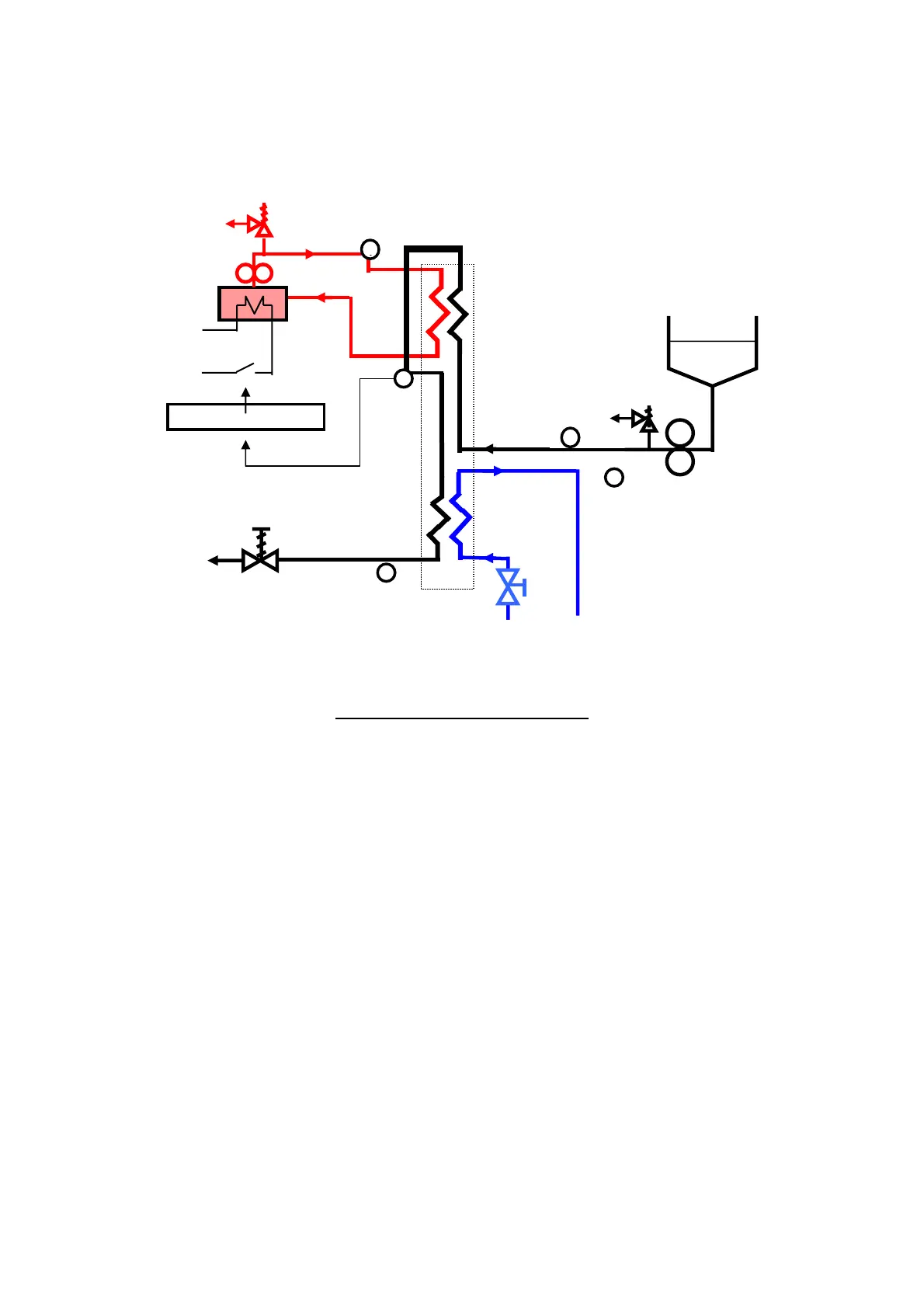

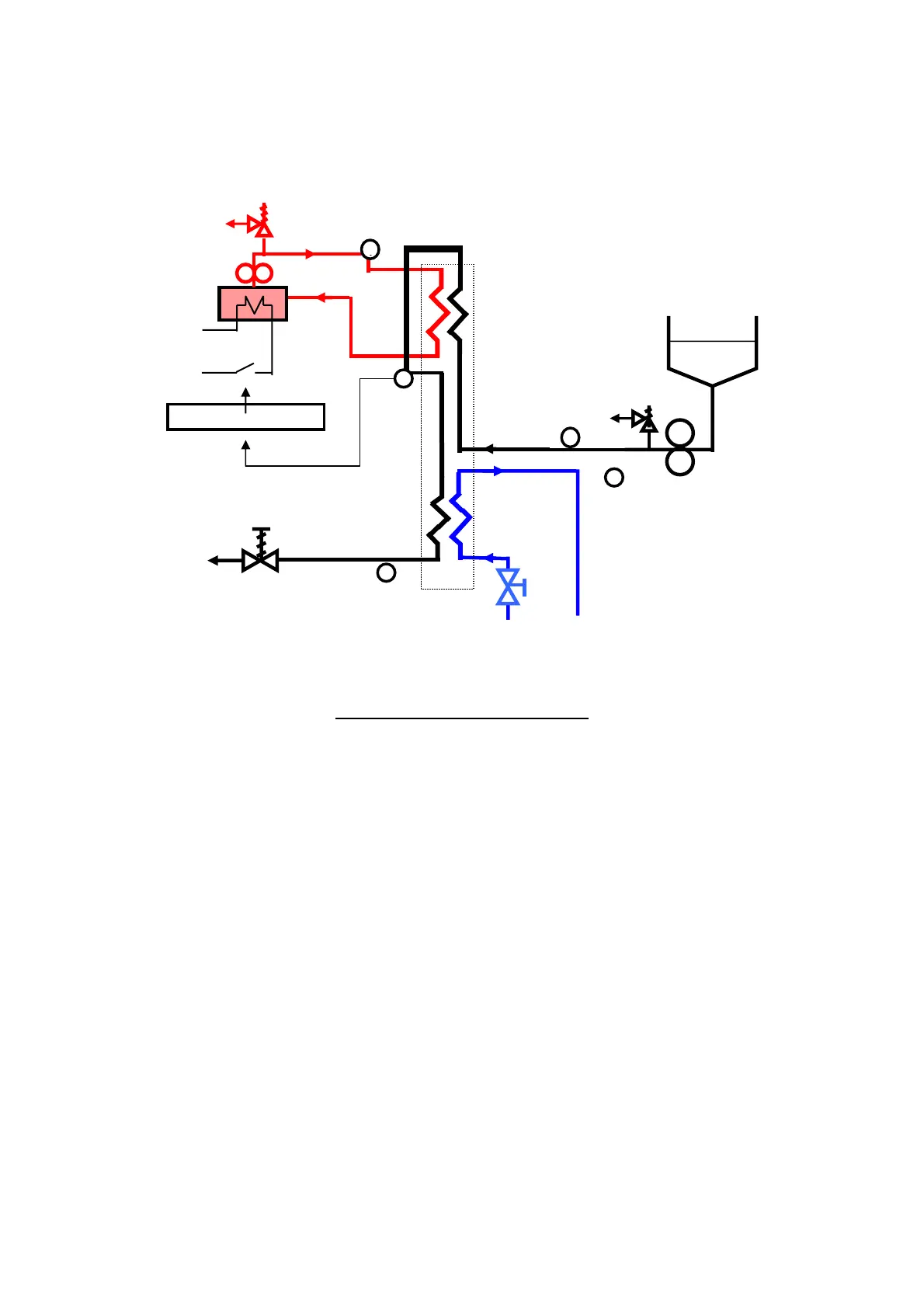

THE PROCESS

Holding Tube

Circulation

Pump

T4

Back Pressure Valve

Cooling

Section

Feed

Pump

P

T3

SSR

3 Term Controller

T1

Feed

Vessel

T2

Pressure

Pressure

Heating

Section

Cooling Water

Flow Control

Simplified Process Flow Diagram

(not showing pre-heat or re-generation stages)

The product to be processed is pumped from the Feed Vessel to the Heat Exchanger

by the Feed Pump. A Pressure Relief Valve protects the Heat Exchanger from

excessive pressure build up. Sensors measure the temperature and pressure of the

product before it enters the Heat Exchanger.

In the Heating Section of the Heat Exchanger the product is heated to the process

temperature by pressurised hot water. Note, for the purpose of simplicity, the above

diagram does not show the pre-heat section of the heat exchangers. The Plate Heat

Exchanger (FT74P) includes a re-generation stage, where the hot outgoing product is

used to pre-heat the incoming product. The Tubular Heat Exchanger (FT74T) uses

some of the pressurised hot water at a lower flow rate to pre-heat the product in a

dedicated pre-heat section. This is described in more detail in the Description section.

The pressurised hot water is generated by an electric heater contained in a heating

vessel. A pump circulates the hot water through the heat exchanger and back to the

pressurised heating vessel. A pressure relief valve provides protection against excess

pressure.

6

Loading...

Loading...