35

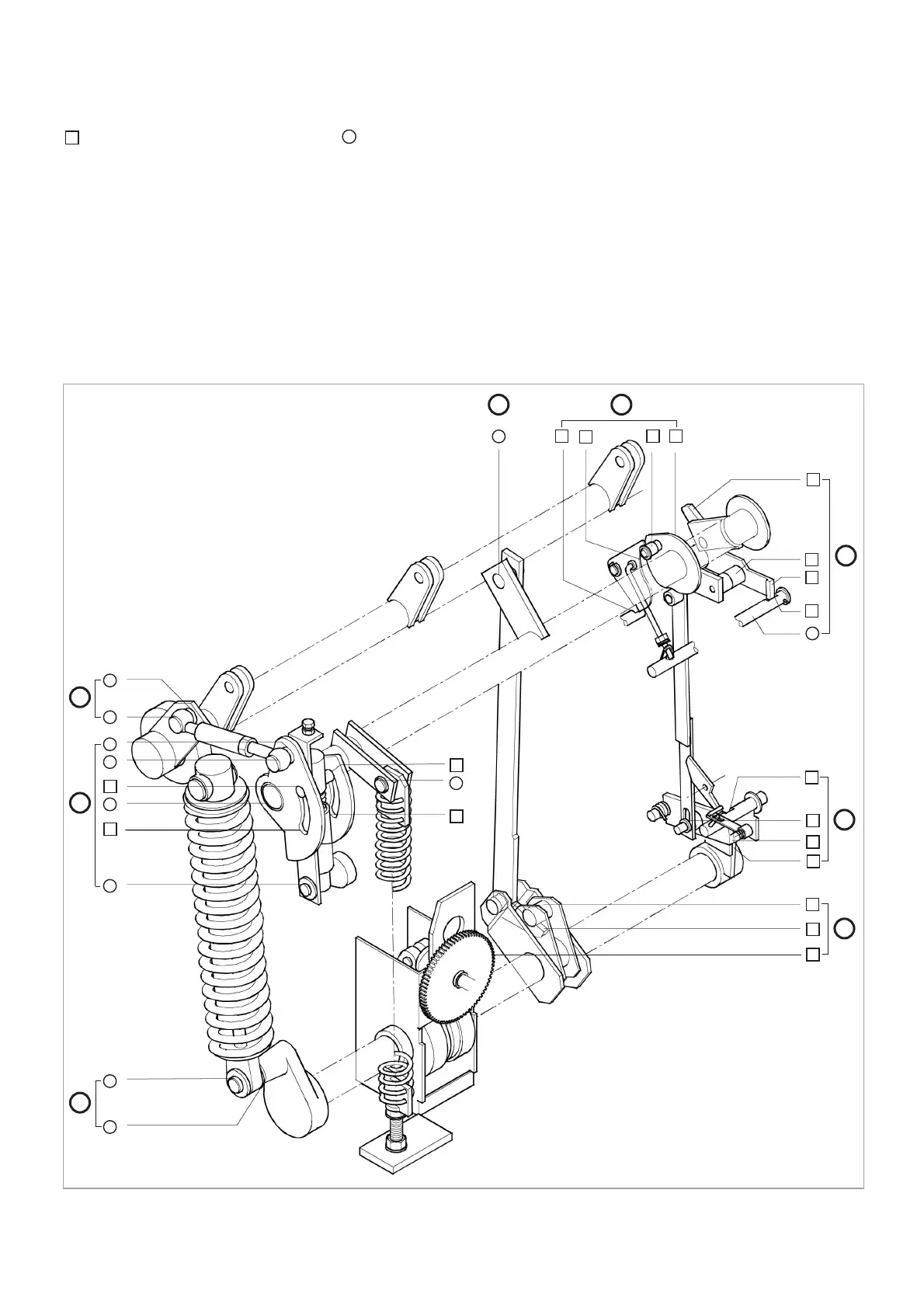

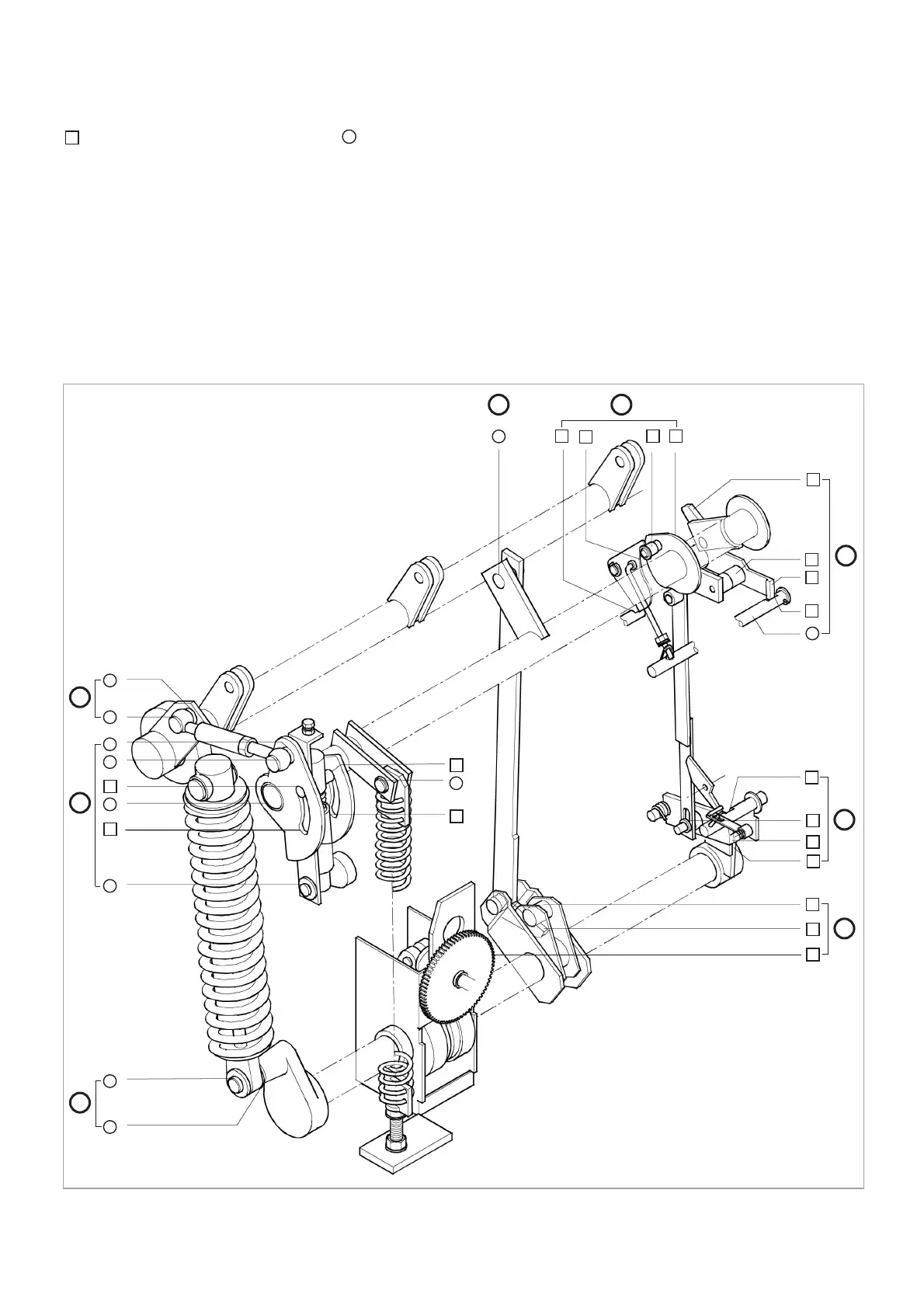

Fig. 9.5

Lubrication points in the circuit-breaker drive

Lubrication procedure

Lubricant KL

for surfaces sliding on each other.

Clean lubrication points, e.g. using a

lint-free cloth or a soft paint-brush

and detergent (use sparingly, just

moisten points of lubrication).

Apply a thin film of multi-purpose

lubricant (e.g. using a paint-brush)

Liquid lubricant FL

for bearings, joints and guide

assemblies.

Pour drops of liquid lubricant (oil

can, drip feed lubricator) into the

bearing gap. Liquid lubricant gets

between the bearing surfaces due to

the capillary effect. In case of inac-

cessible lubrication points, use an

extension tube or spray.

1

2

3

78

6

5

4

Loading...

Loading...