Autostacker™ Parking Lift 37 P/N 5900248 — Rev. B — May 2021

Lubricate the Lift

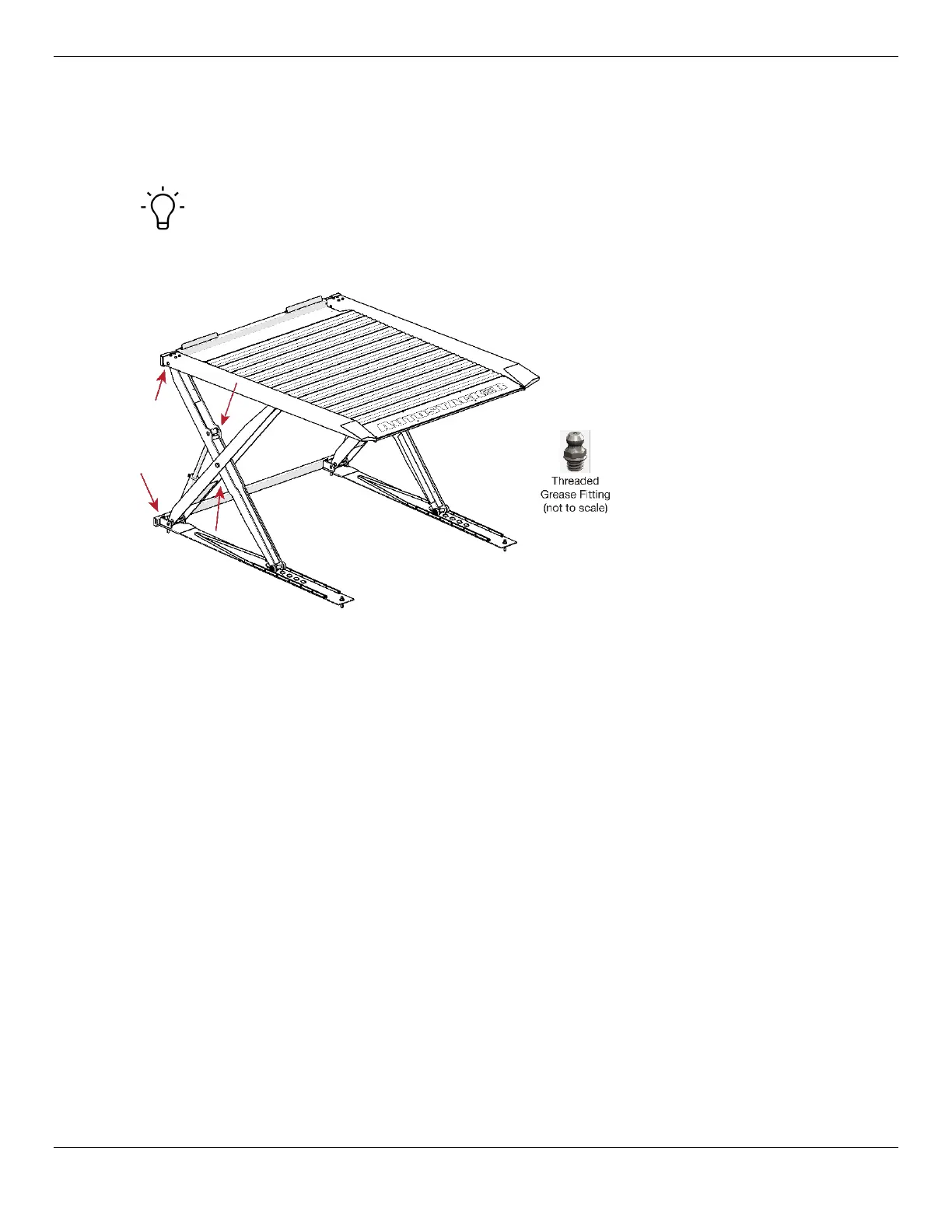

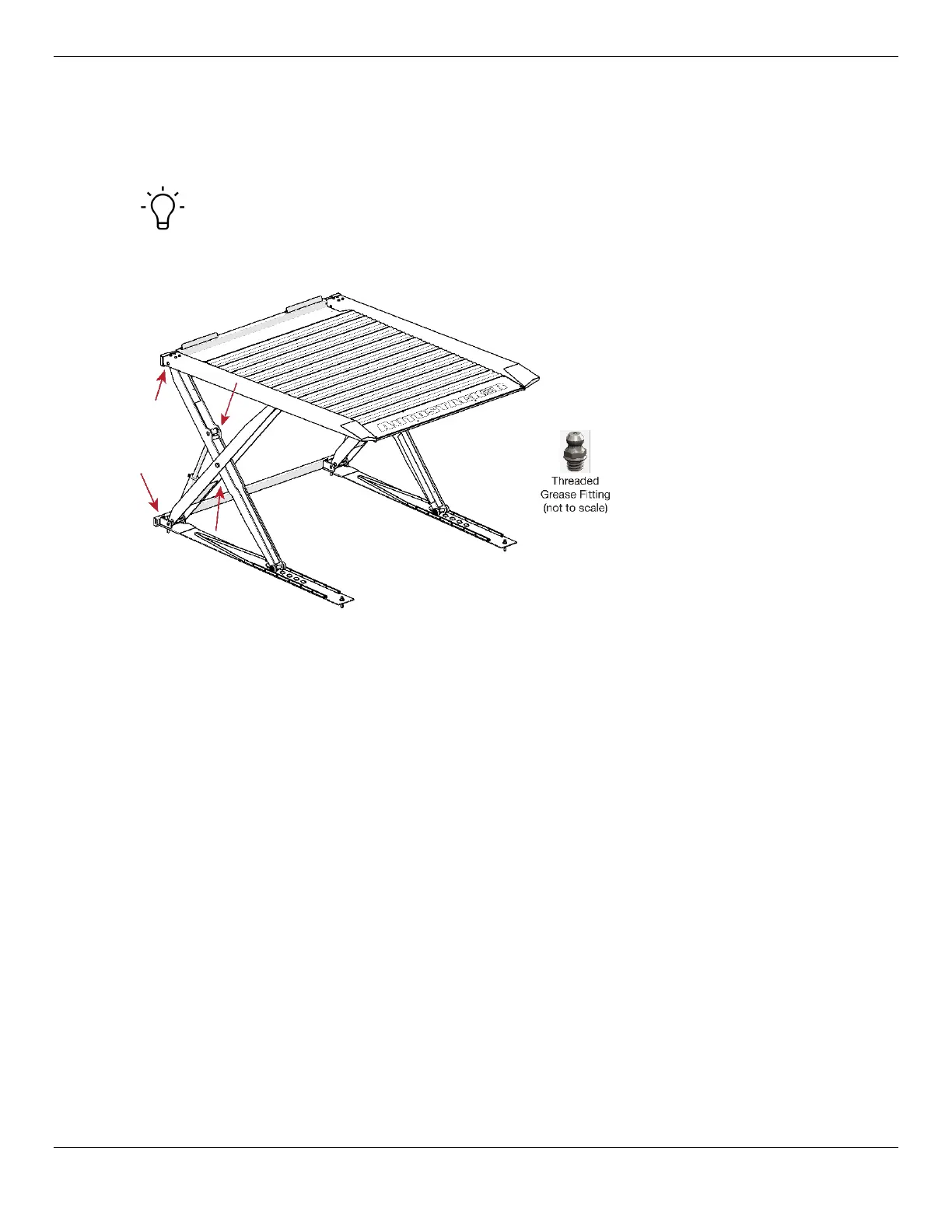

The Autostacker has eight Lubrication Points, four on each Leg Assembly. You must grease the

Threaded Grease Fitting (P/N 5550025) at the Lubrication Points before you start normal operation of

your Autostacker. Refer to Maintenance for more information.

Tip Autostacker recommends using white lithium grease, or similar, and a grease gun

with an appropriate tip (a Lube-Link™, for example) when lubricating your lift.

The Threaded Grease Fittings / Lubrication Points on each Leg Assembly are:

Final Checklist

Make sure these things have been done before using your Lift:

• Review the Installation Checklist to make sure all steps have been performed.

• Make sure the Power Unit is getting power from the power source.

• Check the Power Unit’s Hydraulic Fluid reservoir; it must be full of approved Hydraulic Fluid or

automatic transmission fluid. You can harm the motor by running it without enough fluid.

• Check the Hydraulic System for leaks.

• Check to see that all Anchor Bolts are properly tightened.

• Make sure that all Safety Locks are cleared and free.

• Make sure a copy of the Installation and Operation Manual is left with the equipment, so that it is

available to all operators, and make sure all labels are visible.

• Raise the Autostacker to each of the six Safety Locks and measure the space between the ground

and the bottom of the Drive-Up Ramp. Check these values against the values shown in Raising a

Vehicle. These are the actual values that you should use to determine what Vehicles you want to

put where.

• Perform an operational test of the Lift with a typical Vehicle.

During the operational test, observe all operating components and check for proper installation and

operation. Do not raise any additional vehicles until a thorough operational check has been

performed with a typical Vehicle.

If the Autostacker fails the operational test, take it out of service, then consult Troubleshooting

to begin addressing the problem.

Loading...

Loading...