30

Flow direction Figure 9.8.2.b

Fitting the ue

Note: If it is required to cut an extension, DO NOT cut the end of the inner duct that incorporates the seal

joint.

Ensure the inner duct end without the seal joint is cut so that it is ush with the outer duct.

Ensure that all cuts are square and free from burrs.

Once assembled with the components pushed home, the ue is fully sealed.

1. Adjust the telescopic ue and secure with sealing tape supplied or cut the xed length terminal ue to the

required length.

2. Fit the ue to the extensions (if required) by locating the inner duct into the seal joint and push fully home

the inner and outer duct.

3. When connecting the horizontal ue terminal length ensure the terminal end outlet is at the uppermost

part of the ue.

4. Pass the terminal ue assembly through the wall.

5. Fit the bend to the boiler and rotate to the correct position and secure in position.

6. If the inside sealing collar (white) is being used to make good the inside wall, then it will need to be tted

before assembling the ue.

7. Pull the ue assembly towards the bend, locating the inner duct into the seal joint on the bend and secure

the ue assembly to the bend by pushing fully home.

8. Make good the outside wall by tting the outside sealing collar (grey) onto the location provided

immediately behind the ue terminal grille. Make good the inside wall using the inside sealing collar

(white) if required.

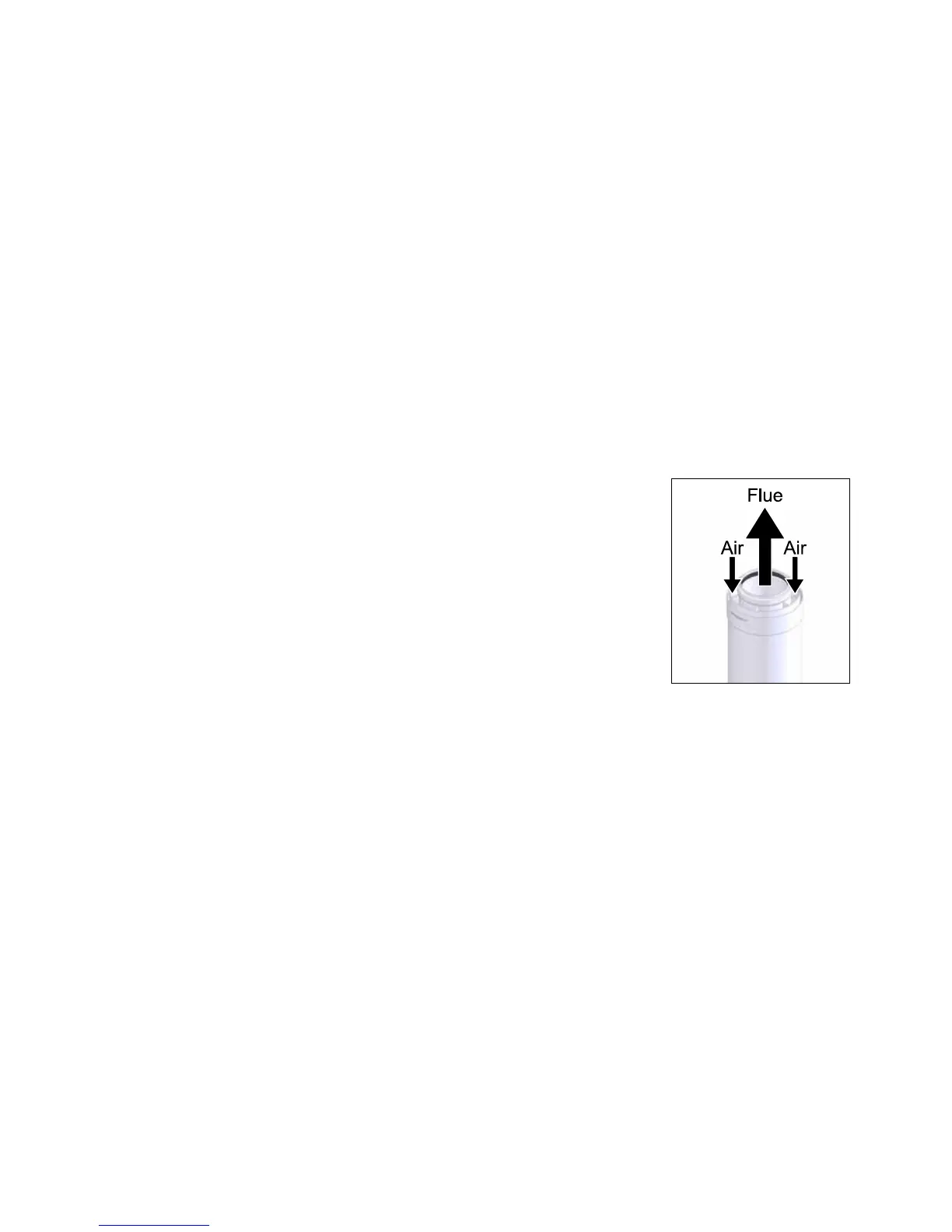

When mounting the ue gas system, pay attention to the ow direction (See

gure 9.8.2.b). It is not permitted to mount a system upside down and will lead to

complaints.

Use a soap solvent or special grease (supplied in the accessory bag with the

boiler) to simplify the tting.

The ATAG ue system used is a push t ue system, which does not require

screws to be tted at each ue joint.

The ue system must be adequately supported at regular intervals between

brackets of no more than 1.0 metres for horizontal sections and no more than

2.0 metres for vertical sections.

Loading...

Loading...