PHOENIX Talon - Operation and Service Manual

13

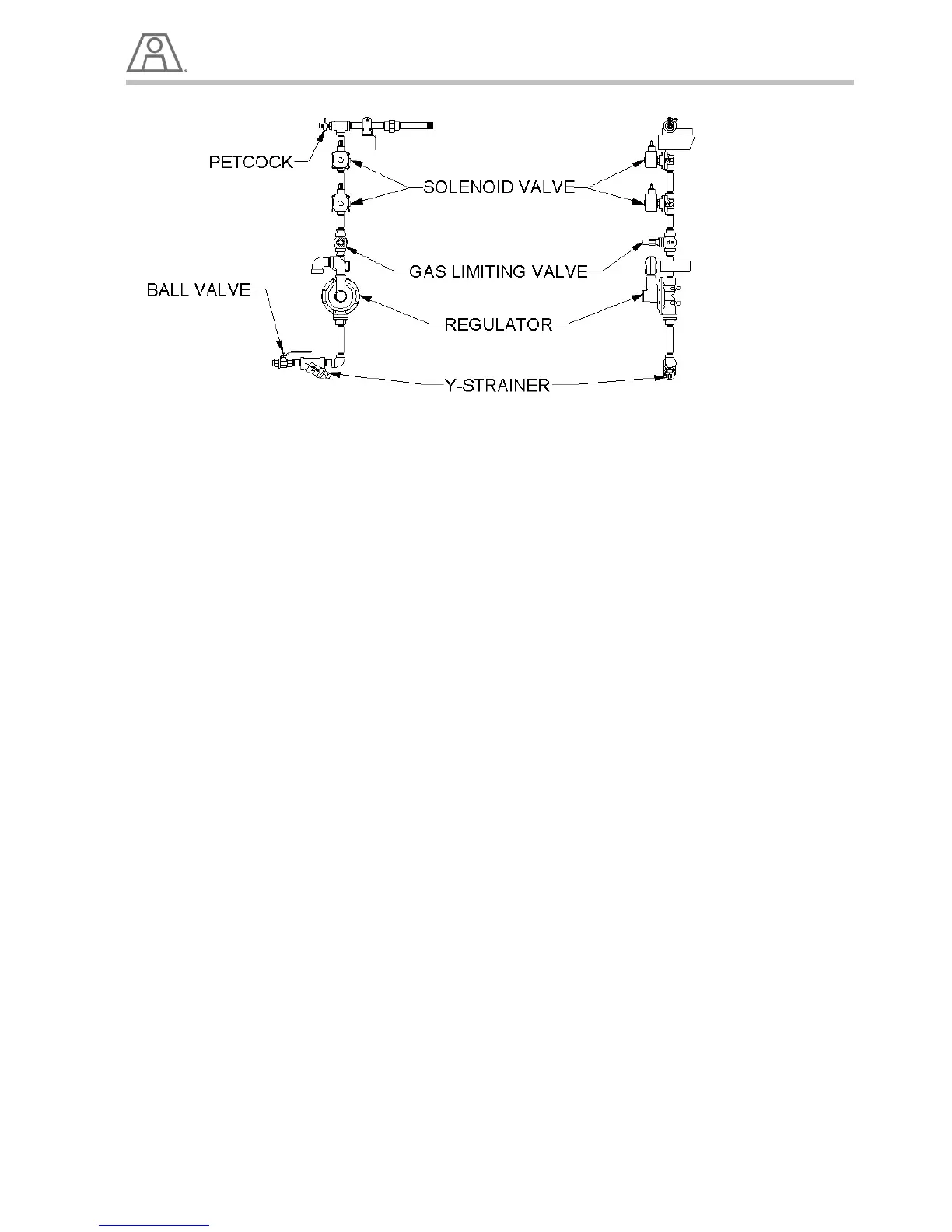

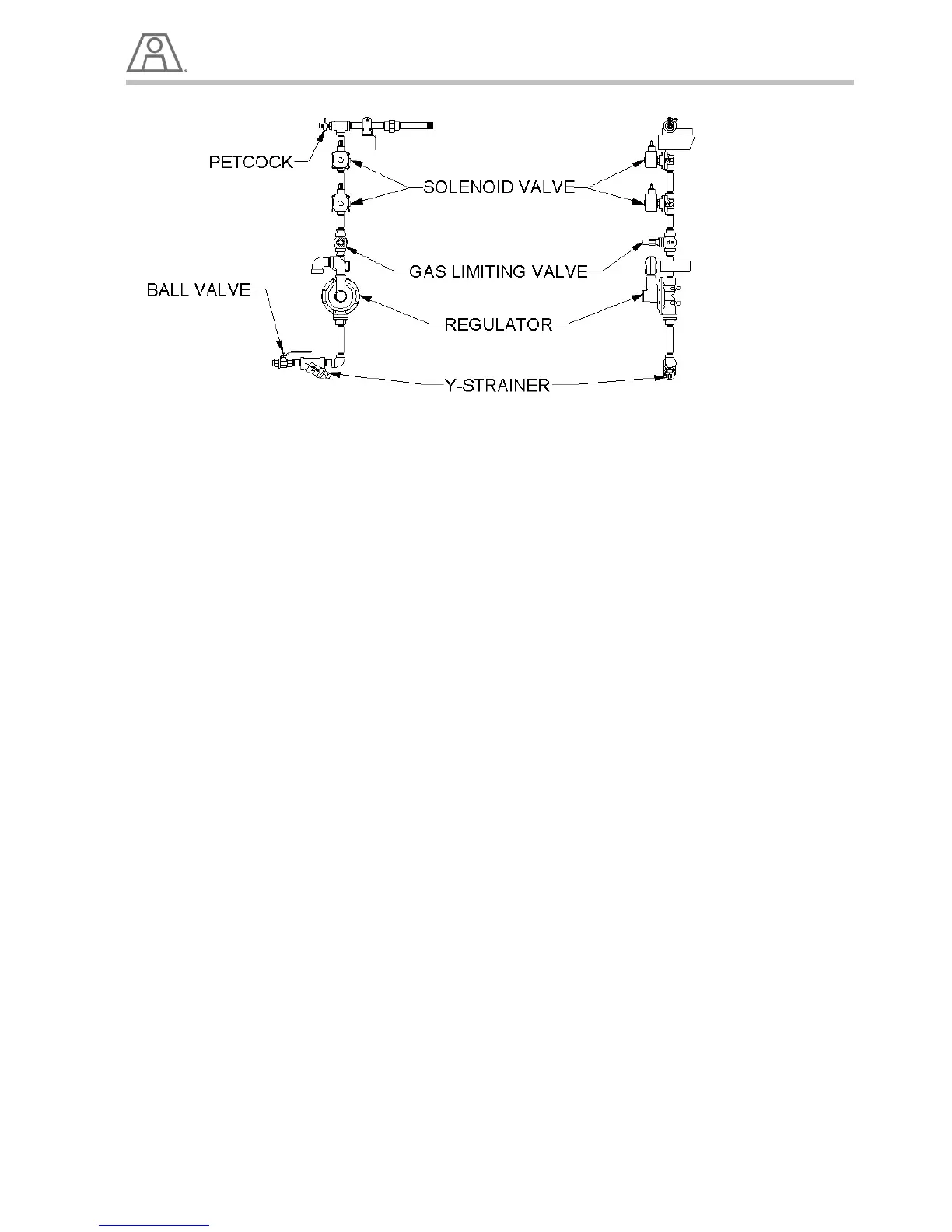

Illustration 5 – Typical Pilot Gas Train

Adjustment and Operation of the Pilot System

1. Use Natural Gas (NG) or Liquid Propane (LP) vapor only to fuel the pilot.

WARNING!

Never connect the LP fuel line to the pilot from the bottom of the LP tank. LP would likely be sent to

the pilot, where it could quickly boil off, causing either an explosion or fire in the burner.

2. If natural gas is the primary fuel, the pilot fuel supply should be connected to the natural gas feed

piping, upstream of the main regulator.

3. If you will be firing using liquid fuels, and/or natural gas service is not currently available, connect the

gas feed piping to a LP vapor line. (See above warning.)

4. Purge the fuel piping of any contaminates before connecting it to the pilot assembly.

5. Size the pilot gas supply line to avoid an excessive pressure drop. (For a pilot gas supply line up to

50 feet long, use a minimum of 3/8" pipe.)

6. Gas pressures at the inlet of the gas pilot manifold can range from 2 to 40 psig.

7. The entire pilot/oil gun assembly can be removed from the burner by removing the bolts on flange at

the back of the burner, then pulling the assembly backwards.

8. Remove the spark plug wire boot, then the spark plug can be removed with a standard spark plug

socket.

The Initial Pilot Adjustment

1. Make sure the spark igniter is connected to the ignition transformer.

2. The initial recommended pressure setting is approximately 5” water column for vaporized propane,

10” water clumn for natural gas (at the test port).

3. At this rate the pilot should light the main burner easily, and deliver a sufficient UV flame signal.

Loading...

Loading...