Ascon Tecnologic - K Series - ENGINEERING MANUAL - Vr. 9.0 PAG. 21

]Ser Group - Serial link parameters

[123] Add - Instrument address

Available: Always.

Range: oFF = Serial interface not used;

1... 254 Instrument address.

[124] bAud - Baud rate

Available: When [123] Add different from oFF.

Range: 1200 = 1200 baud;

2400 = 2400 baud;

9600 = 9600 baud;

19.2 = 19200 baud;

38.4 = 38400 baud.

[125] trSP - Selection of the value to be

retransmitted (Master)

Available: When [123] Add is different from oFF.

Range: nonE = Retransmission not used (the instrument is

a slave);

rSP = The instrument becomes a Master and

retransmits the operative set point;

PErc = The instrument becomes a Master and

retransmits the power output.

Note: For more details see [80] SP.rt (Remote set point type)

parameter.

]COn Group - Consumption parameters

[126] Co.tY - Measurement type

Available: Always.

Range: oFF = Not used;

1 = Instantaneous power (kW);

2 = Power consumption (kW/h);

3 = Energy used during program execution. This

measure starts from zero when the program is

launched and stops when the program ends.

A new program execution resets the value;

4 = Total worked days with threshold. Number of

hours that the instrument has been turned ON

divided by 24.

5 = Total worked hours with threshold. It is the

number of hours that the instrument has been

turned ON.

Note: Selections 3 and 4 use an internal counter for machine

service inspection intervals. The counter works every

time the instrument is turned ON. When the count

reaches the programmed threshold, the display shows

alternately the standard display and the message

r.iSP (requested Inspection). The count reset can be

done only by changing the threshold value.

[127] UoLt - Nominal Voltage of the load

Available: When [126] Co.tY = 1 or [126] Co.tY = 2 or

[126] Co.tY = 3.

Range: 1... 9999 (V).

[128] cur - Nominal current of the load

Available: When [126] Co.tY = 1 or [126] Co.tY = 2 or

[126] Co.tY = 3.

Range: 1... 999 (A).

[129] h.Job - Threshold of the working period

Available: When [126] Co.tY = 4 or [126] Co.tY = 5.

Range: oFF = Threshold not used;

1... 999 days;

1... 999 hours.

]CAL Group - User calibration group

This function allows to calibrate the complete measuring

chain and to compensate the errors due to:

– Sensor location;

– Sensor class (sensor errors);

– Instrument accuracy.

[130] AL.P - Adjust Low Point

Available: Always.

Range: From -1999 to (AH.P - 10) engineering units.

Note: The minimum differance between AL.P and AH.P is

10 engineering units.

[131] ALo - Adjust Low Offset

Available: Always.

Range: -300... 300 engineering units.

[132] AH.P - Adjust High Point

Available: Always.

Range: From (AL.P + 10) to 9999 engineering units.

Note: The minimum differance between AL.P and AH.P is

10 engineering units.

[133] AL.o - Adjust Low Offset

Available: Always.

Range: -300... 300 engineering units.

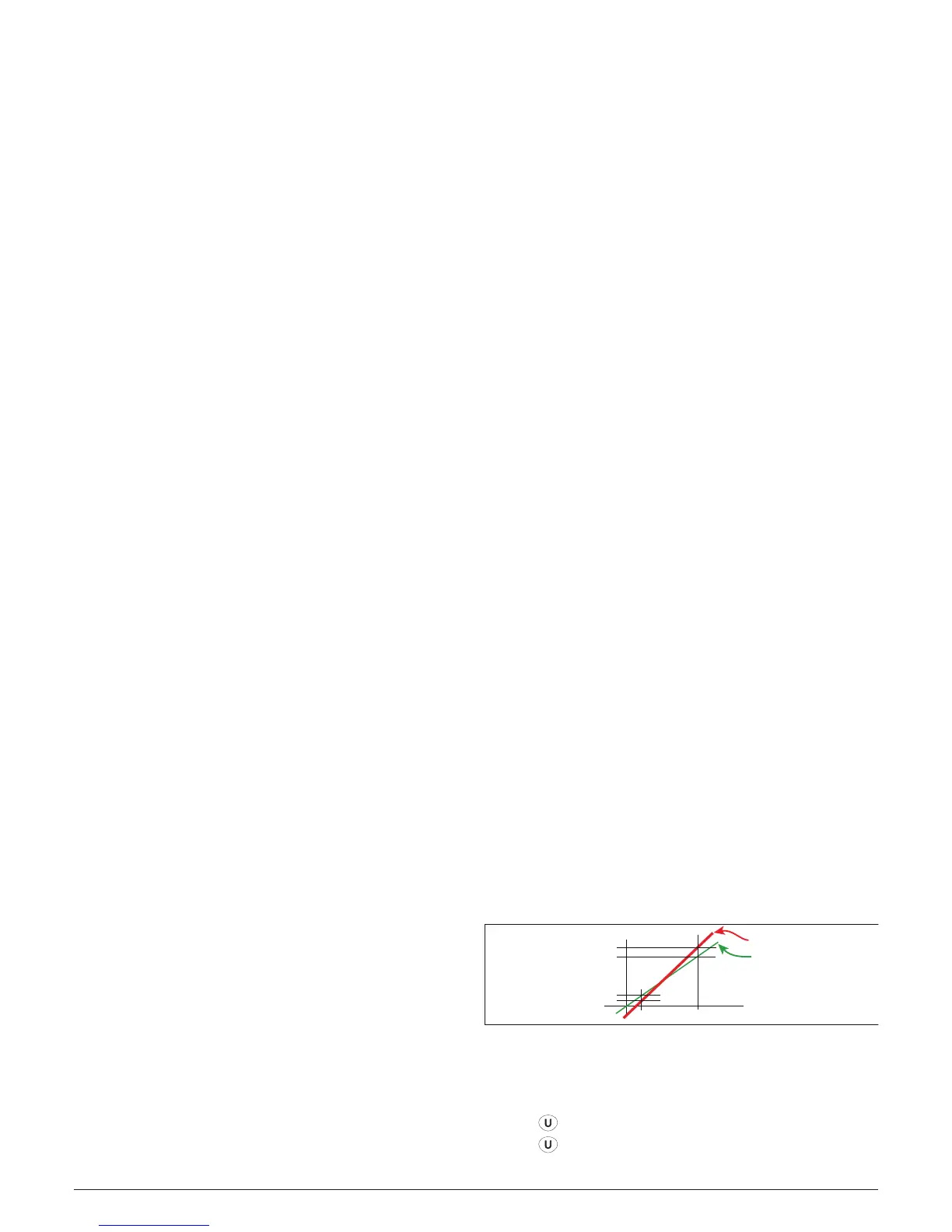

Example: Environmental chamber with an operative range

from 10 to + 100°C.

1. Insert in the chamber a reference sensor connected with

a reference instrument (usually a calibrator);

2. Start the control of the instrument and set a set point equal

to the minimum value of the operative range (e.g. 10°C).

When the temperature in the chamber is steady, take

note of the temperature measured by the reference

system (e.g. 9°C).

3. Set [130] AL.P = 10 (low working point) and

[131] ALo = -1 (the difference between the values readed

on the instrument and on the reference system).

Note that after this set, the instrument measured value is

equal to the measured value of the reference system.

4. Set a set point equal to the maximum value of the

operative range (e.g. 100°C). When the temperature

in the chamber is steady, take note of the temperature

measured by the reference system (e.g. 98°C).

5. Set [132] AH.P = 100 (high working point) and

[133] ALo = +2 (the difference between the values readed

on the instrument and on the reference system).

Note that after this set, the instrument measured value is

equal to the measured value of the reference system.

AH.P 100°C

AH.o = 2

AL.o = -1

AH.P 10°C

Real curve

Modified curve

The most important step of the configuration procedure is

completed.

In order to exit from configuration parameter procedure,

proceed as follows:

– Press

button;

– Press

button for more than 10 seconds;

– The instrument returns to the “Standard display”.

Loading...

Loading...