16

11 ARMITAGE BIOGUARD OUTLET

10 SERVICING - TVM3 SCHEME

10.1 FREQUENCY OF REGULAR SERVICING

The need for servicing is normally identied as a result of the regular performance auditing.

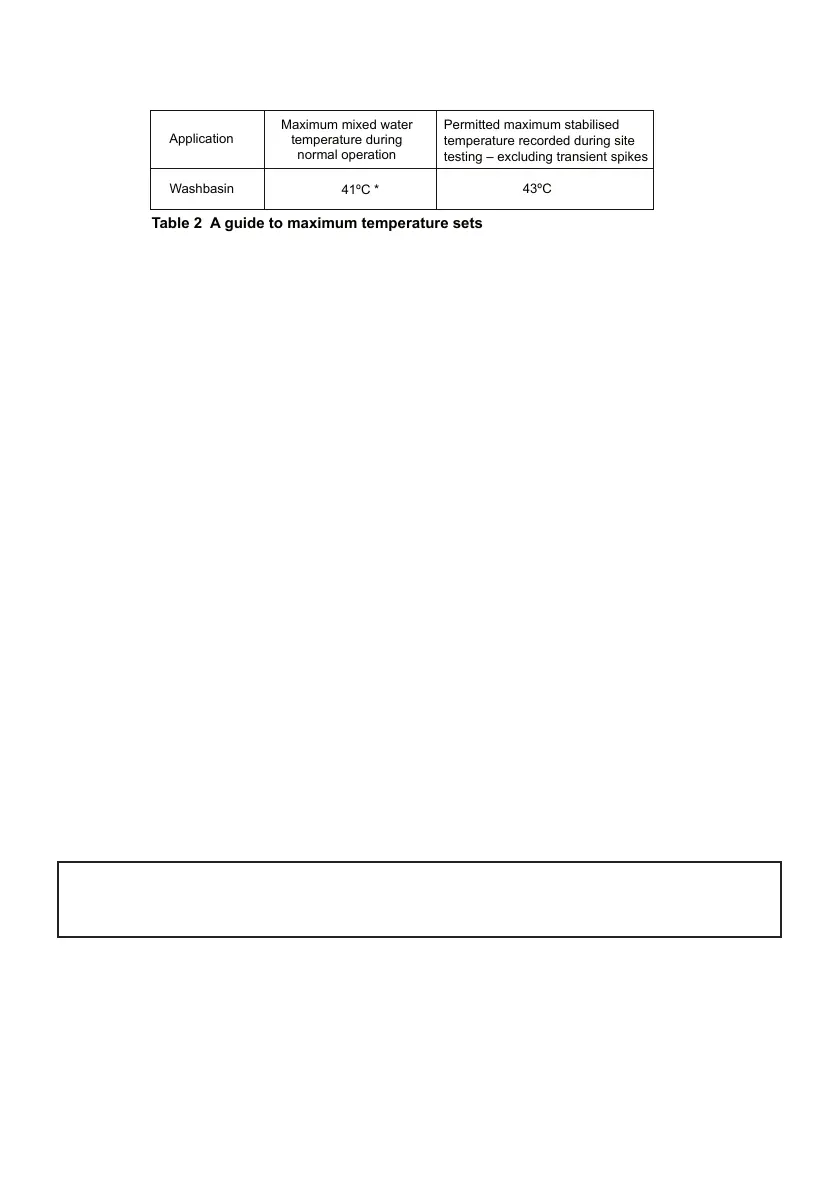

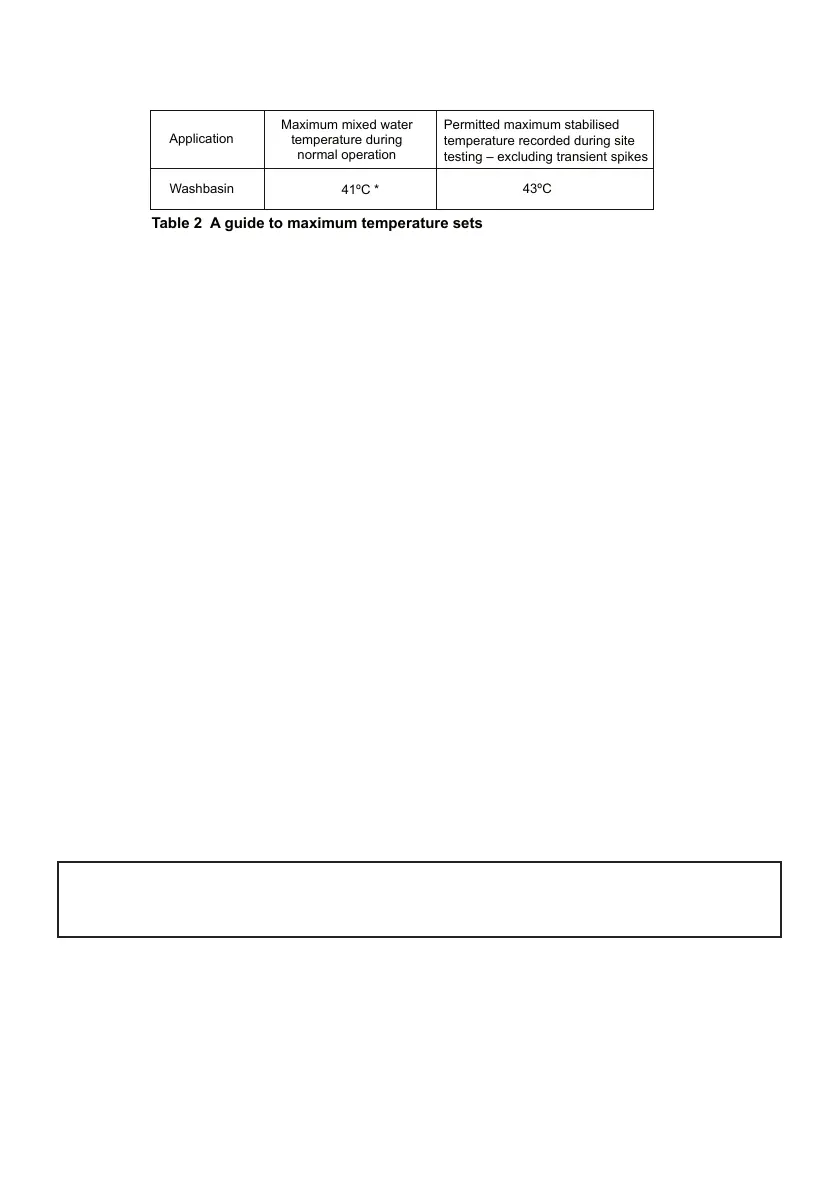

Table 2 A guide to maximum temperature sets

Permitted maximum stabilised

temperature recorded during site

testing – excluding transient spikes

The purpose of servicing regularly is to monitor any changes in performance due to changes in either

the system or the product. This may highlight the need to adjust either the supply system or the product.

These products should be audited 6 to 8 weeks and again 12 to 15 weeks after commissioning. The

results are to be compared against original commissioning settings. If there are no signicant changes

at the mixed temperature outlet then a 6 monthly servicing cycle may be adopted. Otherwise, servicing

checks should be carried out more frequently (e.g. every 4 months).

Follow the recommended auditing and maintenance procedures detailed in sections 9 & 12. During

servicing, note the following:

1. Repeat the procedure of recording and checking supply temperatures. (The same type of measuring

equipment should be used)

2. If the temperature has changed signicantly from the previously recorded valves, the following should

be checked:

a. All in-line or integral valve lters are clear of obstruction.

b. All in-line or integral check valves are clean and working properly to prevent backow.

c. Any isolating valves are fully open.

d. The thermostat is free of debris

3. When satised with the mixed outlet temperatures re-record the temperatures.

11.1 Outlet cleaning

Traditional “ow straightener” type outlets have recently been identied by extensive research as an

area most likely to harbour bacteria. This product uses an Armitage Bioguard outlet which replaces this

traditional ow straightener with a fully open copper-lined waterway. This greatly reduces the risk of

bacteria build-up whilst the copper lining has natural anti-microbial properties.

Outlet is suitable for autoclaving (remove o-ring if exceeding 80°C).

In the interests of infection control and health hygiene, the Armitage Bioguard Outlet is a supplement to,

not a substitute for, standard infection control practices. Continue to follow all current protocols, includ-

ing those practices related to cleaning and disinfection of surfaces. Refer to HTM04-01 for more details.

Patent pending for Armitage Bioguard antibacterial outlet, application No: 10 2012 107 243.4

On a regular basis the outlet should be inspected and cleaned.

To unscrew and remove the outlet, use an adjustable spanner on the ats (20mm). To ret, hand tighten

and then use the spanner until the outlet has bottomed in the bore. Take care not to over tighten.

In areas where lime scale build-up is prevalent this should be avoided by regular cleaning. If it should

build up, it will have to be removed. An inhibited proprietary scale solvent can be used such a kettle des-

caling solvent but it is important to follow the manufacturer’s guidelines. After descaling it is important to

rinse the parts thoroughly in clean water. Clean carefully and do not use abrasive materials or scrapers

Note: Lime scale deposits should be removed prior to using any disinfection treatments.

OUTLET FILTER: The Armitage Bioguard outlet can be removed (as described below) & re-

placed with a universal lter adaptor, see section 18. The adaptor will accept most lter types

which are externally threaded M24x1.

* See section 9.6: setting temperature

Loading...

Loading...