4

Maintenance And Checks

It is recommended that users refer to the following standards to carry out regular inspections

and maintenance to maintain the best condition of the aircraft and reduce potential safety

hazards.

Deep cleaning, component

inspection, calibration

Recommended to return

to factory or contact Autel

Robotics authorized dealer

Frequency decided by

user based on usage

Deep cleaning, component

inspection, calibration,

replacement of wearing

parts

Every 300 flight hours

or every year

Deep cleaning, component

testing, calibration,

replacement of wearing

parts, power system

replacement

Every 900 flight hours

or every 3 years

*Maintenance Cycle or flight time is whichever comes first.

*Time stated (every year or every 3 years) is noted as the time since activation.

For different regions, Autel Robotics may adjust the maintenance type and cycle. For the latest

service details, please consult your local dealer or Autel Robotics After-Sales team

Component Inspection

Power System

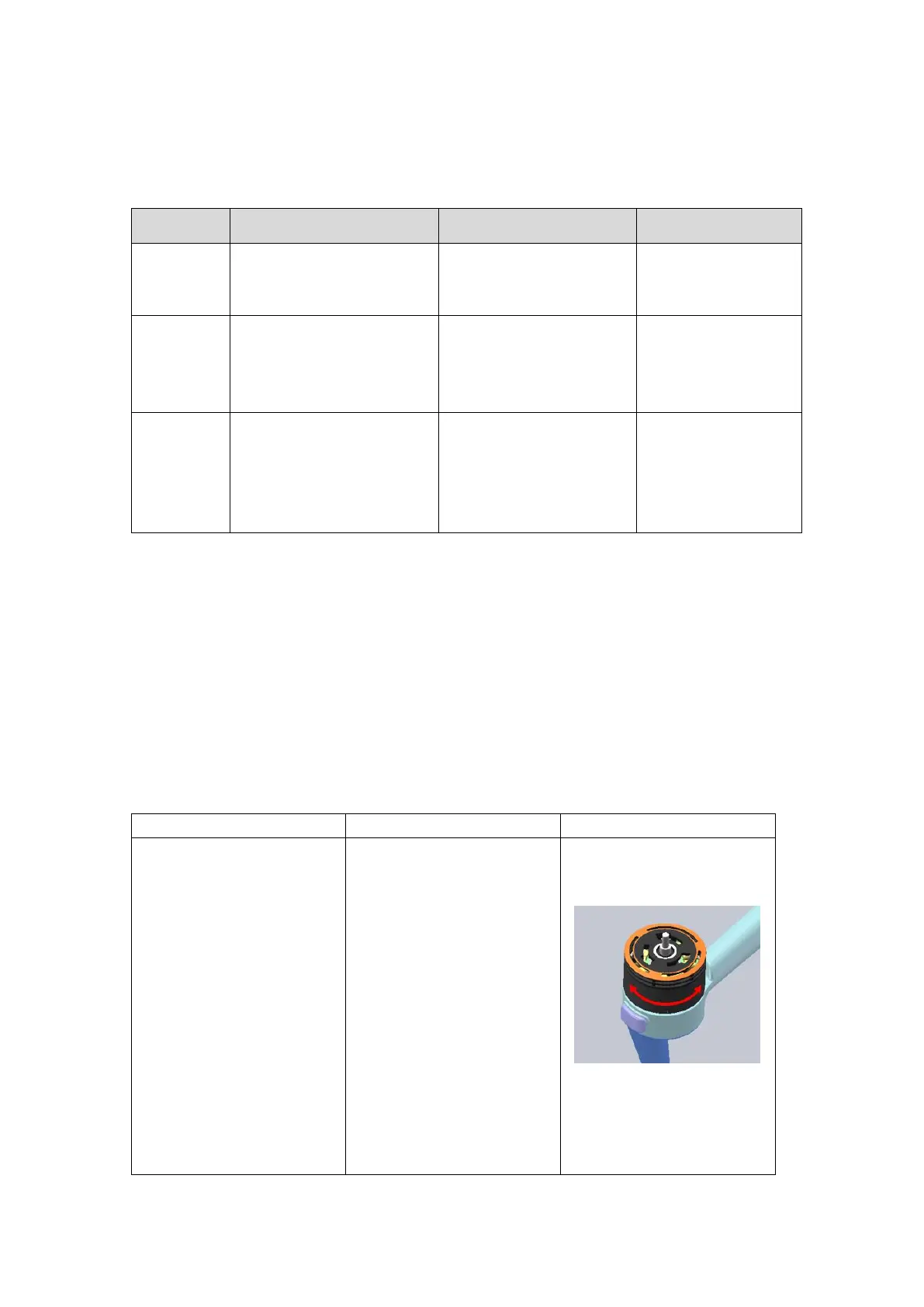

2. Remove the propeller

and visually check for

foreign objects in the

inner chamber of the

rotor, clean carefully as to

not scratch the coils.

3. Rotate the motor to

check whether there is

any jamming, scratching

or odd sounds. Visually

inspect the motor and

base to check for foreign

objects;

Loading...

Loading...