AUTOMATOR INTERNATIONAL SRL – Via Meucci n.8–20094 Corsico (Mi) Italia

Tel 02 48601445 Fax 02 48601503 e-mail info@automator.com www.automator.com

Tel 02 48601445 Fax 02 48601503 e-mail info@automator. Com www.automator.com

Tel 02 48601445 Fax 02 48601503 e-mail info@automator. Com www.automator.com

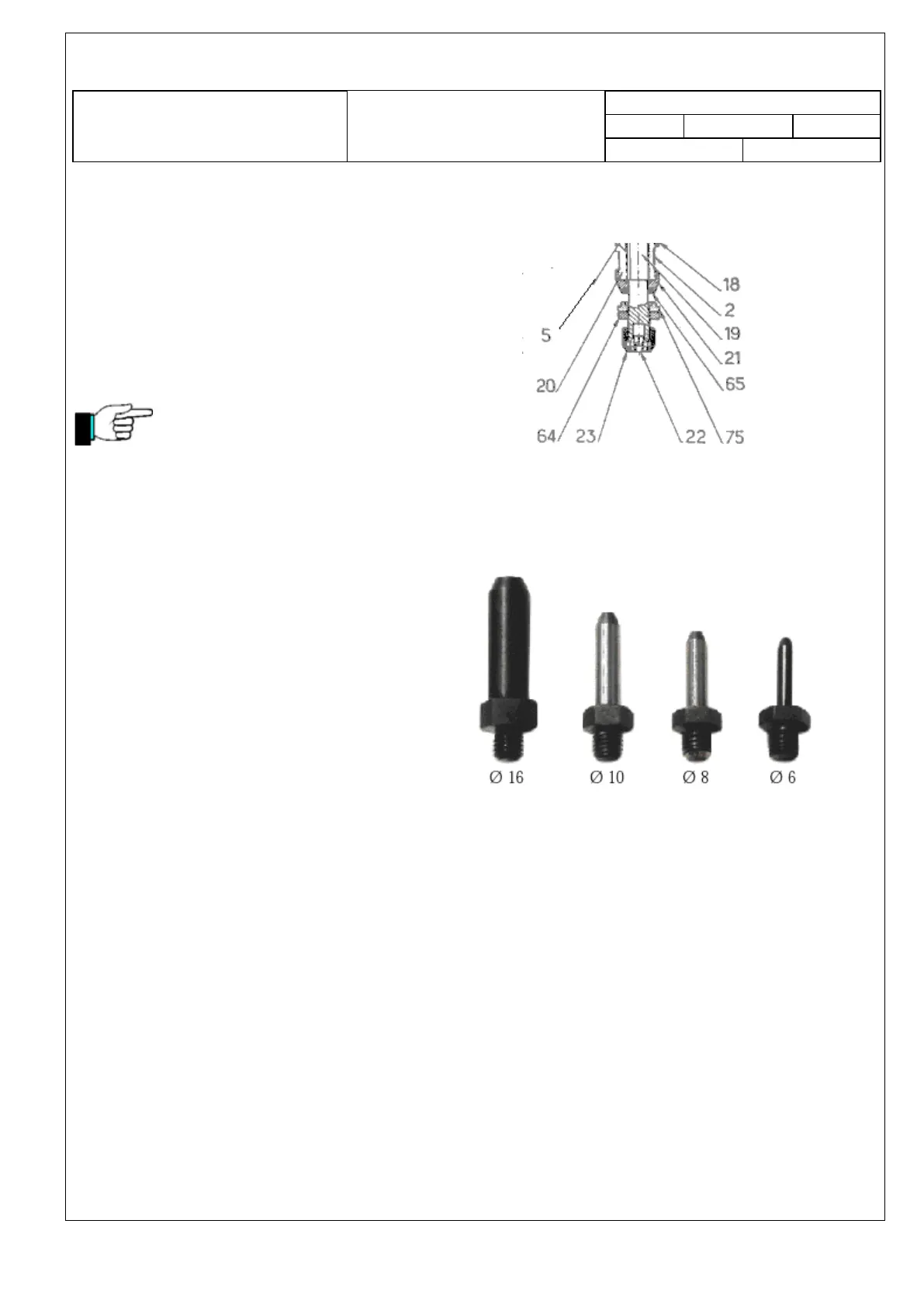

To insert the type-holder or any other marking head,

loose the collet nut (Ref.23) e insert the shank with

the adequate diameter trough the above-mentioned

nut, which closes the collet (Ref. 22) e the ram anvil

(Ref.19). Once positioned the type-holder, tighten up

firmly the collet nut (Ref.23) to keep the marking

head in the desired alignment. The distance

between the shank and the collet nut must be about

1 o 2 mm.

Do not use hammers or other similar objects to

insert or secure the type-holder; in this case,

damages to the ram anvil or to the nut may occur

Note : Use only original shanks to avoid damages to

the ram anvil (ref. 19) or collet nut (Ref. 23)

If You do not use original Automator shank, when

screwing the collet nut, you can break the collet

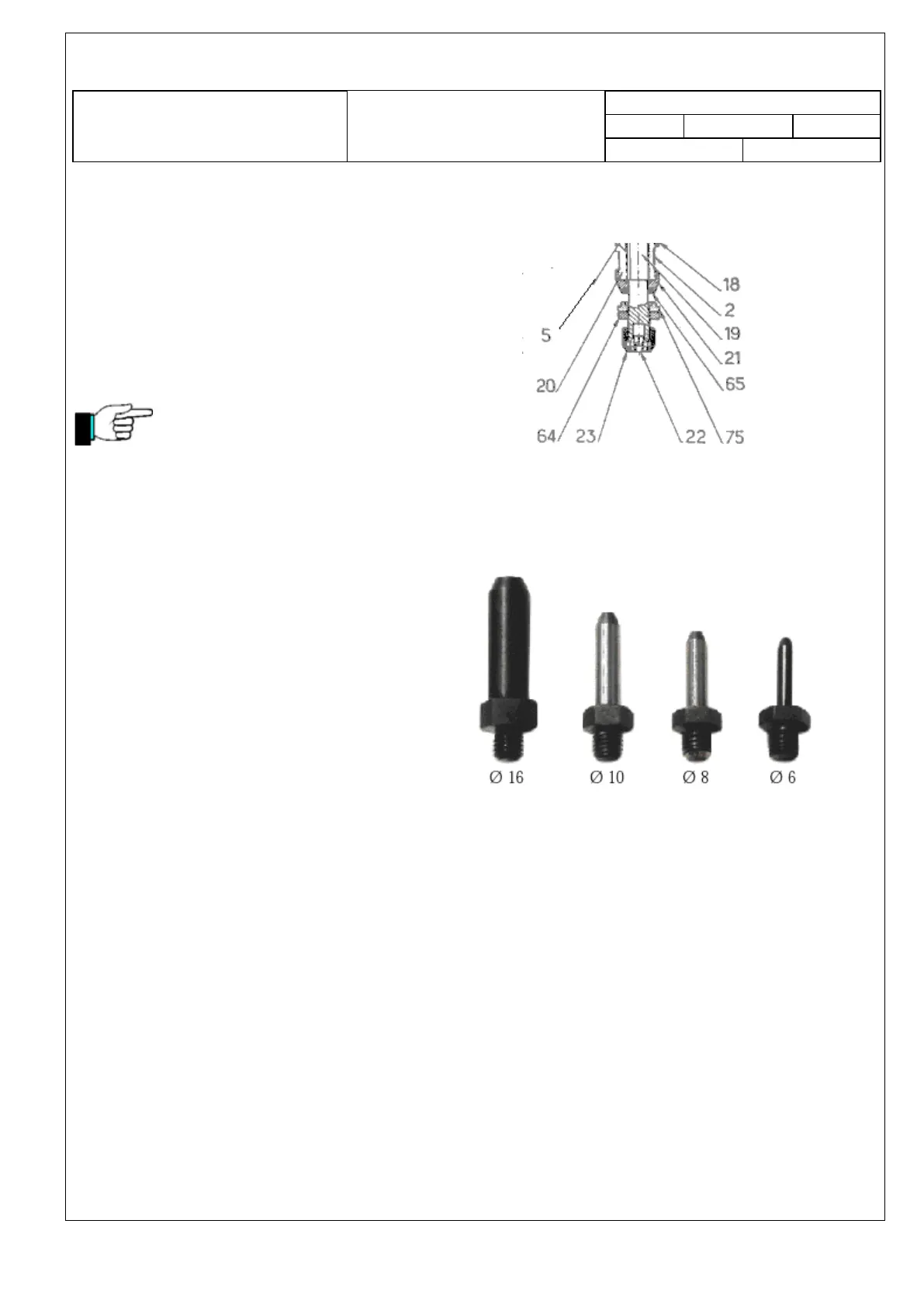

The shank should move easily through the collet,

but there should be no play. The sizes of the shanks

for the different unit models are as follows :

MB19VPN – 8mm

MB21VP – 10mm

MB35VP – 16mm

Do not block the ram anvil (Ref. 19) exaggerating in the locking of the key retaining nut (measure 6)

The unit will not operate unless the ram anvil (Ref. 19) moves freely and smoothly. In the axial sense,

it is suggested a tolerance from 3 to 5/10.

Please note that the impact force comes from the centre of the tool holder (Ref.19) and type holders or

any tooling should not make contact with the collet nut (Ref.23) when in operation.

Loading...

Loading...