Major Products

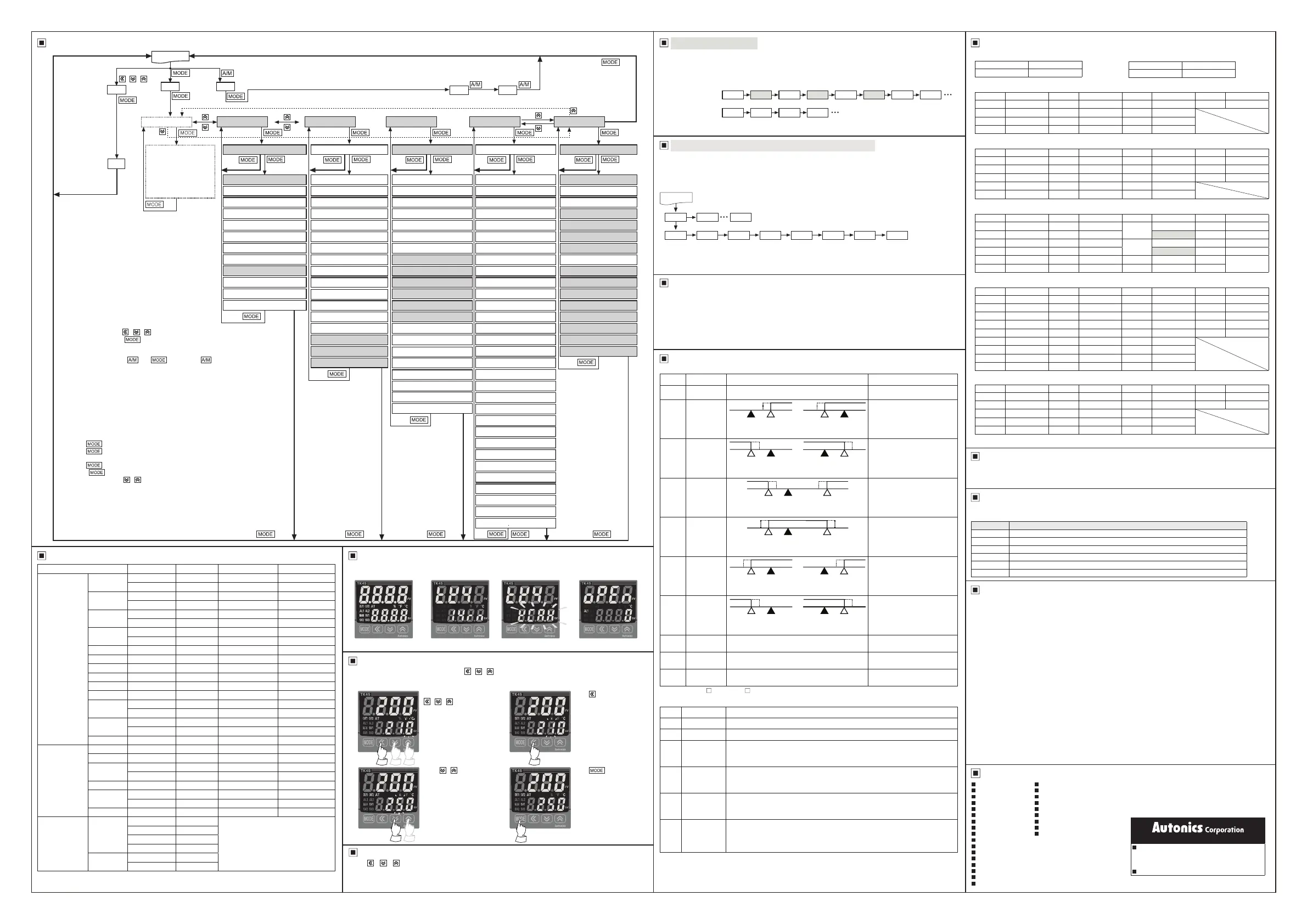

Flow Chart for Setting Group Parameter Mask

User Manual

Comprehensive Device Management Program[DAQMaster]

Cautions during Use

Factory Default

User Parameter Group [

PARU

] Setting

Auto-tunning

Alarm

Input Types and Range Initial Display When Power ON

Set Value (SV) Setting

Multi SV Number[

SV-N

]

Control output RUN/STOP[

R-5

]

PARU

※

3

PAR1 PAR2 PAR3 PAR4 PAR5

Set user parameters

in DAQMaster

SV

PASS

※

1

※

1

※

1

※

2

C-MVH-MV

※

2

※

2

When PW is valid

Set the

set value

When PW

is valid

Press any key among

, , once.

SV will be automatically

saved after 5 sec.

※

1.

PASS

parameter will be displayed only when password is set.

It is not displayed when purchasing the unit since default

password is set to

0000

.

If password is not valid, the screen will be shifted to password

code required window.

Press any key among , , to return to password

entering window. Press key to return to RUN mode.

In case you forget password, contact Autonics after checking

password code.

※

2. TK4N/S/SP do not have

key. key replaces key.

※

3. It is displayed when setting user parameter group

in the integrated device management program (DAQMaster).

When power is supplied, whole display parts ash for 1 sec. Afterwards, model name and input sensor type

will be ash twice and then in enters into RUN mode.

※

1: C (TT): Same temperature sensor as former W5 (TT)

※

2: G (TT): Same temperature sesnor as former W (TT)

You can set the temperature to control with

, ,

keys.

Set range is within SV low-limit value [

L-SV

] to SV high-limit value [

H-SV

].

Ex) In case of changing set temperature from 210

℃

to 250

℃

Press any key among

, ,

in RUN mode

to enter into SV setting

mode.

Last digit (10

0

digit) on

SV display part ashes.

※

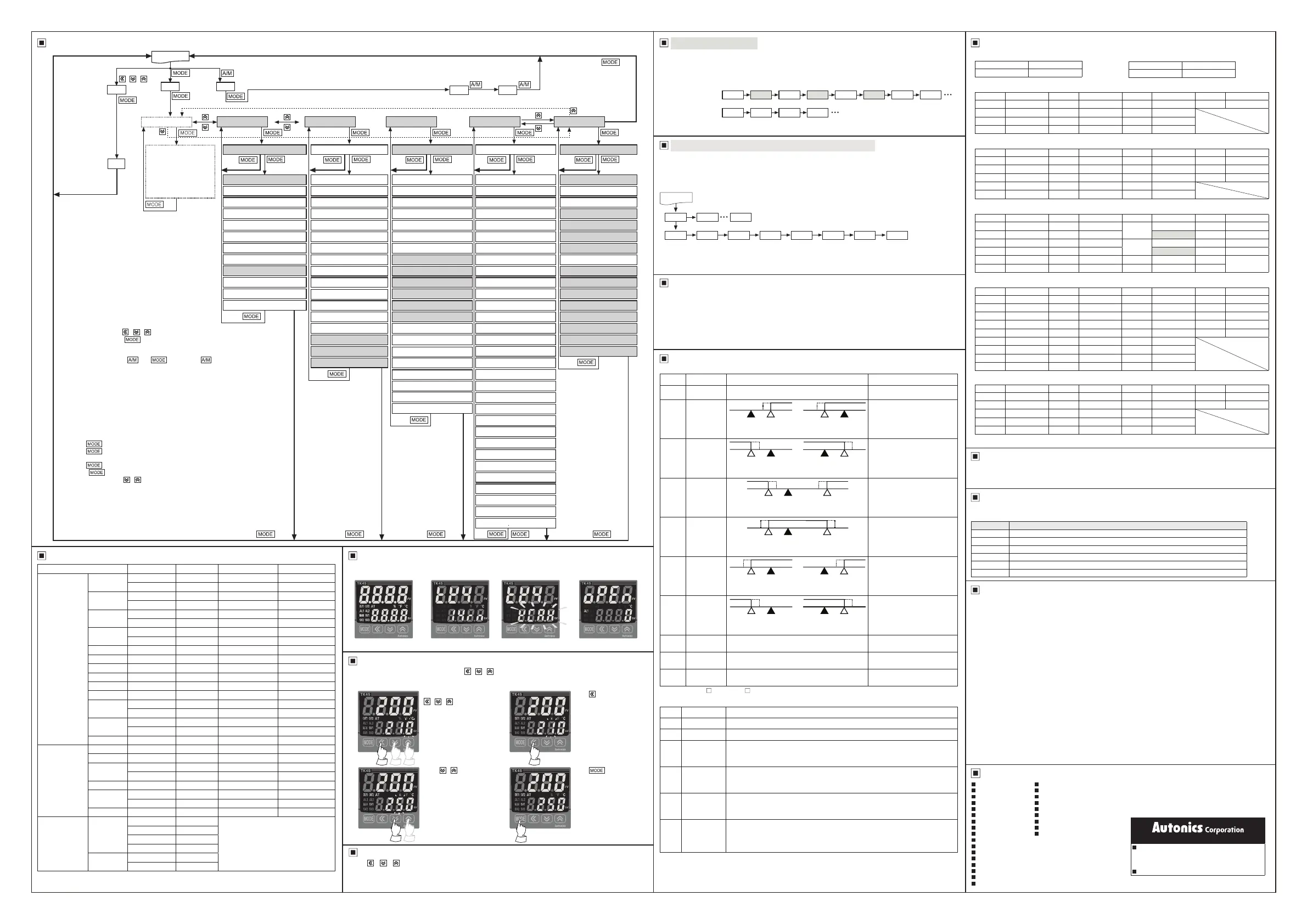

Condition of re-applied standby sequence for standby sequence 1, alarm latch and standby sequence 1: Power ON

Condition of re-applied standby sequence for standby sequence 2, alarm latch and standby sequence 2: Power ON,

changing set temperature, alarm temperature [

AL1

,

AL2

] or alarm operation [

AL-1

,

AL-2

], switching STOP mode

to RUN mode.

※

H: Alarm output hysteresis[

A .HY

]

※

Shaded parameters are for the heating&cooling model.

●Alarm option

●Alarm operation

Press

,

key to raise

or lower the set value.

Press key to move digit.

(10

0

→ 10¹→

10²→10³→ 10

0

)

Press

key to save

the set value.

If there is no additional

key operations in 3 sec,

the changed SV is

automatically saved.

※

Hold the key over 2 sec in RUN mode to enter into setting mode.

※

Hold the key for 1.5 sec while in setting mode to move to other

parameter group.

※

Hold the key over 3 sec while in setting mode to return to RUN mode.

※

Press the key at the lowest level of parameter to move parameter

group screen and press , key to move to other parameter group.

※

If there is no additional key operation within 30 sec after entering into setting

mode, it will be automatically returned to RUN mode and previous set value

will be remained.

※

The not-shaded parameters may not be displayed by other parameters

setting, parameter mask setting.

This function is able to hide unnecessary parameters to user environment or less frequently used parameters in

parameter group. You can set this in the integrated device management program (DAQmaster).

Masked parameters are not only displayed. The set value of masked parameters are applied.

For more information, refer to the DAQMaster user manual.

Visit our website (www.autonics.com) to download the DAQmaster program and the user manual.

For the detail information and instructions, please refer to user manual and user manual for communication,

and be sure to follow cautions written in the technical descriptions (catalog, homepage).

Visit our homepage (www.autonics.com) to download manuals.

DAQMaster is a comprehensive device management software for setting parameters and monitoring

processes. DAQMaster can be downloaded from our website at www.autonics.com.

Parameter Factory default

SV 0

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

R-S RUN AL!H 1550 AL#H 1550 SV-3 0000

SV-N SV-0 AL@L 1550 SV-0 0000

CT-A )0 AL@H 1550 SV-1 0000

AL!L 1550 AL#L 1550 SV-2 0000

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

AT OFF H-D 0000 hOST 000 RAMU 000

H-P 01)0 C-D 0000 cHYS 002 RAMD 000

C-P 01)0 DB 0000 cOST 000 rUNT MIN

H-I 0000 REST 05)0 L-MV `0)0

C-I 0000 hHYS 002 H-MV 10)0

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

IN-T KCaH H-SC 10)0

O-FT

HEAT O!SR STND

UNIT ?C dUNT ?/O H-C O!MA 4-20

L-RG 0)00 IN-B 0000

C-MD

PID OUT2 CURR

H-RG 1)00 MAvF 00)1 pP O@MA 4-20

DOT )0 L-SV -200 AtT TUN1 H-T

02)0

(Relay)

00@0

(SSR)

L-SC 00)0 H-SV 1350 OUT1 CURR C-T

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

AL-1 DVCC A@N NO LBaT 0000 BPS 96

AL!T AL-A A@ON 0000 LBaB 002 PRTY NONE

A!HY 001 A@OF 0000 AoM1 PV STP 2

A!N NO AL-3 OFF FsL1 -200 RSWT 20

A!ON 0000 AL#T AL-A FsH1 1350 COMW EnA

A!OF 0000 A#HY 001 AoM2 PV

AL-2 ]]DV A#N NO FsL2 -200

AL@T AL-A A#ON 0000 FsH2 1350

A@HY 001 A#OF 0000 ADRS 01

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

Parameter

Factory default

MtSV 1 PrMV 00)0 LcSV OFF LcPS OFF

DI-K STOP ErMV 00)0 LcP1 OFF PWD 0000

DI-1 OFF StMV 00)0 LcP2 OFF

DI-2 OFF StAL CONT LcP3 OFF

ItMV AUTO USER STND LcP4 OFF

Parameter Factory default

PASS 0001

This function is able to set the frequently used parameters to the user parameter group. You can quickly and

easily set parameter settings. User parameter group can have up to 30 parameters in the integrated device

management program (DAQMaster).

For more information, refer to the DAQMaster user manual.

Visit our website (www.autonics.com) to download the DAQmaster program and the user manual.

Auto-tuning measures the control subject's thermal characteristics and thermal response rate, and then

determines the necessary PID time constant. Application of the PID time constant realizes fast response and

high precision temperature control. (when setting control type [

C-MD

] is set as

PID

, it is displayed.)

Set [

AT

] parameter to [

ON

] in parameter 2 group to start auto-tuning. To stop auto-tuning, change the set as [

OFF

].

(It maintains P, I, D values of before auto-tuning.)

If sensor break error [

OPEN

] occurs during auto-tuning, it stops this operation. If the measured temperature is

over or below the input range, it operates continuously.

During auto-tuning operation, whole parameters are only available to check.

Mode Name Alarm operation Description

OFF

- -

No alarm output

DVCC

Deviation

high-limit

alarm

If deviation between PV and SV

as high-limit is higher than set

value of deviation temperature,

the alarm output will be ON.

]]DV

Deviation

low-limit

alarm

If deviation between PV and SV

as low-limit is higher than set

value of deviation temperature,

the alarm output will be ON.

]DVC

Deviation

high/low-limit

alarm

If deviation between PV and

SV as high/low-limit is higher

than set value of deviation

temperature, the alarm output

will be ON.

CDV]

Deviation

high/low-limit

reserve alarm

If deviation between PV and

SV as high/low-limit is lower

than set value of deviation

temperature, the alarm output

will be OFF.

PVCC

Absolute

value high-

limit alarm

If PV is higher than the absolute

value, the output will be ON.

]]PV

Absolute

value low-limit

alarm

If PV is lower than the absoulte

value, the output will be ON.

LBA

Loop break

alarm

-

It will be ON when it detects

loop break.

SBA

Sensor break

alarm

-

It will be ON when it detects

sensor disconnection.

HBA

Heater break

alarm

-

It will be ON when CT detects

heater break.

Mode Name Description

AL-A

Standard alarm

If it is an alarm condition, alarm output is ON. If it is a clear alarm condition, alarm output is OFF.

AL-B

Alarm latch If it is an alarm condition, alarm output is ON and maintains ON status.

AL-C

Standby

sequence 1

First alarm condition is ignored and from second alarm condition, standard alarm

operates. When power is supplied and it is an alarm condition, this rst alarm

condition is ignored and from the second alarm condition, standard alarm operates.

AL-D

Alarm latch

and standby

sequence 1

If it is an alarm condition, it operates both alarm latch and standby sequence. When

power is supplied and it is an alarm condition, this rst alarm condition is ignored and

from the second 1alarm condition, alarm latch operates.

AL-E

Standby

sequence 2

First alarm condition is ignored and from second alarm condition, standard alarm

operates. When re-applied standby sequence and if it is alarm condition, alarm output

does not turn ON. After clearing alarm condition, standard alarm operates.

AL-F

Alarm latch

and standby

sequence 2

Basic operation is same as alarm latch and standby sequence1. It operates not only

by power ON/OFF, but also alarm set value, or alarm option changing. When re-

applied standby sequence and if it is alarm condition, alarm output does not turn ON.

After clearing alarm condition, alarm latch operates.

The above is masking auto tuning [

AT

], cooling proportional band [

C-P

], cooling integral time [

C-1

],

cooling derivative time [

C-D

] parameters in parameter 2 group.

The above is setting user parameter group in the DAQMaster with alarm output 1 low-limit value [

AL!L

], alarm output 1

high-limit value [

AL!H

], SV-0 set value [

SV-0

] parameter of parameter 1 group, heating hysteresis[

hHYS

],

cooling hysteresis [

cHYS

] parameters of parameter 2 group, input correction [

IN-B

] parameter of parameter 3

group, alarm output 1 hysteresis [

A!HY

], alarm output 2 hysteresis [

A@HY

] parameters of parameter 4 group.

Before applying mask

After applying mask

PASS

Run mode

PASS

Alarm output2 low-limit set value[

AL@L

]

SV-0 set value[

SV-0

]

Alarm output1 low-limit set value[

AL!L

]

Alarm output3 low-limit set value[

AL#L

]

SV-2 set value[

SV-2

]

Heater current monitoring[

CT-A

]

Alarm output2 high-limit set value[

AL@H

]

SV-1 set value[

SV-1

]

Alarm output1 high-limit set value[

AL!H

]

Alarm output3 high-limit set value[

AL#H

]

SV-3 set value[

SV-3

]

Heating proportional band[

H-P

]

Auto-tuning RUN/STOP[

AT

]

Heating derivative time[

H-D

]

Heating hysteresis[

hHYS

]

Heating integral time[

H-I

]

Dead_overlap band[

DB

]

Cooling hysteresis[

cHYS

]

MV high-limit[

H-MV

]

RAMP time unit[

rUNT

]

Cooling proportional band[

C-P

]

Cooling derivative time[

C-D

]

Heating OFF offset[

hOST

]

MV low-limit[

L-MV

]

RAMP-down change rate[

RAMD

]

Cooling integral time[

C-I

]

Manual reset[

REST

]

Cooling OFF offset[

cOST

]

RAMP-up change rate[

RAMU

]

Sensor temperature unit[

UNIT

]

Input type[

IN-T

]

Alarm output1 option[

AL!T

]

Alarm output1operation mode[

AL-1

]

Alarm output3 option[

AL#T

]

Low-limit scale value[

L-SC

] Alarm1 OFF delay time[

A!OF

]

Alarm 3 OFF delay time[

A#OF

]

Input digital lter[

MAvF

]

Auto-tuning mode[

AtT

]

Alarm 2 N.O./N.C.[

A@N

]

Trans. output 1 low-limit value[

FsL1

]

Analog high-limit input value[

H-RG

]

Alarm1 N.O./N.C.[

A!N

]

Alarm 3 N.O./N.C.[

A#N

]

Display unit[

dUNT

] Alarm output2 option[

AL@T

]

LBA band[

LBaB

]

SV high-limit[

H-SV

]

OUT1 SSR drive output type[

O!SR

]

Alarm 2 OFF delay time[

A@OF

]

Analog trans. output 2 mode[

AoM2

]

Analog low-limit input value[

L-RG

]

Alarm output1 hysteresis[

A!HY

]

Alarm output3 hysteresis[

A#HY

]

High-limit scale value[

H-SC

]

Alarm output2 operation mode[

AL-2

]

LBA time[

LBaT

]

SV low-limit[

L-SV

]

OUT1 control output selection[

OUT1

]

Alarm 2 ON delay time[

A@ON

]

Trans. output 1 high-limit value[

FsH1

]

Scaling decimal point[

DOT

] Alarm1 ON delay time[

A!ON

]

Alarm 3 ON delay time[

A#ON

]

Input correction[

IN-B

]

Control type[

C-MD

]

Alarm output2 hysteresis[

A@HY

]

Analog trans. output 1 mode[

AoM1

]

Control output operation mode[

O-FT

]

OUT1 current output range[

O!MA

]

OUT2 control output selection[

OUT2

]

OUT2 current output range[

O@MA

]

Heating control time[

H-T

]

Cooling control time[

C-T

]

Alarm output3 operation mode[

AL-3

]

Trans. output 2 low-limit value[

FsL2

]

Trans. output 2 high-limit value[

FsH2

]

Comm. address[

ADRS

]

Comm. speed[

BPS

]

Comm. parity bit[

PRTY

]

Comm. stop bit[

STP

]

Comm. response waiting time[

RSwT

]

Comm. write[

COMW

]

3 sec

3 sec

①

③

②

④

①

Whole display part

②

Model type display

③

Input type display twice

④

Run mode

3 sec

3 sec

1.5 sec

1.5 sec

Heating MV

Monitoring

Cooliing MV

Monitoring

SV

100

℃

OFF

OFF

OFFOFF

OFF

OFF OFF

OFF OFF

OFF

OFFONON

ON ON

ON

ON ON

ONON

ON ON

HH

H H

HH

H H

H H

HH

PV

90

℃

PV

90

℃

PV

90

℃

PV

90

℃

PV

90

℃

High deviation: Set as 10

℃

Low deviation: Set as 10

℃

Absolute-value: Set as 90

℃

Absolute-value: Set as 90

℃

Low deviation : Set as 10

℃

, High deviation : Set as 20

℃

Low deviation : Set as 10

℃

, High deviation : Set as 20

℃

High deviation: Set as -10

℃

Low deviation: Set as -10

℃

Absolute-value: Set as 110

℃

Absolute-value: Set as 110

℃

PV

110

℃

SV

100

℃

SV

100

℃

SV

100

℃

SV

100

℃

SV

100

℃

PV

120

℃

PV

120

℃

PV

90

℃

SV

100

℃

SV

100

℃

SV

100

℃

SV

100

℃

PV

110

℃

PV

110

℃

PV

110

℃

1.5 sec

1.5 sec

1.5 sec

2 sec

3 sec

3 sec

Digital input key[

DI-K

]

Multi SV[

MtSV

]

Manual control, preset MV[

PrMV

]

User level[

USER

]

Parameter 3group lock[

LcP3

]

DI-2 input terminal function[

DI-2

]

Control stop, MV[

StMV

]

Parameter 1group lock[

LcP1

]

Parameter 5group lock[

LcP5

]

DI-1 input terminal function[

DI-1

]

Sensor error, MV[

ErMV

]

SV setting lock[

LcSV

]

Parameter 4group lock[

LcP4

]

Manual control, initial MV[

ItMV

]

Control stop, alarm output[

StAL

]

Parameter 2group lock[

LcP2

]

Password setting[

PWD

]

PAR2 AT H-P C-P H-I C-I H-D C-D

PAR2 H-P H-I H-D

●SV setting group [

SV

]

●Parameter 1 group [

PAR1

]

●Parameter 2 group [

PAR2

]

●Parameter 3 group [

PAR3

]

●Parameter 4 group [

PAR4

]

●Parameter 5 group [

PAR5

]

●Password input parameter

Run mode

AL!L AL!H SV-0 hHYS cHYS IN-B A!HY A@HY

PARU PAR1 PAR2

Item Minimum specications

System IBM PC compatible computer with Pentium

Ⅲ

or above

Operations Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS232C serial port (9-pin), USB port

1.

Follow instructions in 'Cautions during Use'. Otherwise, It may cause unexpected accidents.

2. Check the polarity of the terminals before wiring the temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the designated compensation wire for extending wire.

3. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line filter or varistor at power line and shielded

wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

4. Do not apply excessive power when connecting or disconnecting the connectors of the product.

5. Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the

power.

6. Do not use the unit for other purpose (e.g. voltmeter, ammeter), but temperature controller.

7. When changing the input sensor, turn off the power first before changing.

After changing the input sensor, modify the value of the corresponding parameter.

8. 24VAC, 24-48VDC power supply should be insulated and limited voltage/current or Class 2, SELV power

supply device.

9. Do not overlapping communication line and power line.

Use twisted pair wire for communication line and connect ferrite bead at each end of line to reduce the effect

of external noise.

10. Make a required space around the unit for radiation of heat.

For accurate temperature measurement, warm up the unit over 20 min after turning on the power.

11. Make sure that power supply voltage reaches to the rated voltage within 2 sec after supplying power.

12. Do not wire to terminals which are not used.

13. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specifications')

②

Altitude max. 2,000m

③

Pollution degree 2

④

Installation category II

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO

₂

, Nd: YAG)

Laser Welding/Cutting System

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513beon-gil, Haeundae-gu, Busan,

South Korea, 48002

TEL: 82-51-519-3232

E-mail:

sales@autonics.com

DRW170598A A

Input type Decimal point Display Input range (

℃

) Input range (

℉

)

Thermocouple

K (CA)

1

KCaH

-200 to 1350 -328 to 2463

0.1

KCaL

-199.9 to 999.9 -199.9 to 999.9

J (IC)

1

JIcH

-200 to 800 -328 to 1472

0.1

JIcL

-199.9 to 800.0 -199.9 to 999.9

E (CR)

1

ECrH

-200 to 800 -328 to 1472

0.1

ECrL

-199.9 to 800.0 -199.9 to 999.9

T (CC)

1

TCcH

-200 to 400 -328 to 752

0.1

TCcL

-199.9 to 400.0 -199.9 to 752.0

B (PR) 1

B PR

0 to 1800 32 to 3272

R (PR) 1

R PR

0 to 1750 32 to 3182

S (PR) 1

S PR

0 to 1750 32 to 3182

N (NN) 1

N NN

-200 to 1300 -328 to 2372

C (TT)

※

1

1

C TT

0 to 2300 32 to 4172

G (TT)

※

2

1

G TT

0 to 2300 32 to 4172

L (IC)

1

LIcH

-200 to 900 -328 to 1652

0.1

LIcL

-199.9 to 900.0 -199.9 to 999.9

U (CC)

1

UCcH

-200 to 400 -328 to 752

0.1

UCcL

-199.9 to 400.0 -199.9 to 752.0

Platinel II 1

PLII

0 to 1390 32 to 2534

RTD

Cu 50Ω 0.1

CU 5

-199.9 to 200.0 -199.9 to 392.0

Cu 100Ω 0.1

CU10

-199.9 to 200.0 -199.9 to 392.0

JPt 100Ω

1

JPtH

-200 to 650 -328 to 1202

0.1

JPtL

-199.9 to 650.0 -199.9 to 999.9

DPt 50Ω 0.1

DPt5

-199.9 to 600.0 -199.9 to 999.9

DPt 100Ω

1

DPtH

-200 to 650 -328 to 1202

0.1

DPtL

-199.9 to 650.0 -199.9 to 999.9

Nickel 120Ω 1

NI12

-80 to 200 -112 to 392

Analog

Voltage

0-10V

AV1

-1999 to 9999

(Display point will be changed

according to decimal point position.)

0-5V

AV2

1-5V

AV3

0-100mV

AMV1

Current

0-20mA

AMA1

4-20mA

AMA2

Parameter Reset

Press

+ +

to reset all parameters in memory to default value.

Set [

INIT

] parameter to '

YES

' to reset all parameters.

In case password function is on, it is required to enter valid password to reset parameters.

Password is also reset.

Loading...

Loading...