8

CONNECTING ELECTRICAL POWER SUPPLY

! !

WIRING THE BOILER

WARNING

DO NOT USE ALUMINUM WIRE!!

Argo Electric Hydronic Boilers are pre-wired for

use with 240-volt, 3 wire, single-phase, 50/60-hertz

power. Refer to Table 1B on page 4 for the reduction

in boiler capacity when the line voltage is less than

240 volts.

An opening is provided in the jacket bottom panel

for the eld wiring, refer to the rating chart for

recommended wire sizes.

All electrical wiring must be done in accordance with

the Canadian Electrical Code, CSA C22.1 Part 1, and

/or any local regulations and codes in Canada, or

the National Electrical code, ANSI/NFPA 70 (Latest

edition) and/or any local regulations and codes in

USA. Verify the nameplate rating and check the

related codes to properly size conductors, switches

and over current protection. Several openings are

provided on the bottom of the cabinet for different

voltage connections. For wire connections refer to

the wiring diagram on the inside of the boiler front

cover. Do not use aluminum wire!!

All circuit breakers or disconnects ahead of the boiler

must be OFF. If boiler contains integral breakers

(depending on option), it is recommended that they

are also turned off at this time. Remove the boiler front

cover by removing 4 screws from the top and sides.

When a boiler is used in a zoned system, the zone

valves must be powered from an independent

source and have electrically isolated end switches

or isolating relays wired in parallel to the boiler

thermostat terminals. Do not attempt to power

zone valves from the transformer in the boiler

control system!!

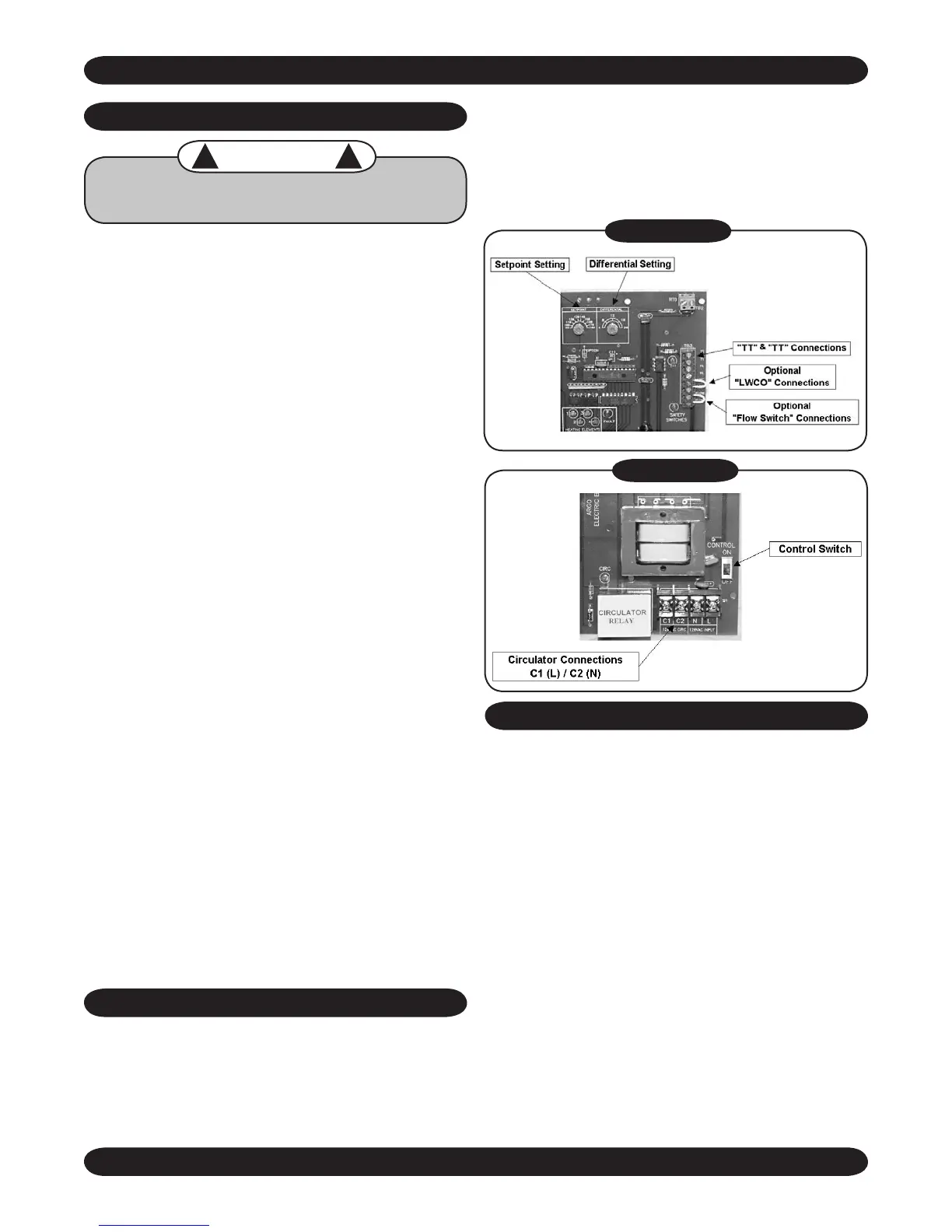

WIRING ON CONTROL

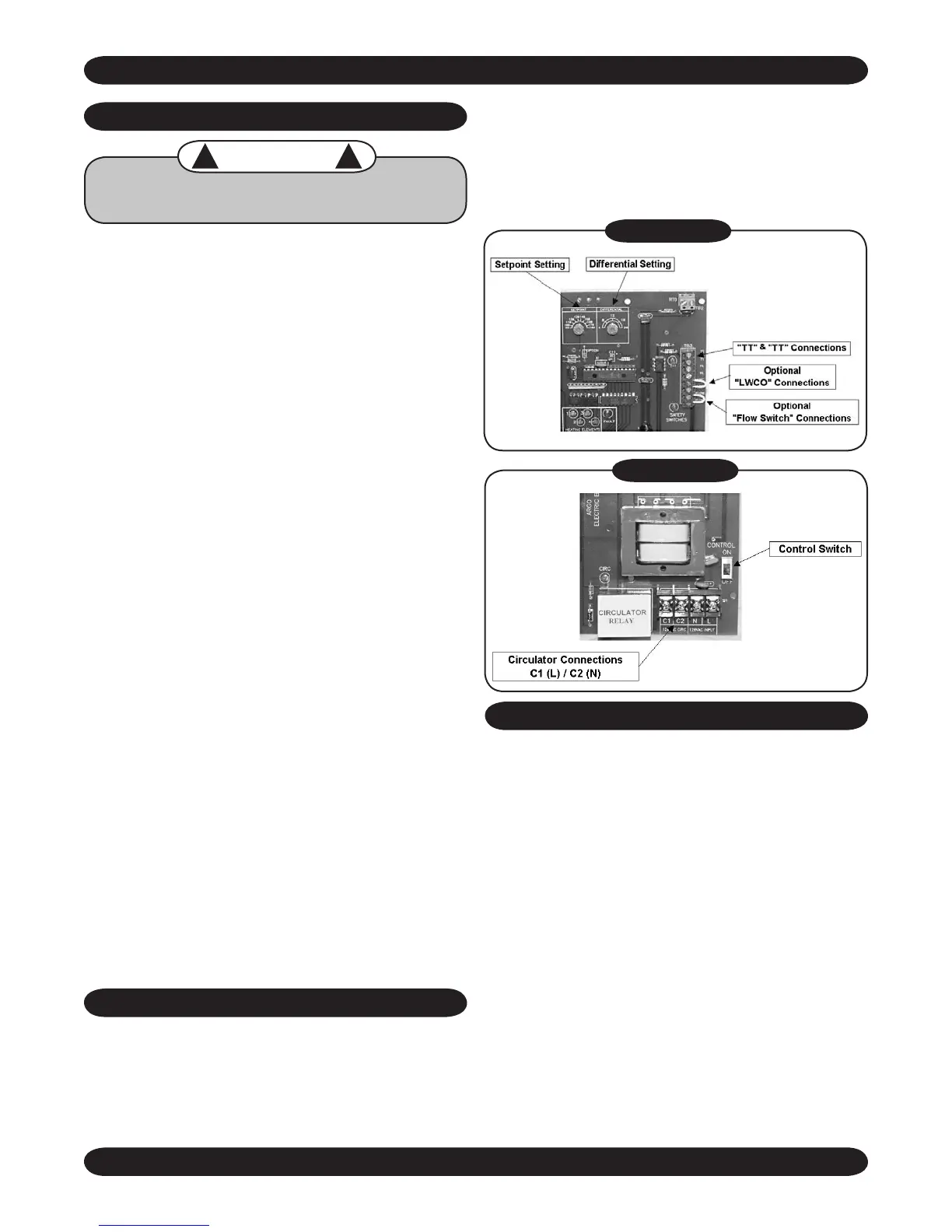

PUMP: Connect only 120 Vac 1/6 HP (maximum)

pump to terminals C1(L) and C2(N) on the controller.

Strip wire ends before inserting into terminal block.

Tighten terminal screws. Do not use a pump

requiring greater than 5 amps!!

THERMOSTAT: Connect thermostat or zone valve

end switch to terminals TT and TT (Figure 4). Do

not apply an external power source to these

terminals!! Strip wire ends before inserting into

terminal block. Tighten terminal screw clamps.

LIMIT CONTROL OPERATION

1. When the boiler water temperature exceeds the

high limit setting on the aquastat, all heating

element control relays are instantly de- energized.

Circulator continues to operate until call for heat

ends. When water temperature drops below

aquastat re-set differential, heating element power

relays close as per time delay sequence.

2. MAIN POWER SUPPLY: Depending on model

designation, the electric Hydronic Block may be

energized by the following alternating current

service entrances: 240 volt single phase 50 or

60 cycle 3 wire. The wire size required may be

selected from Table 1. The sizes listed for various

capacity units include total amperes necessary

to operate elements, circulator and zone valves

where used. Wire sizes specied conform to the

Canadian Electrical Code (Canada) or National

Electric Code (USA) and include derating for

FIGURE 4

FIGURE 5

Loading...

Loading...