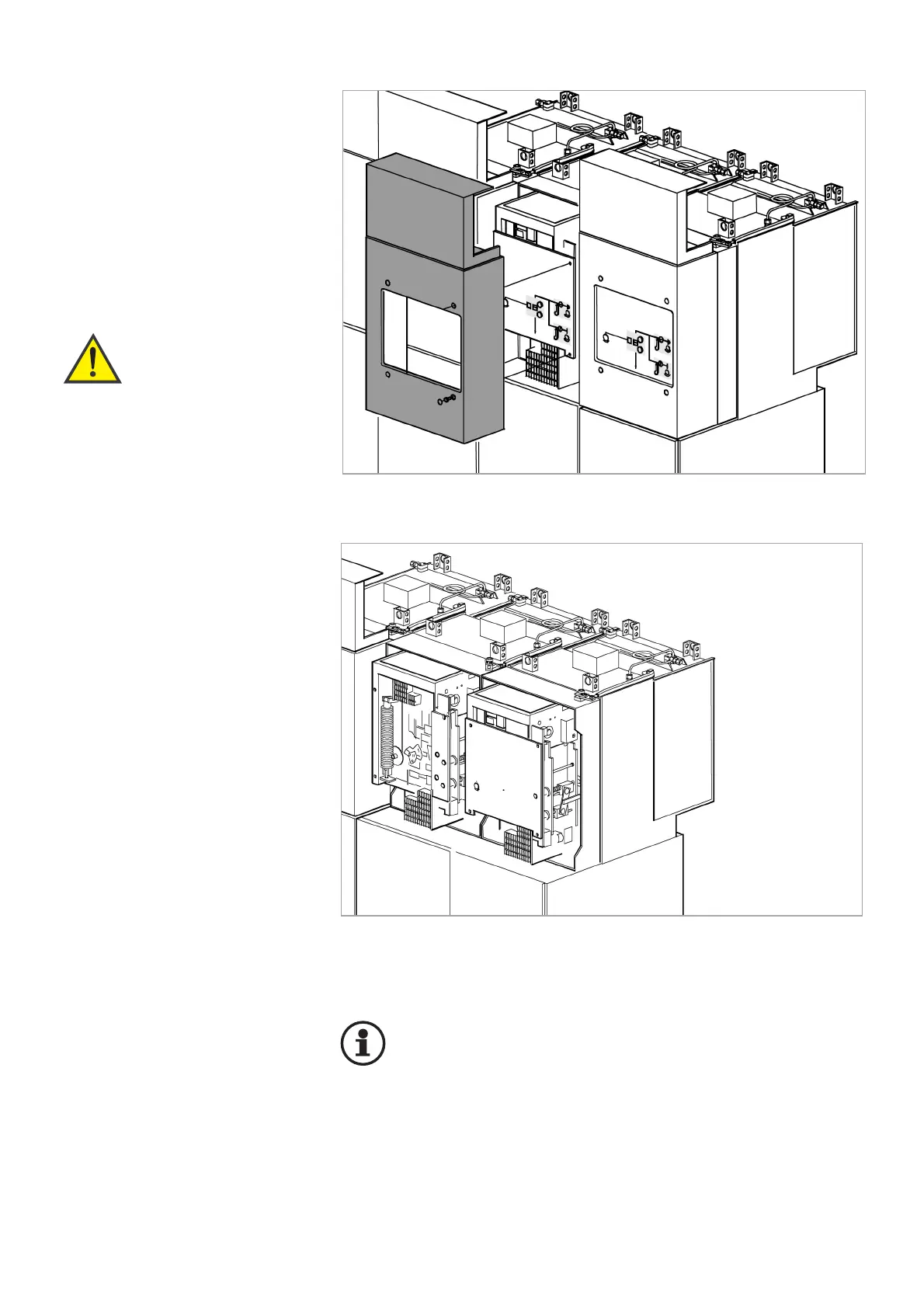

Once the front cover has been

removed, the drive is accessible from

the switchgear front end.

1. To this effect, remove the slotted

screws of the interrogating levers

(one per lever) and of the front

cover (4 ea.).

2. Remove interrogating lever.

Remove the front cover by lifting

it forward.

Access to the disconnecting and

earthing switch drives is facilitated if

the front cover of the right-hand

adjacent panel is also removed.

Once maintenance work has been

terminated, reverse disassembly

sequence to re-mount the interroga-

ting levers and the front cover.

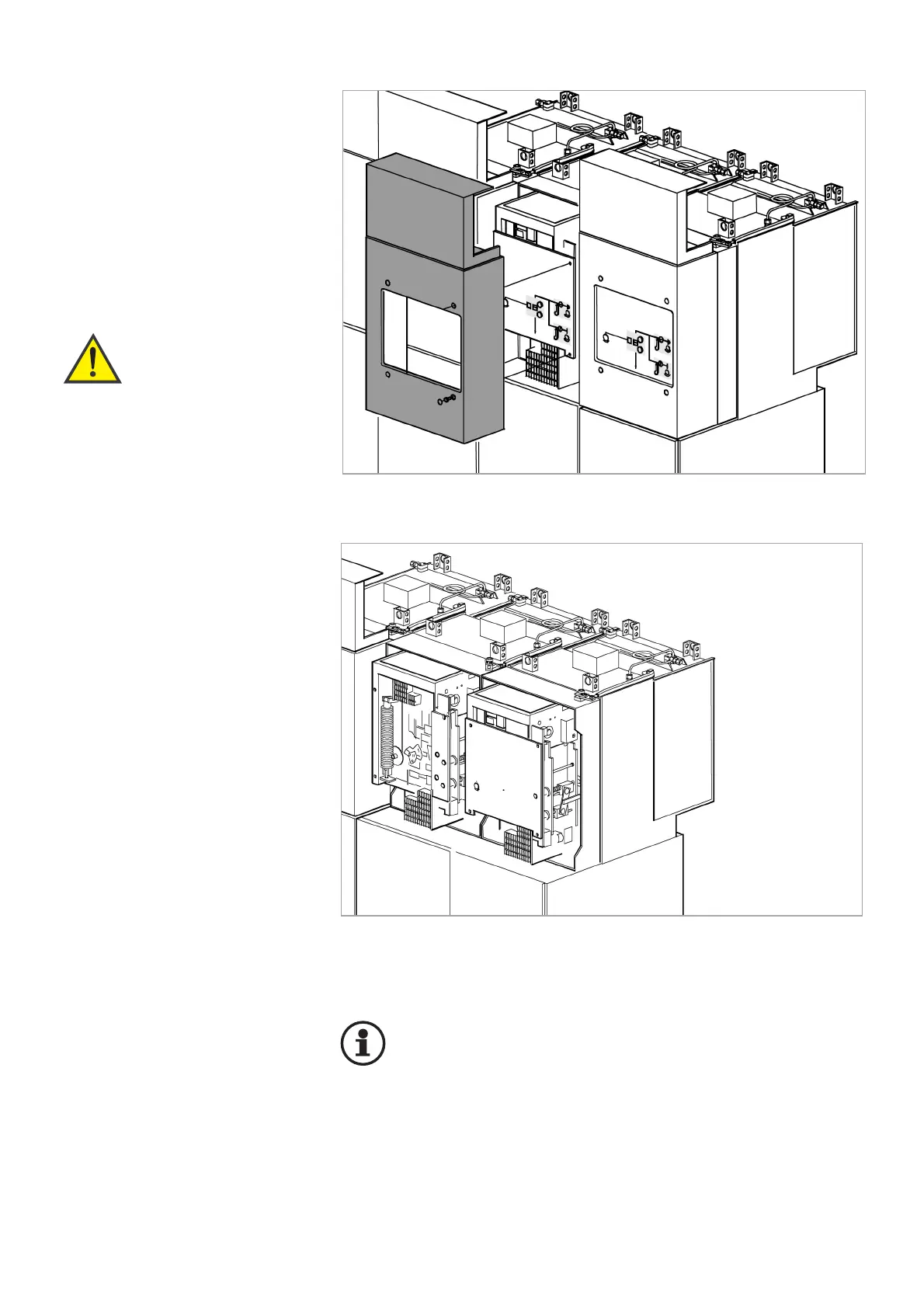

Points of lubrication:

The entire drive mechanism is lubri-

cated at the factory using the red-

coloured lubricant KL, which makes

it easily recognizable.

All surfaces and joints in the circuit-

breaker, disconnector and earthing

switch drives which are sliding on

each other must be lubricated.

Important!

The following elements

are not lubricated:

• motor

• ball bearings

• auxiliary releases

• push switches

• blocking coils

• auxiliary switches

Fig. 9.3

The lubrication points can be accessed

Fig. 9.2

Removal of the front cover

Loading...

Loading...