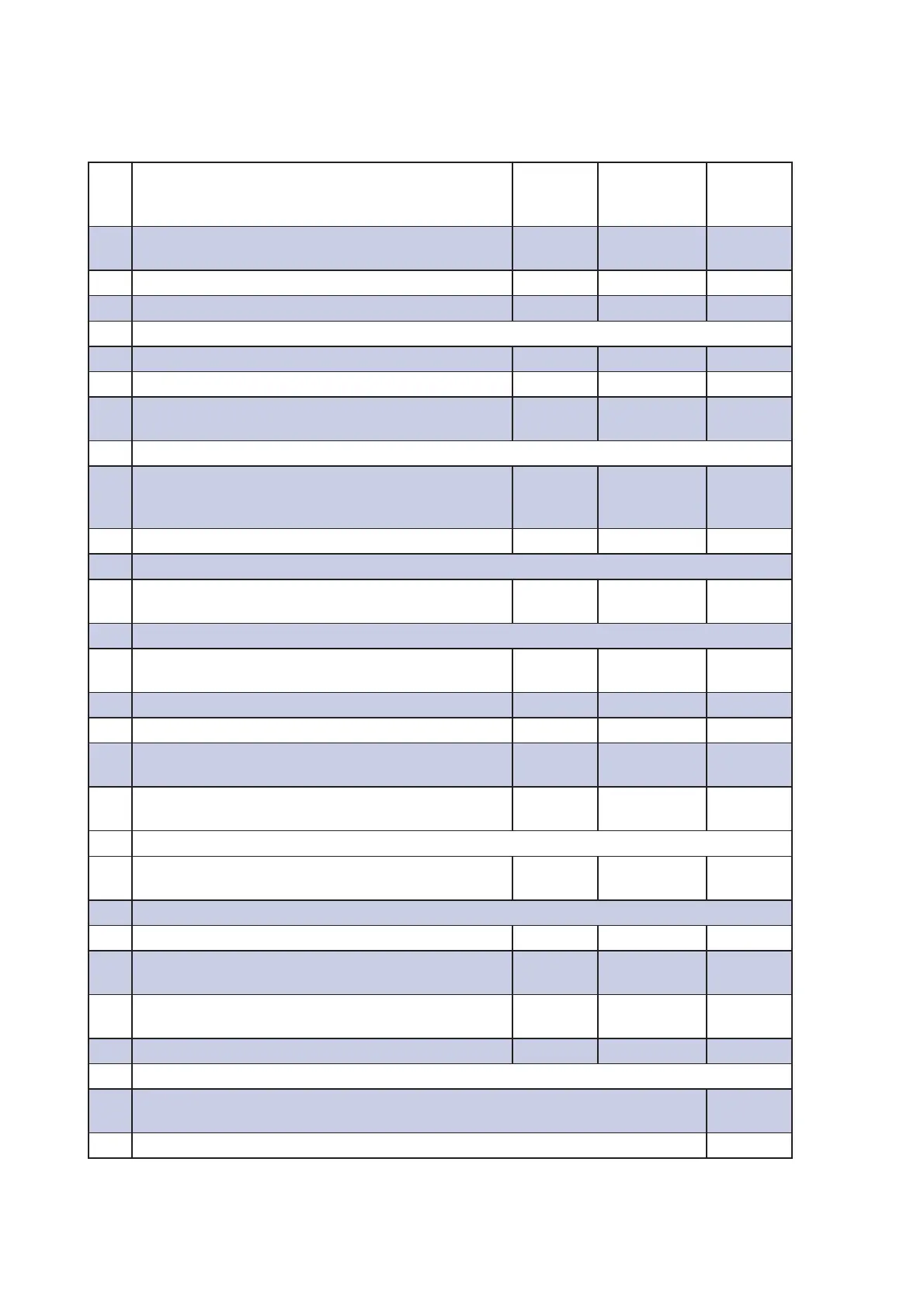

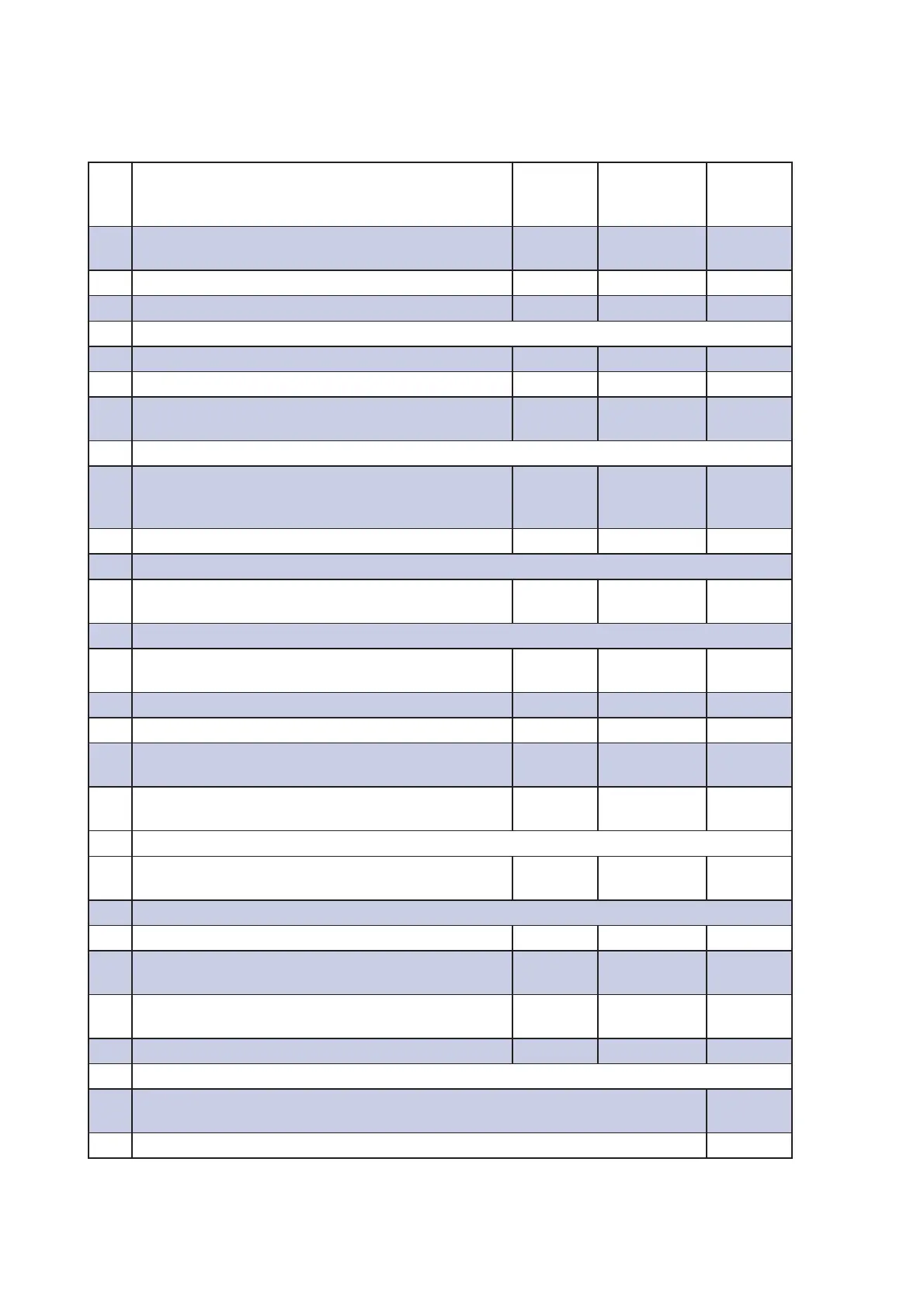

16

Measure Every

year/ 7,500

cycles

Every other

year/15,000

cycles

Time*

(minutes)

2.7 &KHFNWKDWWKHRYHUÀRZGUDLQFRQQHFWLRQWRWKH

chamber is tight.

•-

2.8 &OHDQWKHLQVLGHRIWKHÀXVKLQJFKDPEHU •10

2.9 Check the door and door spring. • 15

3 Process tank

3.1 Clean as required. • -

3.2 Check and clean the level sensor. • 5

3.3 Check that the valves are working and that the

connections are not leaking. Clean as required.

•10

4 Steam Generators

4.1 Check the connections to the steam generator for

leakage and make sure the surrounding insulation is

intact and no hot surfaces are exposed.

•5

4.2 Check that the steam generator is working properly. • 10

5 Main pump

5.1 &KHFNWKDWWKHPDLQSXPSLV¿UPO\DWWDFKHGDQGWKDW

there are no leaks in the connections.

•5

6 Dosing system

6.1 Check the hoses between the dosing pump and the

detergent holder. Replace if necessary.

• 5-10

6.2 Check the dosage amount. Adjust if necessary. • 10-30

6.3 Replace hose in the dosing pump. • 5

6.4 Check that the empty container alarm works. Clean or

replace as necessary.

•5

6.5 Check the function of the check valve in the steam

generator.

•5

7 Drainage connection

7.1 &KHFNWKDWWKHGUDLQDJHFRQQHFWLRQLV¿UPO\DWWDFKHG

and that it is not leaking.

•5

8 Ventilator (Option)

8.1 5HSODFH+(3$¿OWHU •10

8.2 Check the fan for proper operation and check that the

connections are tight.

•5

8.3 Check that the check valves are functioning properly.

Clean as required.

•10

8.4 Check hoses to the fan. • 5

10 Function check (at each service)

10.1 Run a complete process and be sure there are no deviations according to the

periodic checkpoints.

10.2 Check that the panel’s lights and alarms are functioning.

* The time required is estimated with the top off and may vary depending on the installation settings,

operating conditions and equipment level.

Loading...

Loading...