8

Chapter 2. MOUNTING

Handling Precautions

•

Mount this device so that it monitors the burner at an angle from

above. If it monitors the burner at an angle from below or from

the same level, dust, soot, etc., will accumulate on the monitoring

window or in the monitoring pipe. This may block the ultraviolet

rays, preventing flame detection.

•

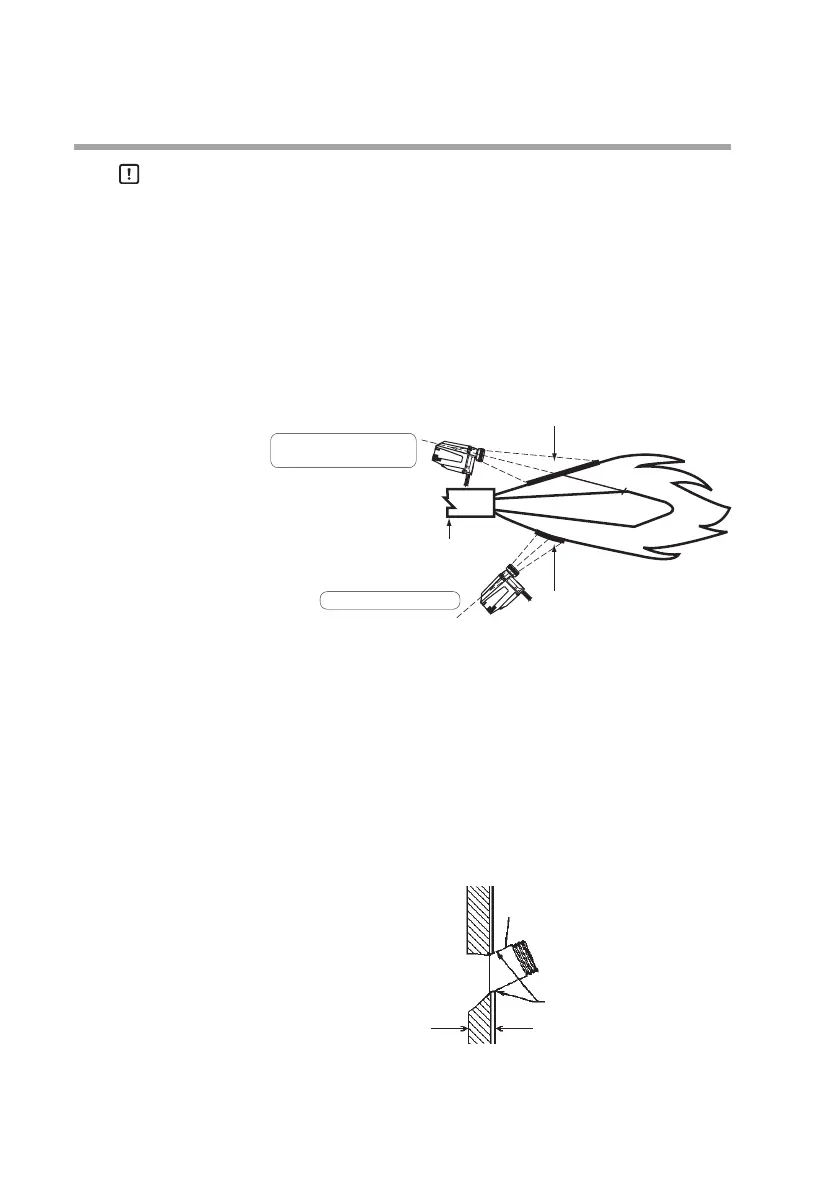

Mount this device so that its monitoring orientation intersects

the flame axis at as small an angle as possible. This maximizes the

overlap between the flame and the area monitored by the device.

Thus, the amount of detected ultraviolet rays also increases.

Flame surface area monitored is small.

Unburnt fuel

Flame surface area monitored is large and much ultraviolet radiation is detected.

Burner

Good sighting position

(low angle sighting)

Poor sighting position

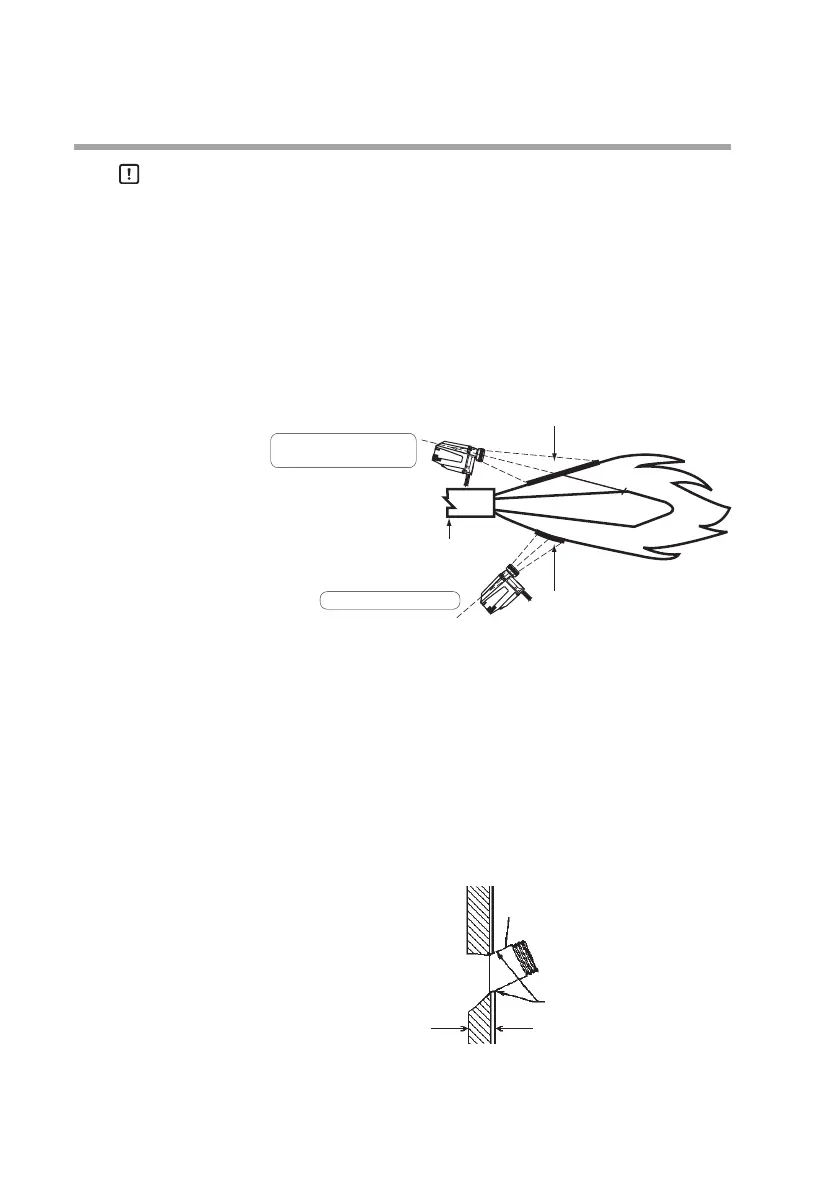

zTemporary welding for monitoring pipe positioning

(1) Preparing a monitoring pipe and making the mounting hole

Make the mounting hole at the selected location for the monitor-

ing pipe. Cut threads on one end of the monitoring pipe and cut

it to the desired length, making it as short as possible.

(2) Welding the monitoring pipe temporarily

Weld the monitoring pipe temporarily to the plate of the com-

bustion chamber of the boiler, etc. Do not weld the monitoring

pipe completely at this time, because inspection and adjustment

are required for successful flame detection.

Monitoring pipe

Temporary welds

Furnace wall (refractories) Plate

Loading...

Loading...