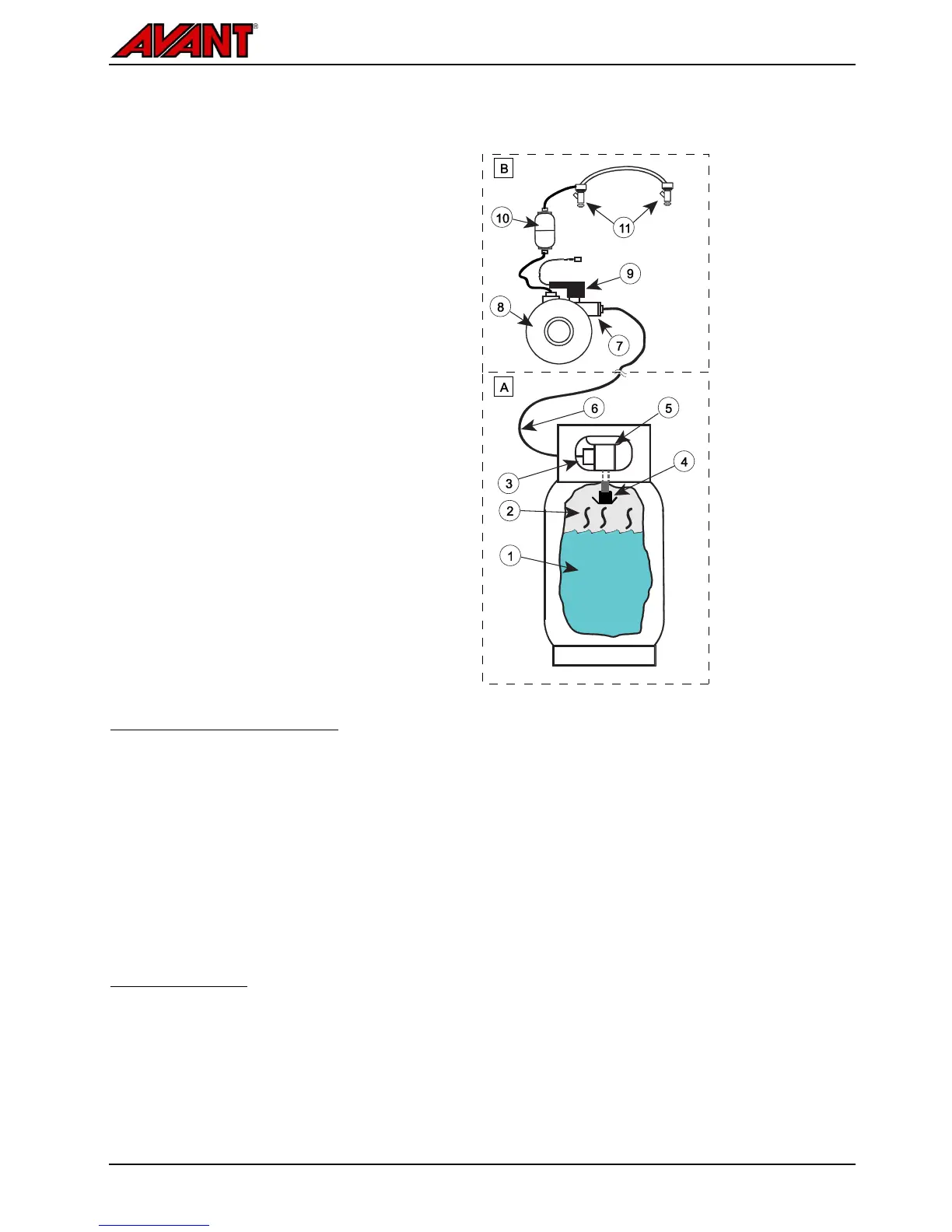

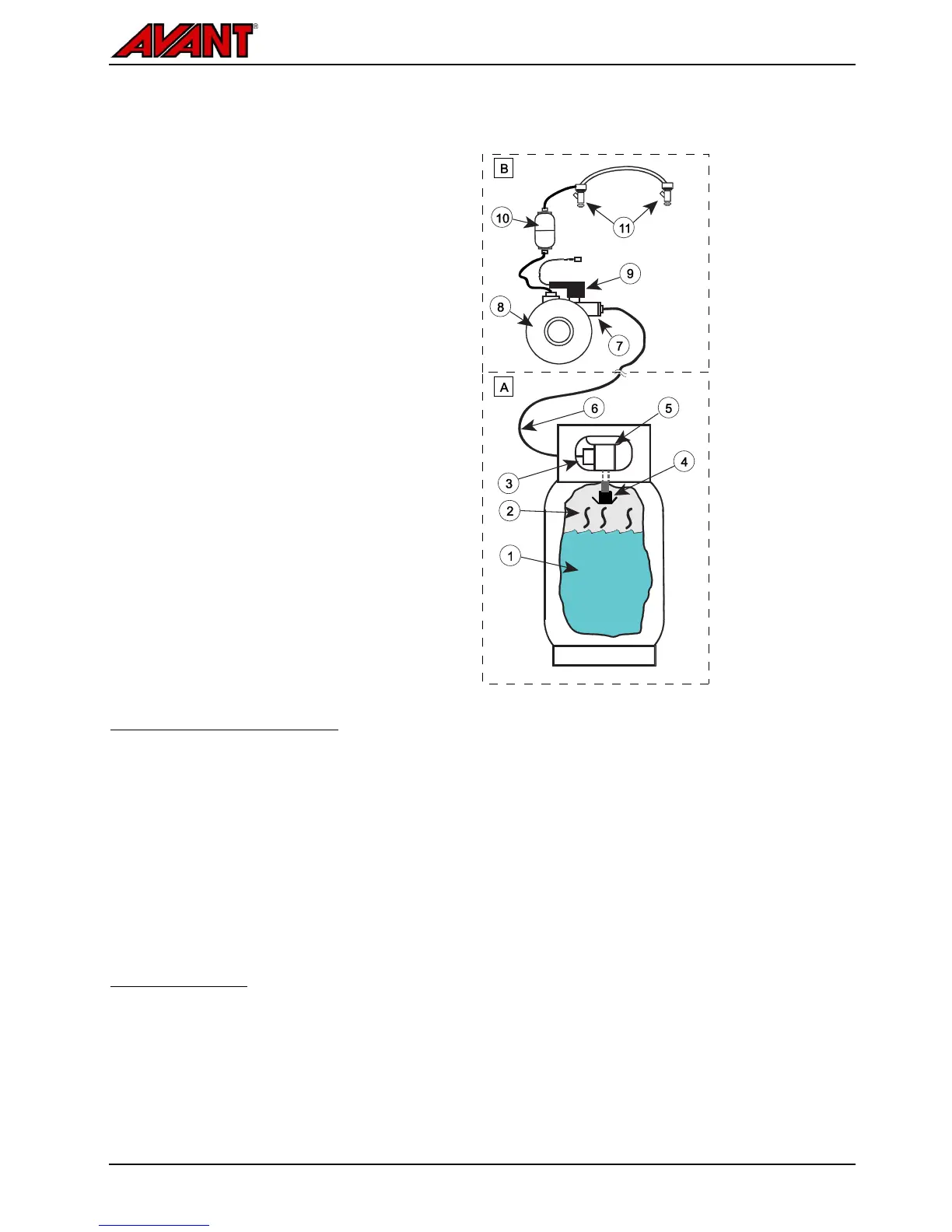

LPG system maintenance

Over time, depending on fuel quality, operating

environment, and system performance, fuel deposits

can accumulate inside pressure regulator. See the

operator's manual of the engine for instructions to

remove any accumulated deposits.

The regulator is pre-adjusted at factory and must not

be opened or adjusted to comply with emissions and

safety standards. All other service than described

above related to regulator or the EFI system must be

performed by authorised service only.

Check for leaks

If a gaseous odour is detected, close LPG bottle

valve, turn off loader main switch, and ventilate area.

Find out cause for gas odour before attempting to

restart. To ensure personal safety, installation and

repair of propane fuel supply systems must be

performed only by qualified service technicians,

contact Avant service.

LPG is usually perfumed, in order that gas smell can

be recognised. Because of the perfume the gas

smells somewhat also in normal use especially when

running a cold loader engine, and when the engine is

under high load. If the gas smell is strong, do not

start the engine. Find out the reason for the gas leak.

Use soap water to check all connectors and hoses to

check for leaks. Sophisticated leak indication solution

or gas detecting equipment can also be used. Apply

plenty of soapy water or other solution on all fittings

after tightening. After you open the gas bottle valve,

check if leaking gas causes bubbles to appear. Move

the gas hose around a little to make sure that all

fittings are tight. Close the gas bottle and wipe the

fittings clean after test.

Loading...

Loading...