24 5

• Valid Automotive Electrical System Testing depends on all

the components being in good operating condition. In

addition,thebatteryMUSThavesufcientchargefortesting.Carefully

perform the following steps before attempting any electrical diagnosis.

• Inspect Belts for cracks, glazed surface and fraying. Most late model

vehicles use an automatic belt tensioner. Tighten loose belts, or replace a

faulty belt tensioner.

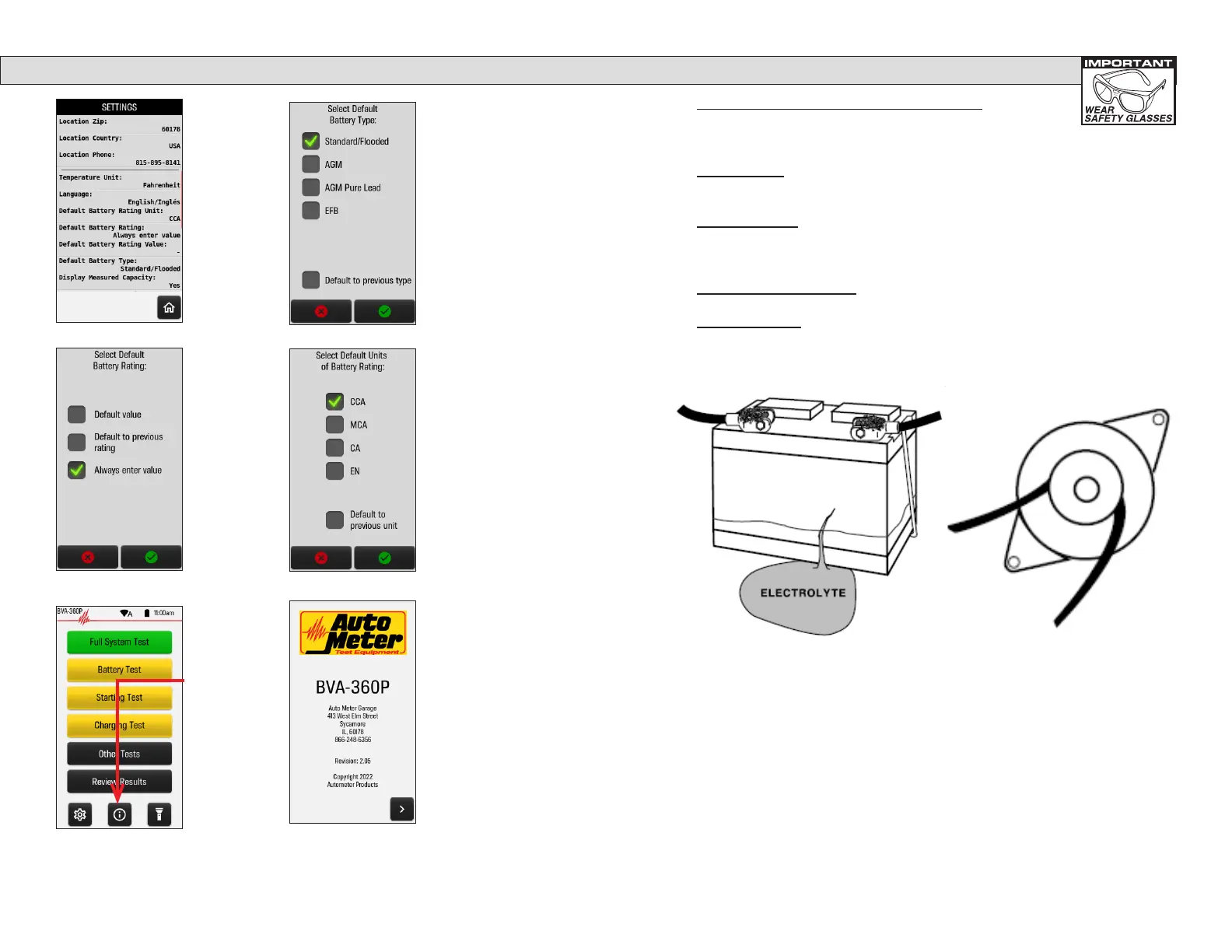

• Inspect Battery for terminal corrosion, loose or broken posts, cracks in the

case, loose hold-downs, low electrolyte level, moisture, and dirt around the

terminals. Attempt to charge a dead battery prior to testing (a frozen battery

mustbethawedrst!).

• Inspect Starting System. Check starter, solenoid, and regulator for loose

connections, loose mounts and frayed or cracked wires.

• Important Note: A damaged battery must be replaced before proceeding.

Check for leaks, If no leaks are

present, top off with water, if

serviceable.

Correct loose or dirty battery terminal

Correct loose or low tension

alternator belt.

INSPECTION

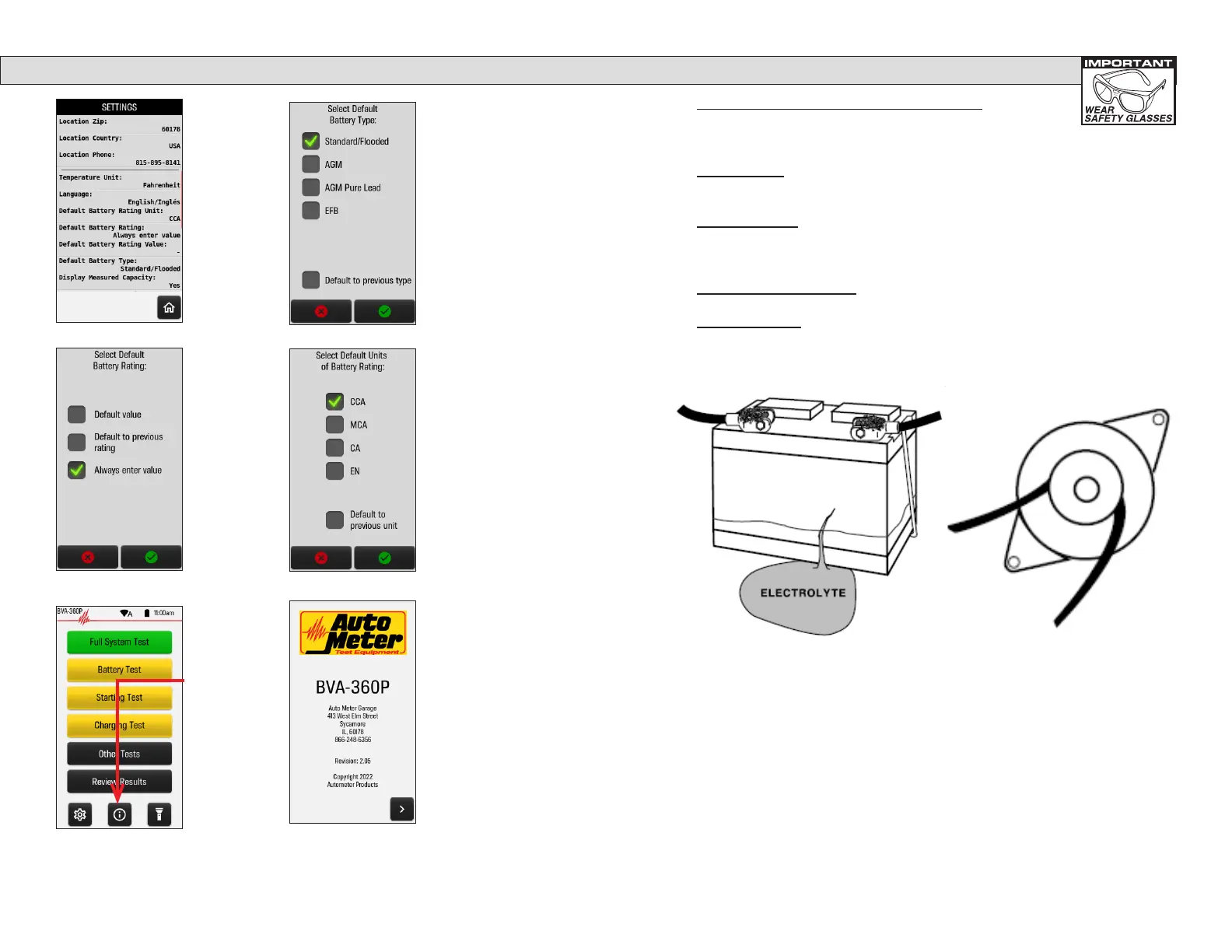

SETTINGS & UNIT INFORMATION

Example: Here

you can change the

battery test defaults

to suit your needs,

by touching the

appropriate setting to

modify.

To display Unit

Info, touch

the icon in the

middle lower

part of the

screen.

Example of the

Unit Info page.

Loading...

Loading...