OM-261 661 Page 8

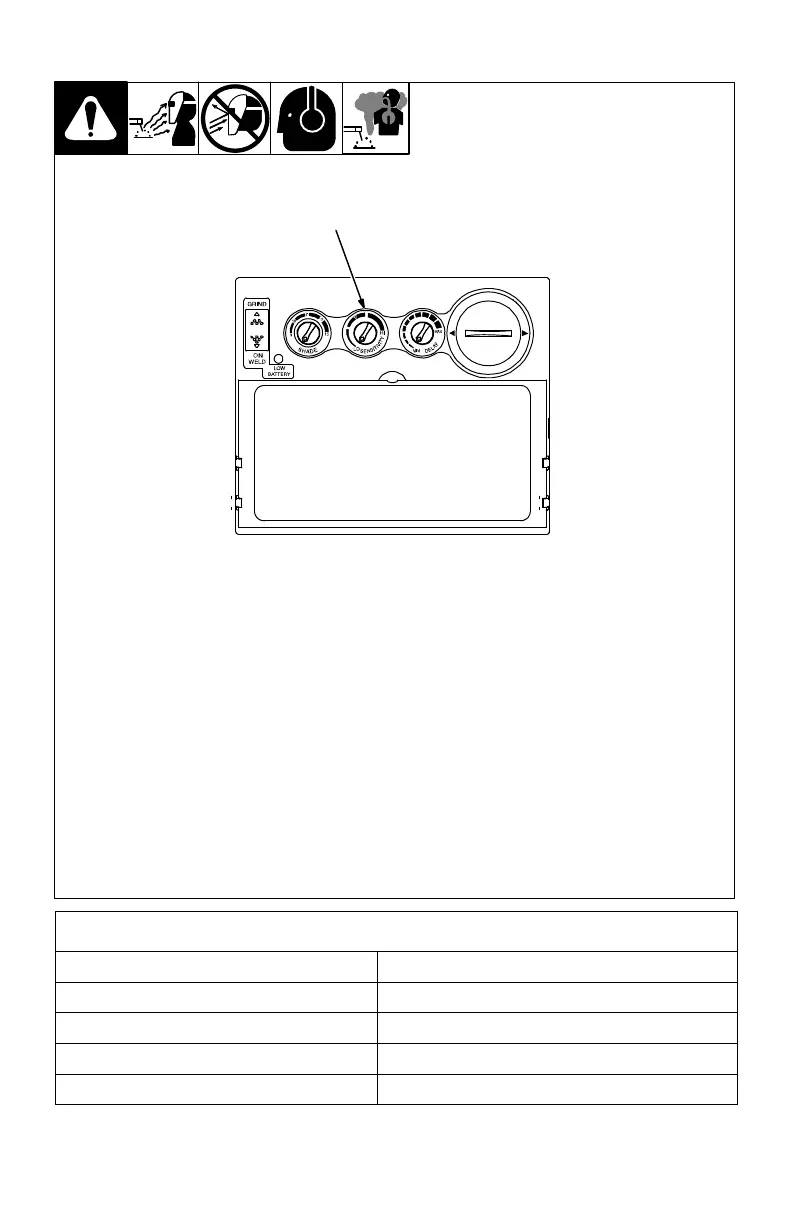

3-6. Sensitivity Control

1 Sensitivity Control

Use control to make the

lens more responsive to dif-

ferent light levels in various

welding processes. Use a

Mid-Range or 30−50%

sensitivity setting for

most applications.

It may be necessary to ad-

just helmet sensitivity to ac-

commodate different light-

ing conditions or if lens is

flashing On and Off. Adjust

helmet sensitivity as fol-

lows:

Adjust helmet sensitiv-

ity in lighting conditions

helmet will be used in.

Turn sensitivity control

to lowest setting.

Face the helmet in the

direction of use, expos-

ing it to the surrounding

light conditions.

Gradually turn sensitiv-

ity setting clockwise

until the lens darkens,

then turn sensitivity

control counterclock-

wise until slightly past

setting where lens

clears. Helmet is ready

for use. Slight readjust-

ment may be neces-

sary for certain ap-

plications or if lens is

flashing on and off.

1

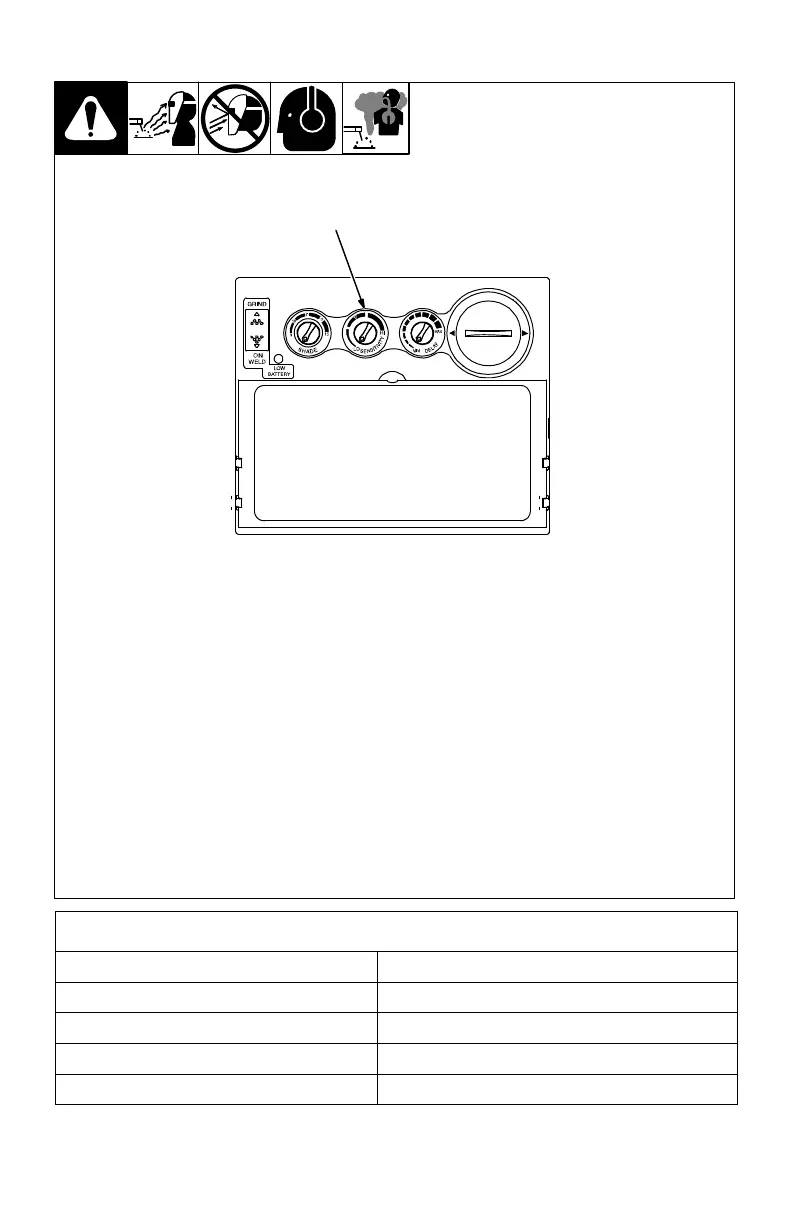

Recommended Sensitivity Settings

Stick Electrode Mid-Range

Short Circuiting (MIG) Low/Mid-Range

Pulsed & Spray (MIG) Mid-Range

Gas Tungsten Arc (TIG) Mid/High-Range

Plasma Arc Cutting/Welding Low/Mid-Range

Loading...

Loading...