Once a month unscrew the filler

caps and pour a small quantity 01

di.tilled water into each01 the cells

to bring the acid just level with the

tops of the separators.

Distilled water can be obtained

Irom any chemist and most garages.

Do not use tap water, as it contains

impurities detrimental to the battery.

If any acid is accidentally spilled

from the battery, it must be replaced

B' by a dilute sulphuric acid solution

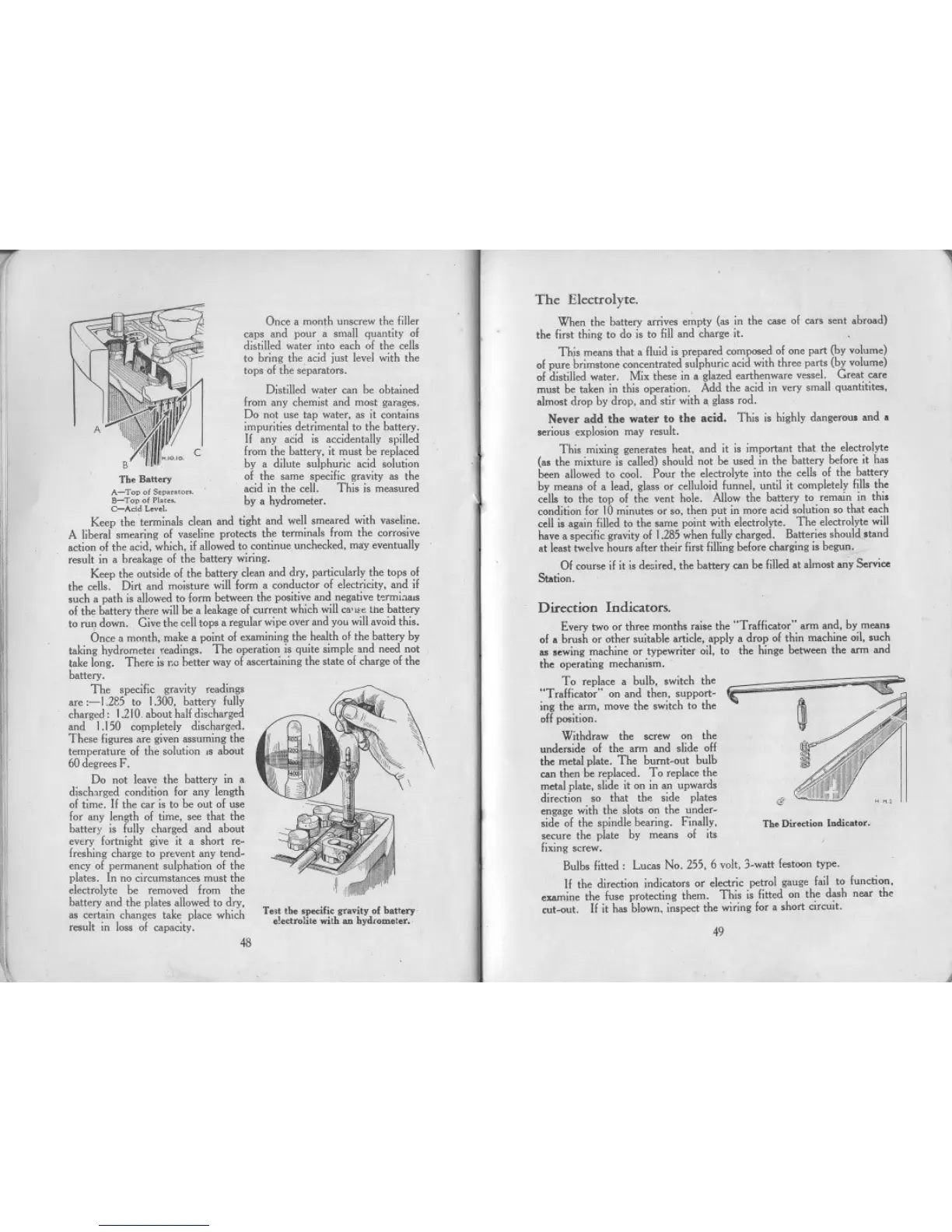

The Battery of the same specific gravity as the

A-Top ofS,p.,,<on. acid in the cell. This is measured

B-Top ofPI"" by a hydromeier.

C-Add Lml.

Keeptheterminals clean and tight and well smeared with vaseline.

A liberal smearing 01 vaseline protects the terminals Irom the corrosive

action 01the acid, which, if allowed to continue. unchecked, mgy eventually

result in a breakage 01 the battery wiring.

Keep the outside 01 the battery clean and dry, particularly the tops 01

the cells. Dirl and moisture will form a conductor of electricity, and il

such a path is allowed to lorm between the positive and negative t"mic,als

01the battery there will be a leakage 01current which will ca"'e the battery

to run down. Give the cell tops a regular wipe over and you will avoid this.

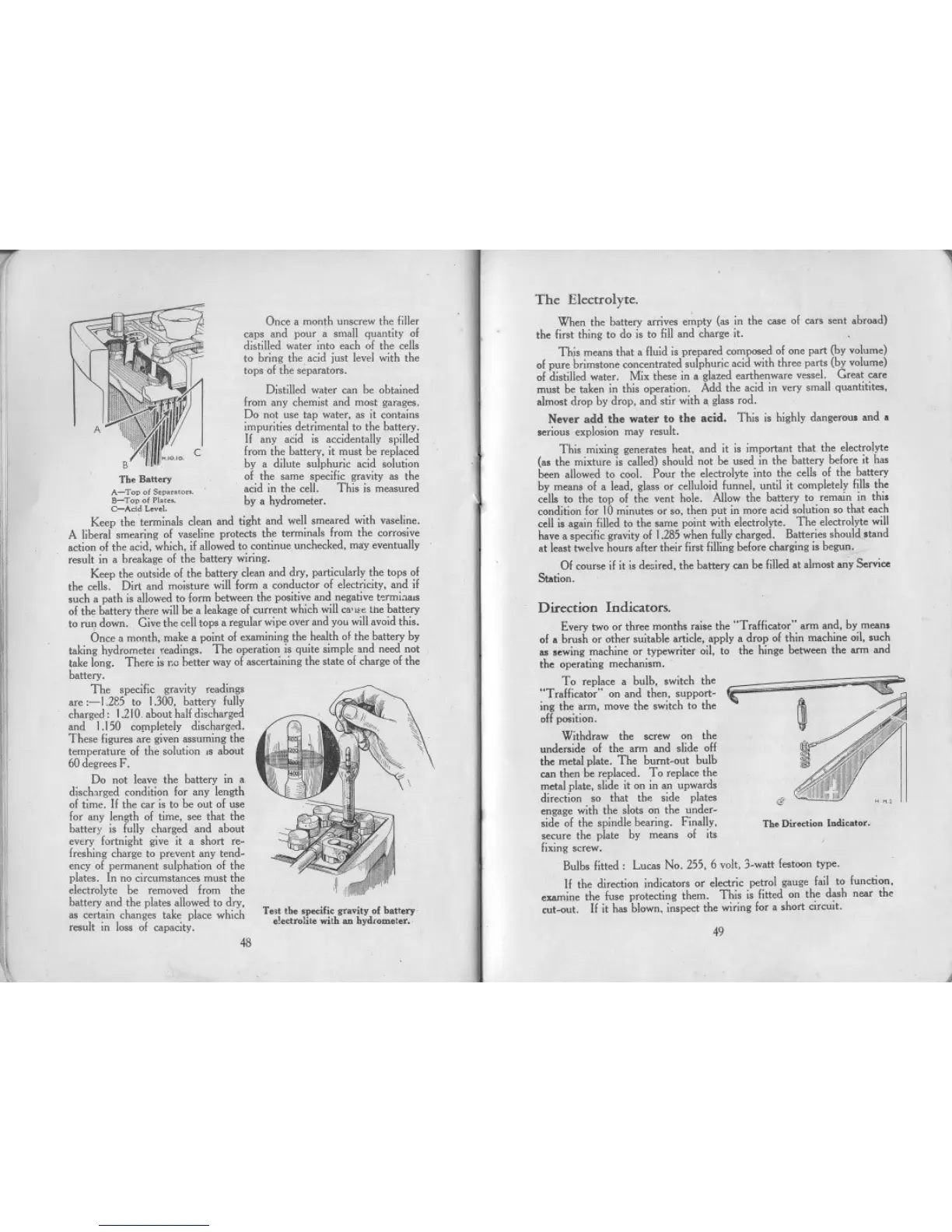

Once a month, make a point 01examining the health of the battery by

taking hydrometer readings. The operation is quite simple and need not

take long. There is r.o better way of ascertaining the state of charge of the

battery .

The specific gravity readings

are :-1.285 to 1.300, battery lully

charged: 1.210.about hall discharged

and 1.150 cOJ1lpletely discharged.

These figures are given assuming the

temperature 01 the solution ISabout

60 degrees F.

Do not leave the battery in a.

discharged condition for any length

of time. If the car is to be out 01 use

lor any length of time, see that the

battery is fully charged and about

every lortnight give it a short re-

Ireshing charge to prevent any tend-

ency 01 permanent sulphation of the

plates. In no circumstances must the

electrolyte be removed Irom the

battery and the plates allowed to dry,

as certain changes take place which Test the specif~cgravity of hattery

result "n I

I

.

t

e!ectroh'e wJlh an hydrometer..

oss 0 capaCI y.

48

..,..

I

i

,I

I

!I.

III

H

1

1

il

('I

"

The Electrolyte.

When the battery arrives e~pty (as in the case 01 cars sent abroad)

the lirst thing to do is to fill and charge it.

This means that a fluid is prepared composed of one part (by volume)

of pure brimstone concentrated sulphuric acid with three parts (by volume)

01 distilled water. Mix these in a glazed earthenware vessel. Great care

must be taken in this operation. Add the acid in very small quantitites,

almost drop by drop, and stir with a glass rod.

Never add the water to the acid. This is highly dangerous and a

serious explosion may result.

This mixing generates heat, and it is importgnt that the electrolyte

(as the mixture is called) should not be used in the battery before it has

been allowed to cool. Pour the electrolyte into the cells 01 the battery

by means of a lead, glass or celluloid funnel, until it completely fills the

cells to the top 01 the vent hole. Allow the battery to remain in this

condition for 10 minutes or so, then put in more acid solution so that each

cell is again lilled to the same point with electrolyte. The electrolyte will

have a specilic gravity 011.285 when lully charged. Batteries should stand

at least twelve hours alter their first filling belore charging is begun.

01 course if it is de:;ired. the battery can be filled at almost any Service

Station.

Direction Indicators.

Every two or three months raise the uTrafficatorU arm and, by means

01a brush or other suitable article, apply a drop 01 thin machine oil, such

as sewing machine or typewriter oil, to the hinge between the arm and

the operating mechanism.

To replace a bulb, switch the

uT rafficator" on and then, support-

ing the arm, move the switch to the

off position.

Withdraw the screw on the

underside of the arm and slide 011

the metal plate. The burnt-out bulb

can then be replaced. To replace the

metalplate, slide it on in an upwards

direction so that the side plates

engage with the slots on the under-

side of the spindle bearing. Finally,

secure the plate by means of its

lixing screw.

Bulbs fitted: Lucas No. 255, 6 volt, 3-watt festoon type.

If the direction indicators or electric petrol gauge lail to function,

examine the fuse protecting them. This is litted on the dash near the

cut-out. If it has blown, inspect the wiring for a short circuit.

\ ~ <:

c?

""'

The Direction Indicator.

49

..j

Loading...

Loading...