Caution:

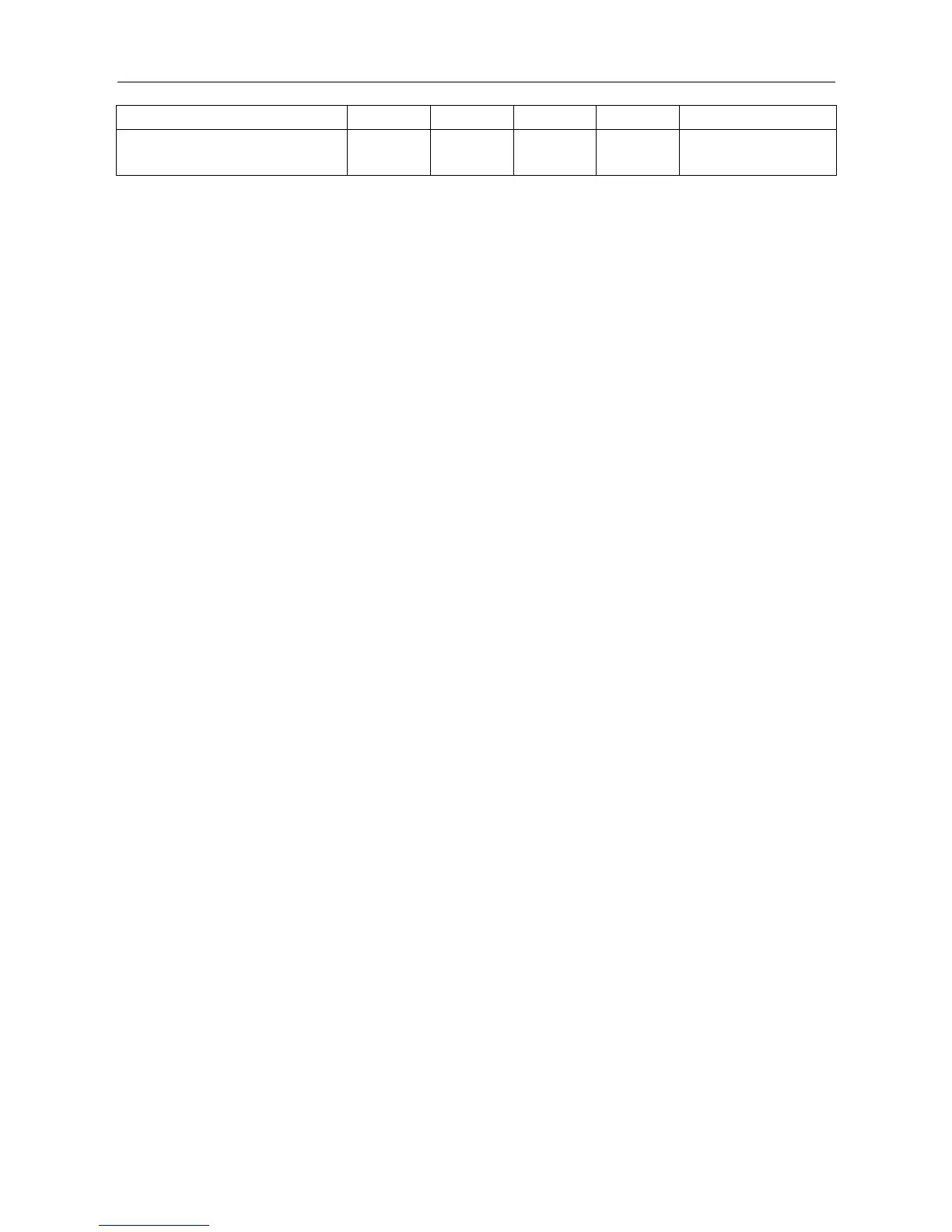

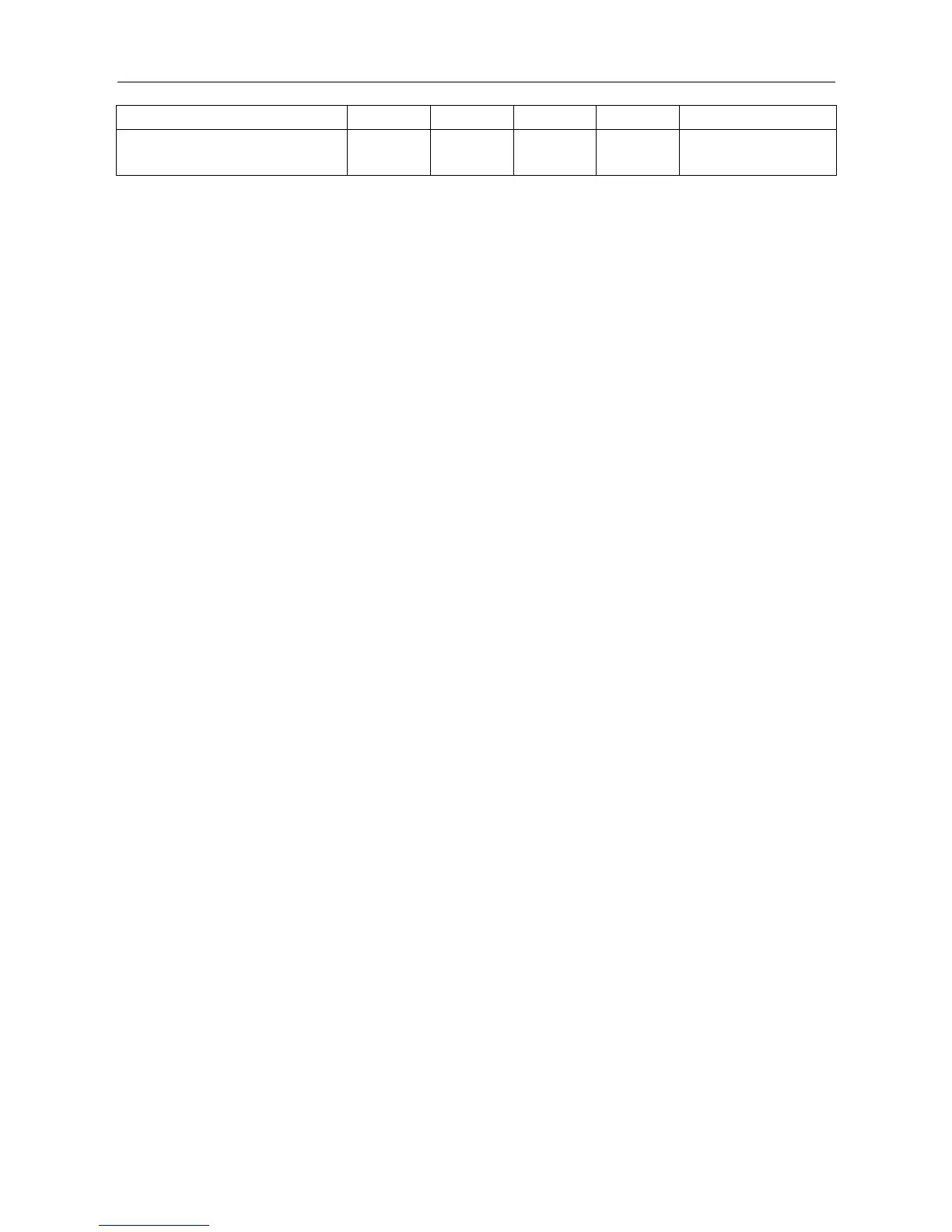

1.The standard Pipe length is 5m, if the pipe length is less than this then no additional charging is

necessary. If the pipe length is more than this then you should charge more refrigerant into the system

according to the above Charging Data

2.The thickness of the pipe is 0.5-1.0, bearing pressure is 3.040MPa;

3.If the connection pipe is too long, the cooling capacity and stability would be decreased. And the more

bend quantity, the resistance in the piping system would be bigger, then the cooling and heating capacity

would be decreased even lead to compressor broken. We suggest you to use the shortest connection

pipe according to the pipe length parameter in this manual.

Emptying or vacuum

Before charging the refrigerant to the system, to ensure that there is no impurities, water or

non-condensable gas. So, emptying and vacuum operation should be carried out.

◇Vacuum: when process this operation please be sure that the connection pipe is tightened up.

1. Screw off the cover of maintenance valve connection, connect the pressure gauge to the connection of

maintenance valve

2. Connect the vacuum pump to the pressure gauge, turn on the vacuum pump and pressure gauge to

process the vacuum operation toward the indoor unit and piping, while to ensure that the absolute

pressure is no less than 50Pa after this operation.

3. Turn off the pressure gauge and vacuum pump to keep the pressure in the same level in 20 minutes.

◇Emptying: when process this operation, please disconnect the high pressure valve with liquid valve.

1. Connect the gas valve of the stop valve to the thimble side of the rubber hoses, the other side of rubber

hoses should be connected to the refrigerant tank.

2. Open the refrigerant tank valve, using the refrigerant inside the tank with high speed to empty the air in

the indoor unit and the connection piping. When the outlet air becomes mist (it feels cold by touching it),

then the air is emptied.

3. When ensure that the air is emptied, connect and tighten the high pressure valve of outdoor unit stop

valve and liquid side connection pipe, keep this state more than 10 seconds.

4. Use soapy what to test each connection junctions (including lengthen piping welding junction)

5. Confirmed that there is no leakage, turn off the valve of refrigerant tank, take down the rubber hose as

well.

◇Turn on the high-low pressure valve of the outdoor unit.

After vacuum and emptying, screw back the cover of the maintenance valve of outdoor unit low pressure

valve, screw off the high-low pressure valve of the outdoor unit (note: shall totally turned off ). Connect the

refrigerant to the system.

Loading...

Loading...