Service manual DW90

13

Component description

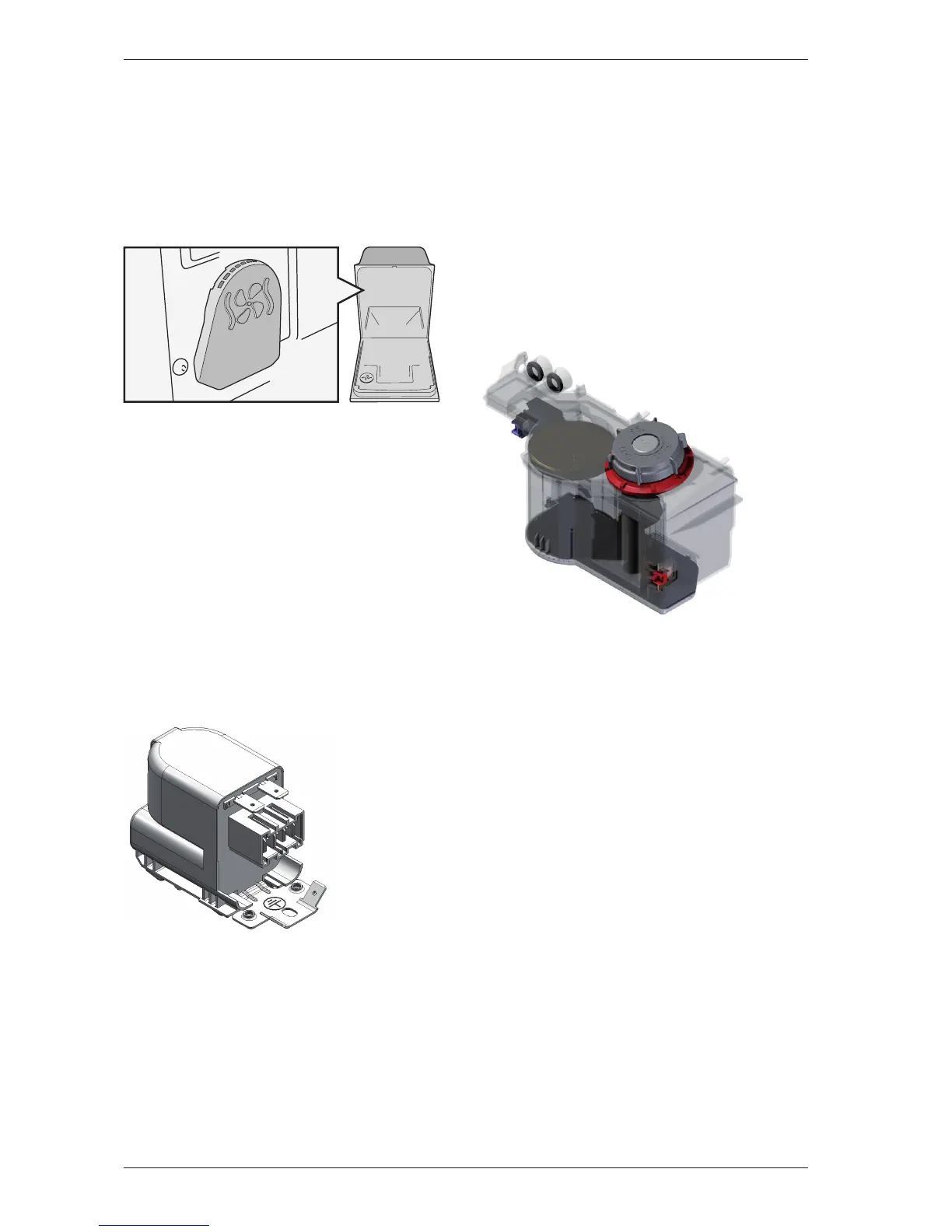

Turbo Drying Express (TDE)

Certain machines are equipped with Turbo Drying

Express, which provides more efficient drying,

among other things. Hot air is blown into the cleaning

compartment and used for drying and warming

crockery. The air is vented by the normal fan.

The nozzle that blows the hot air is fitted to the

side wall of the cleaning compartment.

Main power switch

The main power switch has 2 pins and breaks the

phase and the earth. However, power to the filters,

overflow guard, drain pump and inlet valve is not

cut when the main power switch is turned off.

On the DW90.2 the main power switch is

electronic and is integrated with the control unit.

The machine switches to standby when the main

power switch is deactivated and when the door is

closed. Standby is deactivated when the main power

switch is activated and when the door is opened.

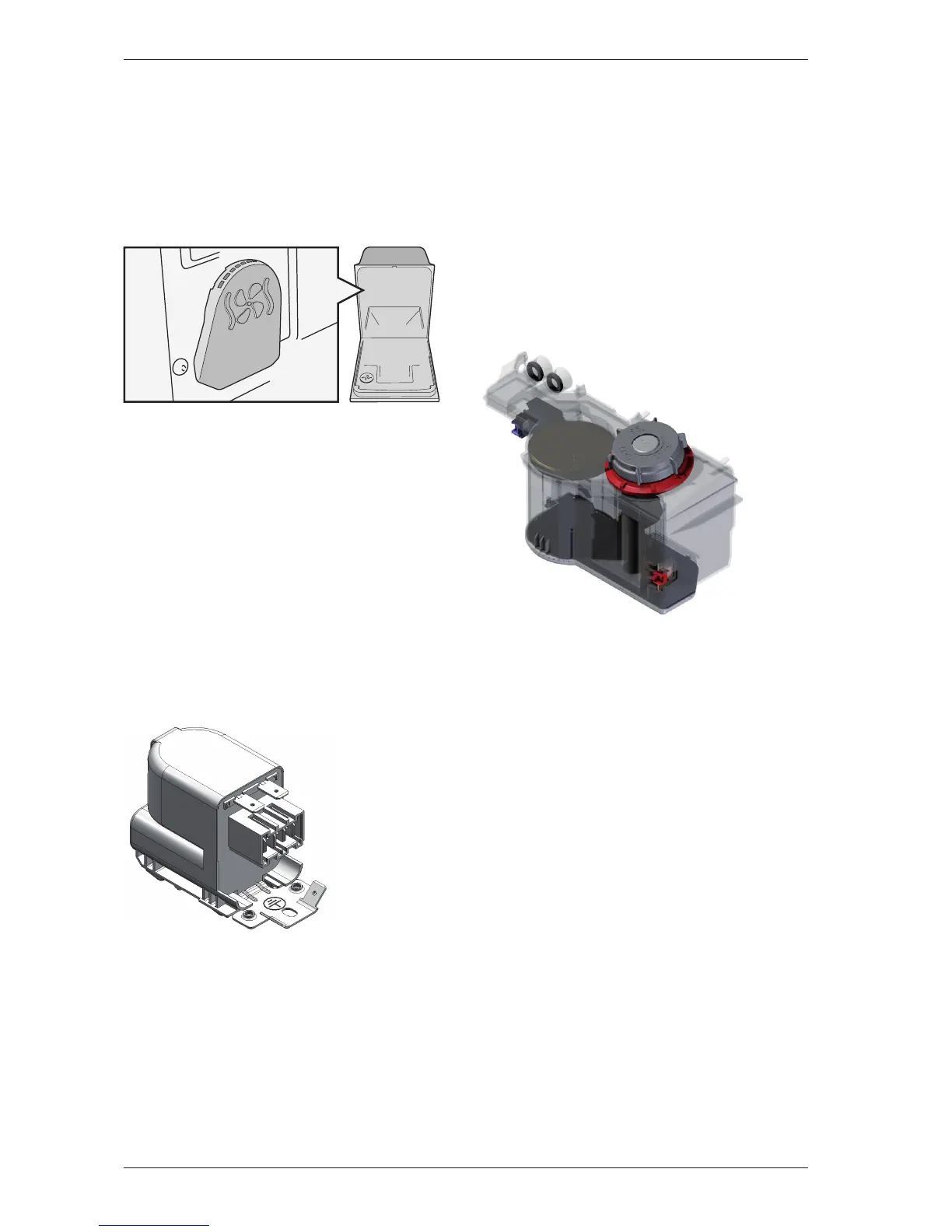

EMC filter with inductor

The filter is fitted at the front of the bottom

plate and consists of a number of coils,

condensers and resistors.

Purpose: To eliminate electromagnetic

interference to and from the machine.

Door switch

A micro switch detects when the door has been

opened. The program is paused and power to

certain components (circulation pump, valves

and more) is cut. The program continues where

it left off when the door is closed. If a program

is running the machine indicates that the door is

open.

Purpose: To prevent the machine from running

while the door is open.

Water softener

Certain machines are fitted with a water

softener. The water softener is under the cleaning

compartment and has a cap for topping up the salt in

the bottom of the cleaning compartment. The water

softener has two chambers, one for salt and one for

ion exchange resin. It also has two electromagnetic

valves (a mixer valve and a salt valve) which control

the water flow to the salt chamber and through

the ion exchange resin. When filling with water,

the water flows through the chamber containing

the ion exchange resin where the hard water is

softened. The mixer valve is used to control whether

the incoming water flows through or bypasses the

chamber containing ion exchange resin depending

on the water hardness setting. The salt valve is used

to fill the chamber containing the ion exchange resin

with water saturated with salt from the salt chamber

when the ion exchange resin needs to be recharged.

When the salt valve opens the water pocket in the

air gap is emptied, with the water passing through the

salt chamber and into the chamber containing the ion

exchange resin.

Loading...

Loading...