Avant 220/225

65

The hydraulic pressure filter:

Located at the right side of the loader, beside the

hydraulic pumps. Use general filter replacement

tool to unscrew the filter.

9. Check pressure of hydraulic system

Pressure checking points and pressure settings for

different functions are listed below.

It is recommended to leave the checking operation to

qualified service technicians. At minimum, a

hydraulic pressure gauge with appropriate

measurement scale and a measurement fitting is

required.

Risk of injection of hydraulic oil

- Wrong handling of the

hydraulic system or wrong tools

can cause ejection of hydraulic

oil. It is recommended that

pressures should only be checked

or adjusted by a competent and

experienced technician. Contact

your AVANT dealer if you need

assistance.

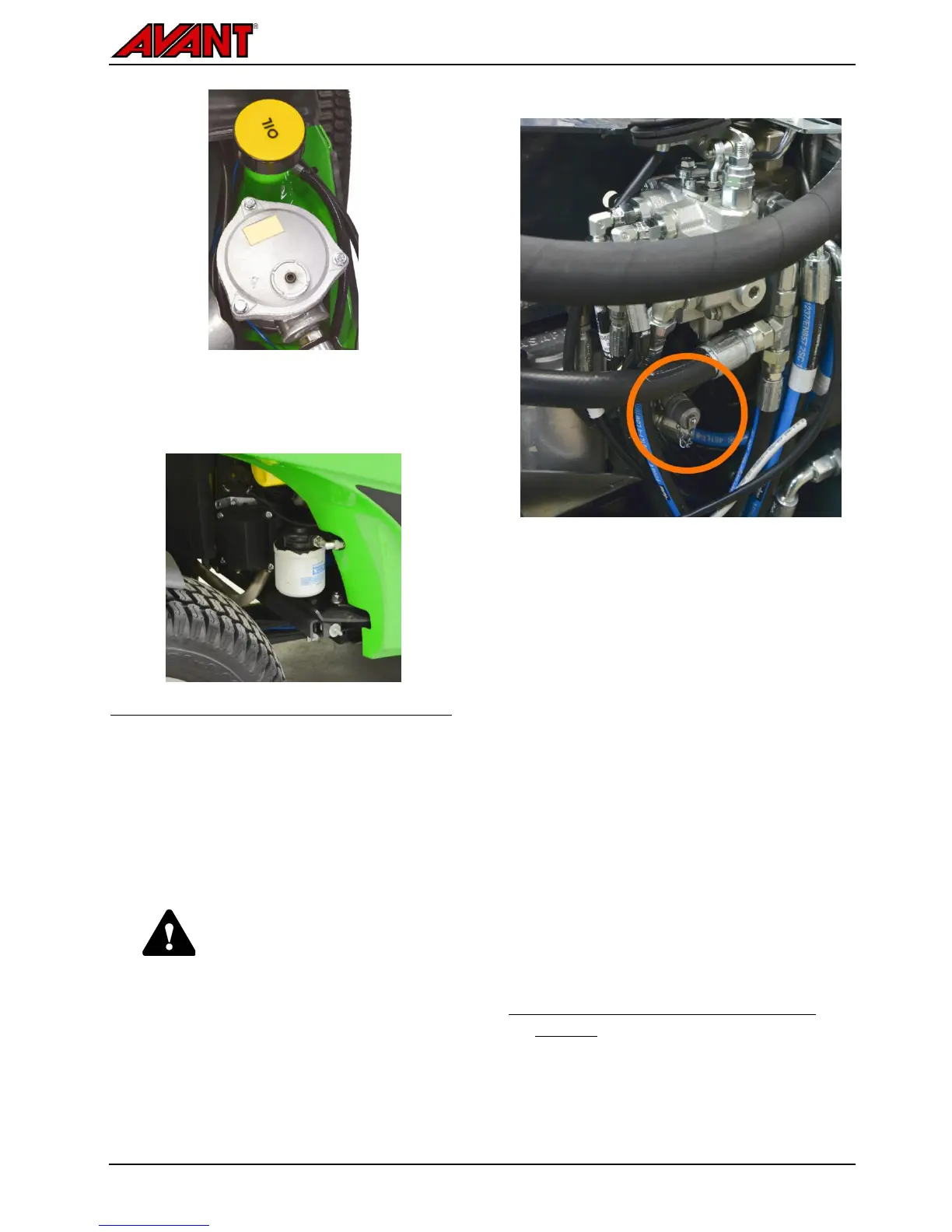

Boom lifting pressure:

Pressure is checked from the manometer fitting

mounted on the main control valve, and shown in the

picture above.

Pressure is measured with full engine revs and by

turning e.g. the bucket tilt control to end position.

Pressure setting should be 20,0 MPa (200 bar).

Auxiliary hydraulics pressure:

Pressure is checked from the auxiliary hydraulics

outlet with full revs and by turning the aux. hydraulics

control lever.

Pressure setting should be 20,0 MPa (200 bar).

Drive pressure:

In order to check the pressure in the drive circuit one

needs to mount a pressure gauge in the pressure

line in each and every case, if pressure seems to be

clearly wrong. There are two pressure relief

cartridges which have fixed 28,0 MPa (280 bar)

pressure setting.

10. Adjust pressure of hydraulic

system

If the pressure of hydraulic system does not seem to

be correct or pressure check indicates that the

pressure is wrong, it can be adjusted.

Loading...

Loading...