Page 8

12. Place a small stack of envelopes in Guides.

13. Using adjusting thumbscrew, make sure right edge of Push Guide is perpendicular to

Front Stop Plate for accurate squareness.

14. Turn Feeder ON, set Mode Switch to MANUAL. Turn Speed Control clockwise so

Conveyor Tapes are moving slowly.

15. Turn Vacuum Switch ON.

16. Press SET-UP Switch momentarily. This activates Suction Cup Bar and brings down an

envelope. When envelope moves down Conveyor to Duplicator, make sure it clears Push

Guide and does not touch springs on Stop Guide.

17. Turn VACUUM Switch OFF and press SET-UP Switch again. This activates jogging

mechanism. Adjust Jogger Guide so envelope just touches springs on Stop Guide.

NOTE: TOO MUCH JOG CAN AFFECT REGISTRATION.

18. Adjust Conveyor Tapes by moving Tape Guides (located under Conveyor portion of

Feeder) while tapes are running slowly.

EXAMPLE: For No. 10 envelopes, use three (3) tapes. One over Stop Guides

(approx. 3/8" (1 cm) from springs), one over Push Guide (approx. 1/4" (6 mm) from

right edge) and one tape under skid wheel. For wider envelopes, use additional tapes

as needed.

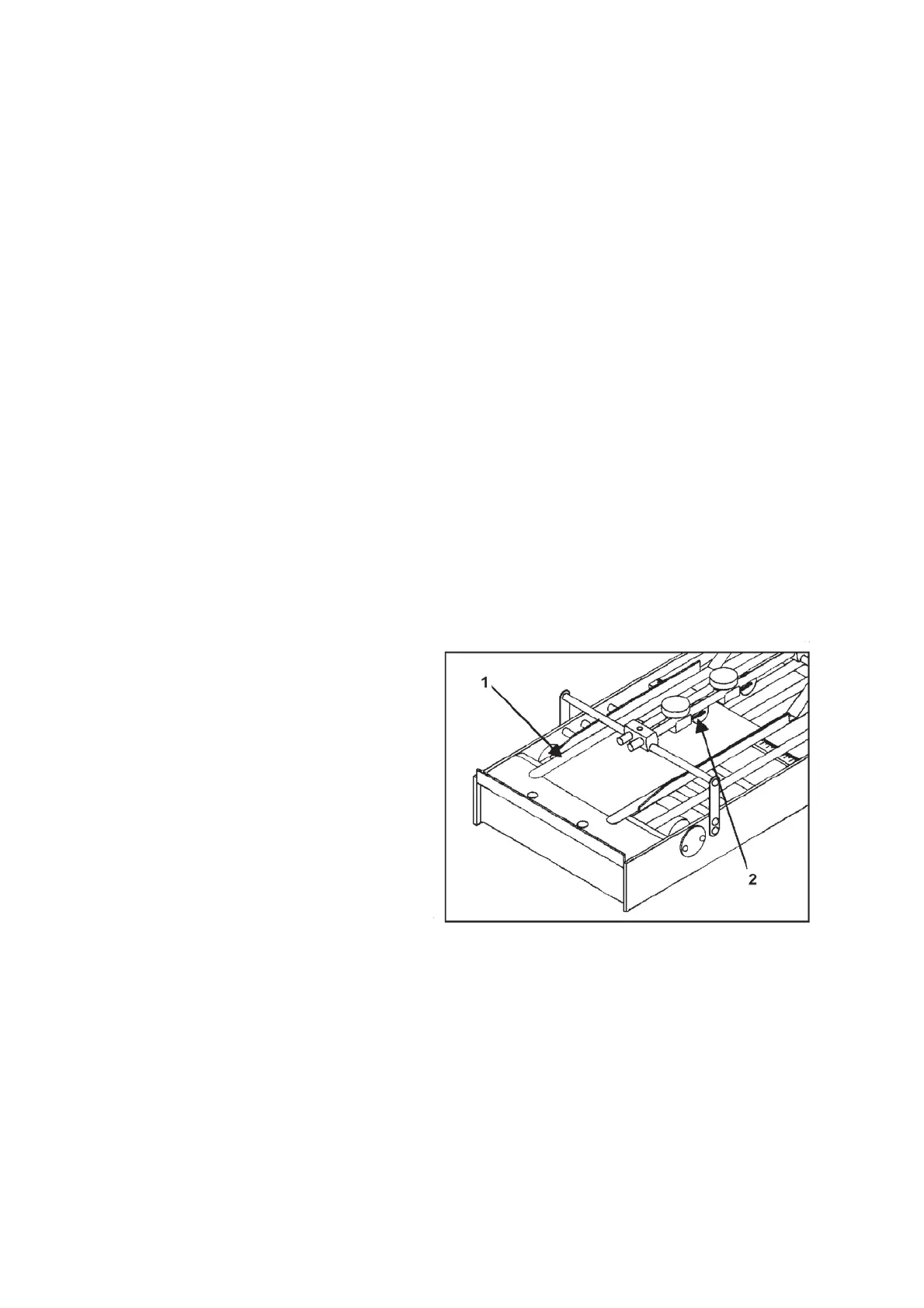

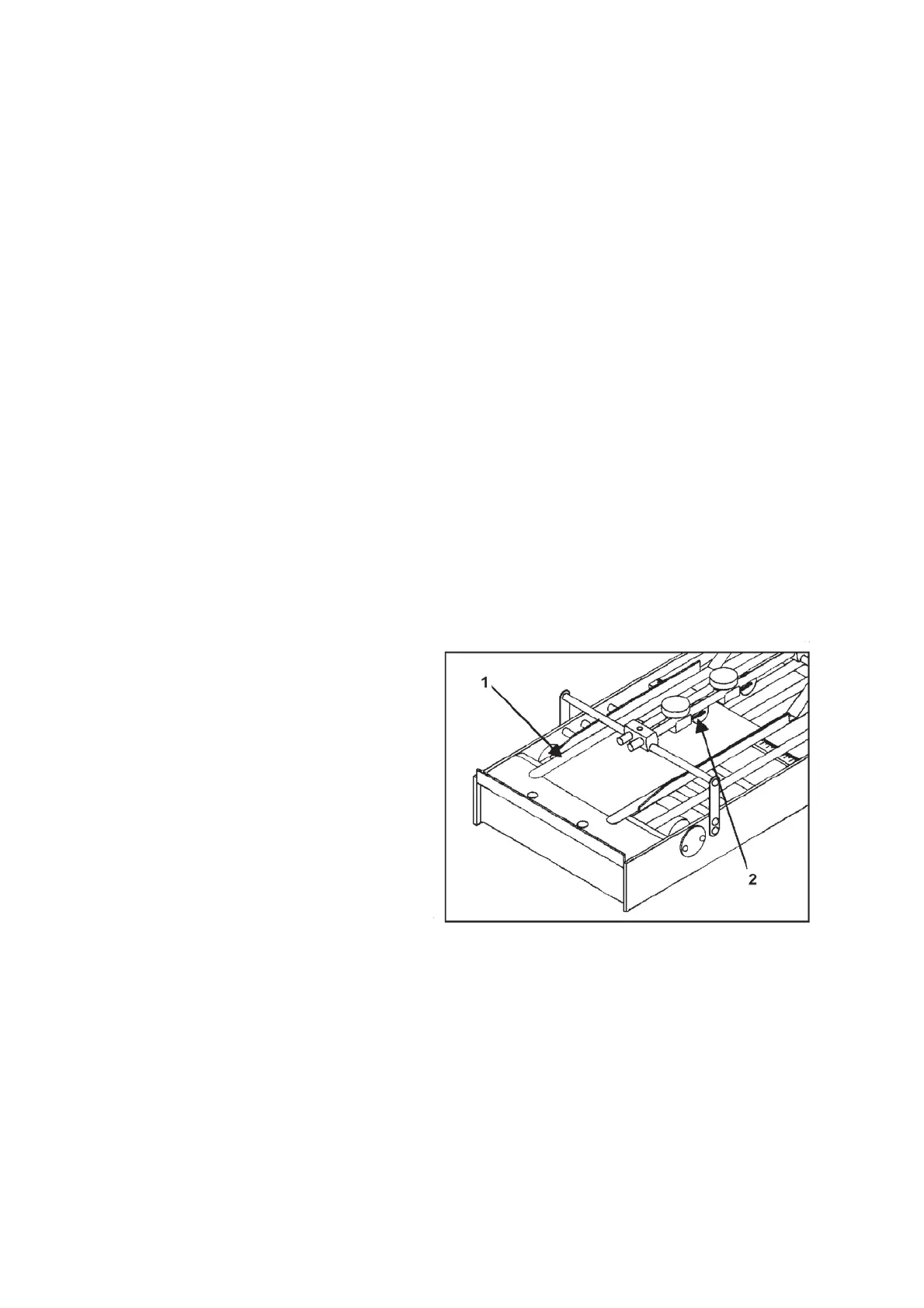

19. Adjust retainer straps [#1, Fig. 10]

over Stop and Push Guide Tapes.

20. When envelope is against Front

Stop Plate, position front skid

wheel [#2, Fig. 9] so it lightly

touches trailing edge of envelope.

21. Turn Press Pump ON.

22. Turn Press Blowers OFF, turn

Press Vacuum Knob to Full.

23. Using Press Hand Wheel; pass

envelope through Press.

NOTE: Make sure envelope

goes into Grippers firmly.

Adjust Buckle Control on

Press if necessary.

24. Set Duplicator on lowest speed.

25. Set Feeder Mode Switch to AUTO position.

26. Turn Feeder Vacuum ON.

Loading...

Loading...