- 49 -

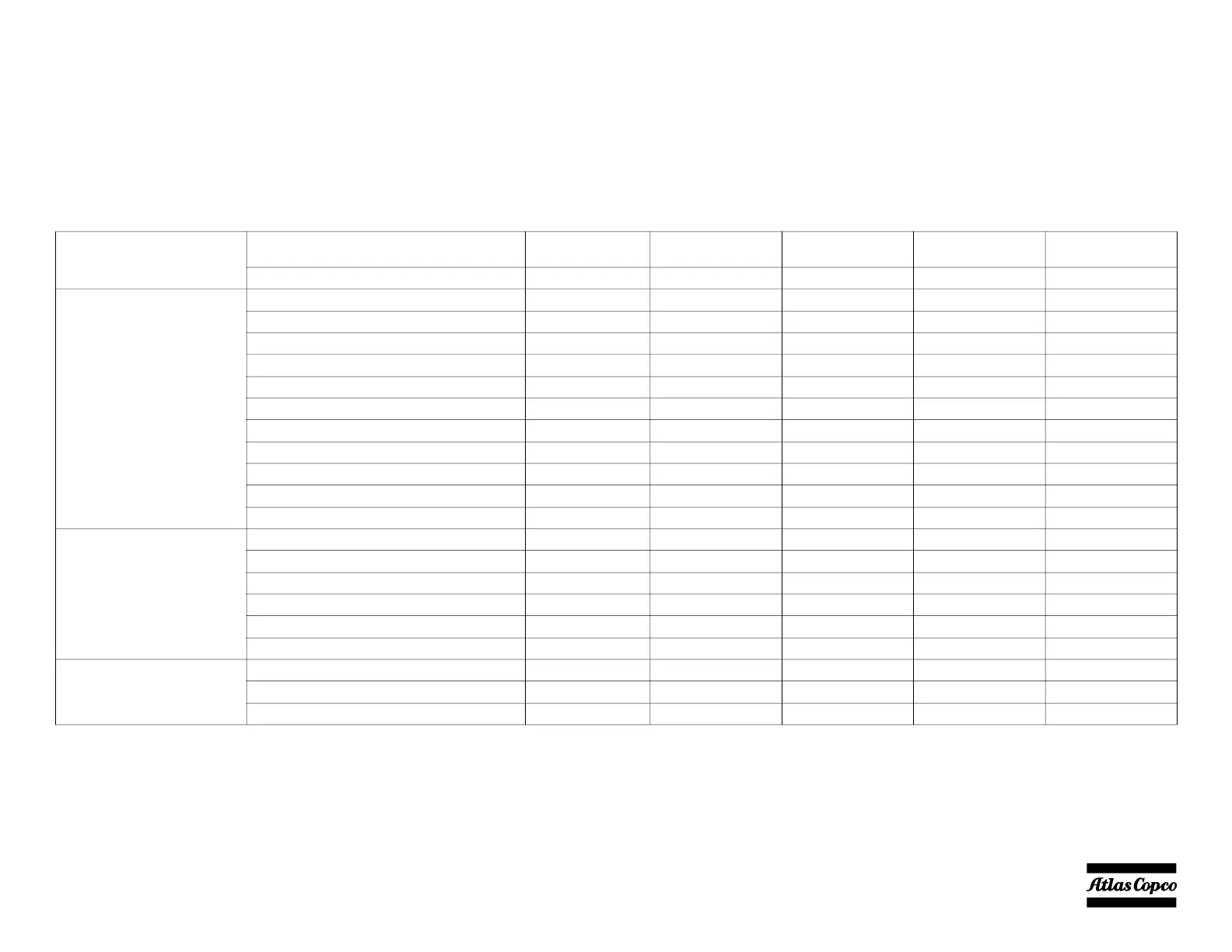

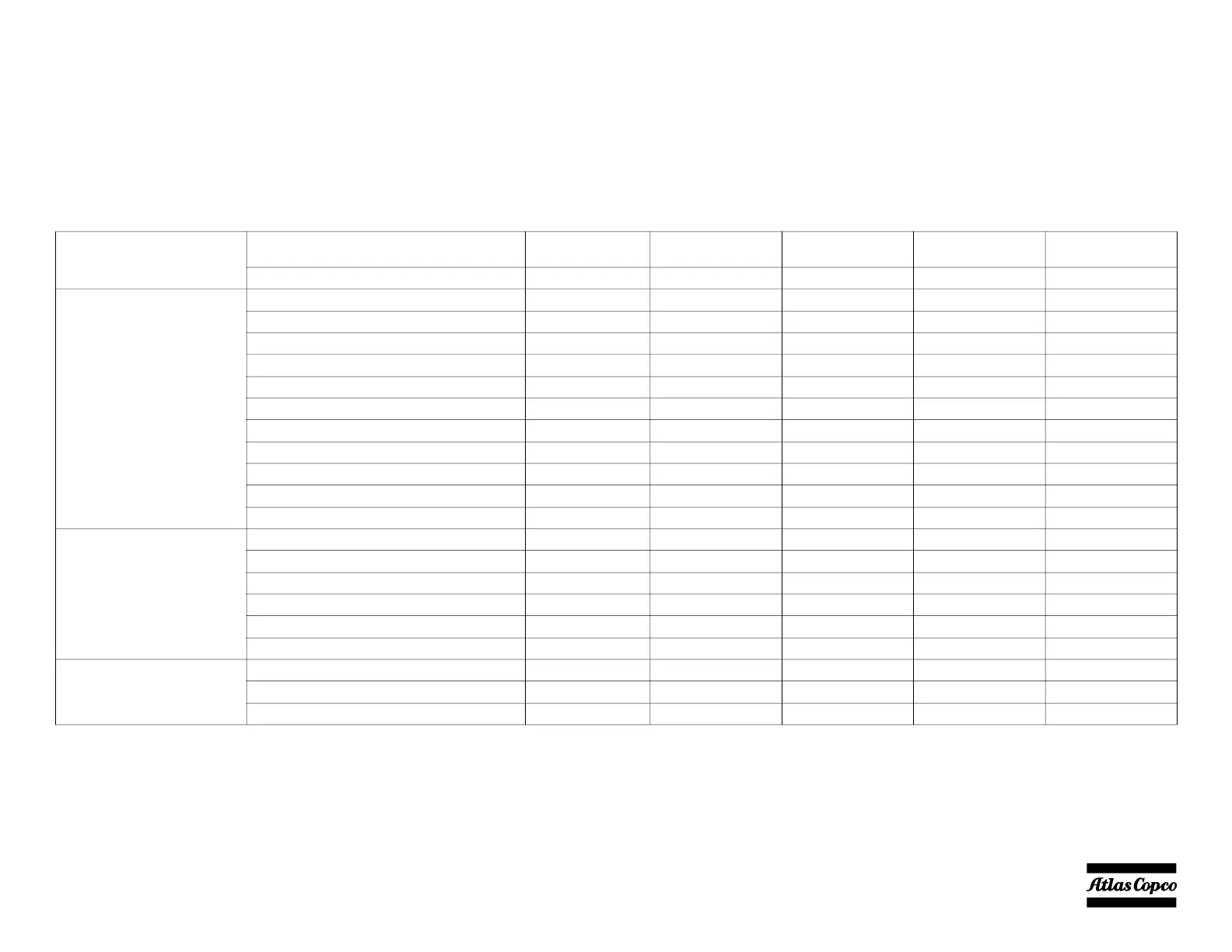

PREVENTIVE MAINTENANCE SCHEDULE

The schedule contains a summary of the maintenance

instructions.

Read the respective section before taking maintenance

measures.

When servicing, replace all disengaged packings, e.g.

gaskets, 0-rings, washers.

For engine maintenance refer to Engine Operation

Manual.

The maintenance schedule has to be seen as a guideline for

units operating in a duty environment typical to

compressor applications. Maintenance schedule can be

adapted depending on application environment and

quality of maintenance.

Maintenance Table Sections

And Sequences

Maintenance Schedule Daily Initial 50hours Every 500 hours /

Half yearly

Every 1000 hours /

2 Yearly

Note

Service Kits : 1310 9233 60 1310 9233 61 1310 9233 62

Daily Operational Checks

Check Fuel Level Check

Check Compressor Oil Level Check

Check Coolant Level Check

Check Fan Belt Check

Fuel Filter Water Drain Empty

Air Filter Dust Valve Empty

Air Intake Vacuum Indicator Check

Air Intake Hose Check

Flexible Hoses Check

Check Tire Pressure Check

Electrolyte Level And Terminals Of Battery Check Check Check

Roading Equipment Checks

Jack Stand Check

Torque Wheel Nuts Check Check Check

Inspect Tires for Cuts or Damage Check

Service Wheel Bearings Inspect

Safety Chains Check Check

Safety Decals Condition Check Check

Safety Equipment Checks

Inspect Safety Valve Operation Check

Inspect Shutdown switch operation Check

Leaks in Air, Oil or Fuel System Check Check Check

Loading...

Loading...