7

Chapter 2. MOUNTING

Handling Precautions

•

Mount this device so that it monitors the burner at an angle from

above. If it monitors the burner at an angle from below or from

the same level, dust, soot, etc., will accumulate on the monitoring

window or in the monitoring pipe. This may block the ultraviolet

rays, preventing flame detection.

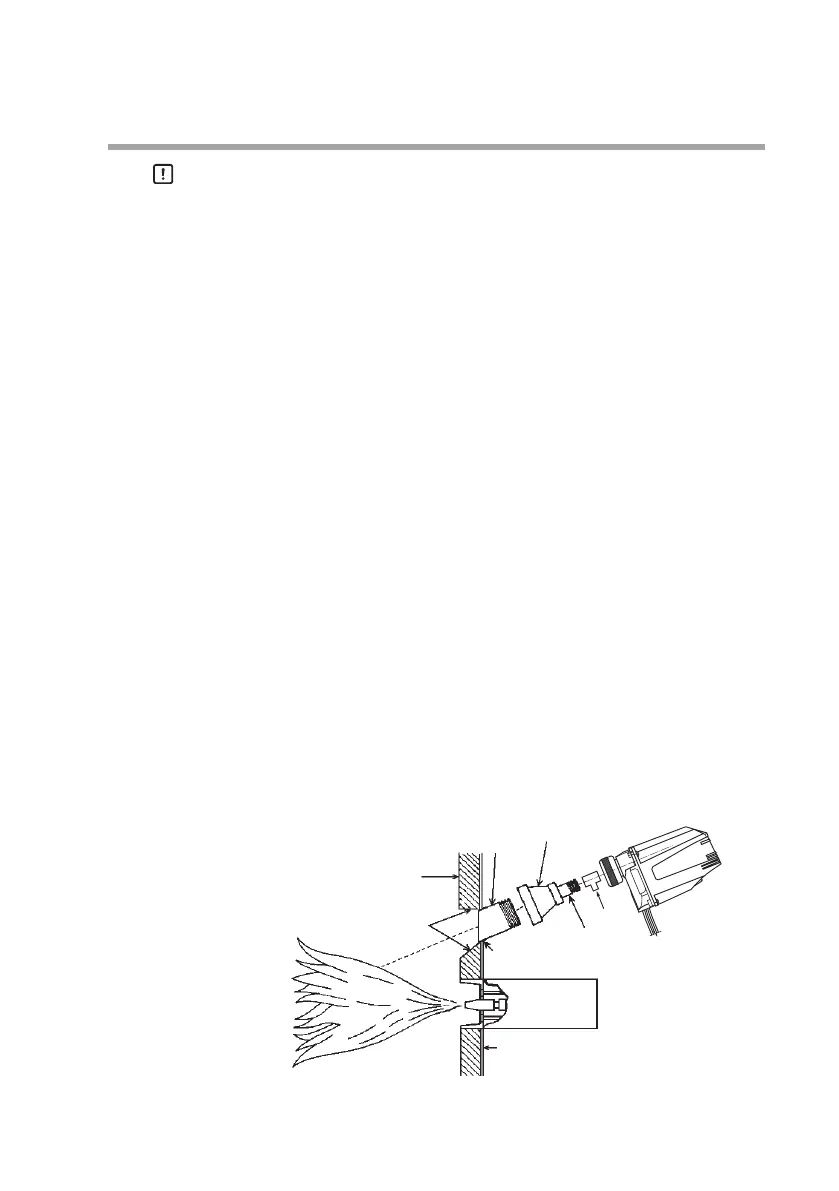

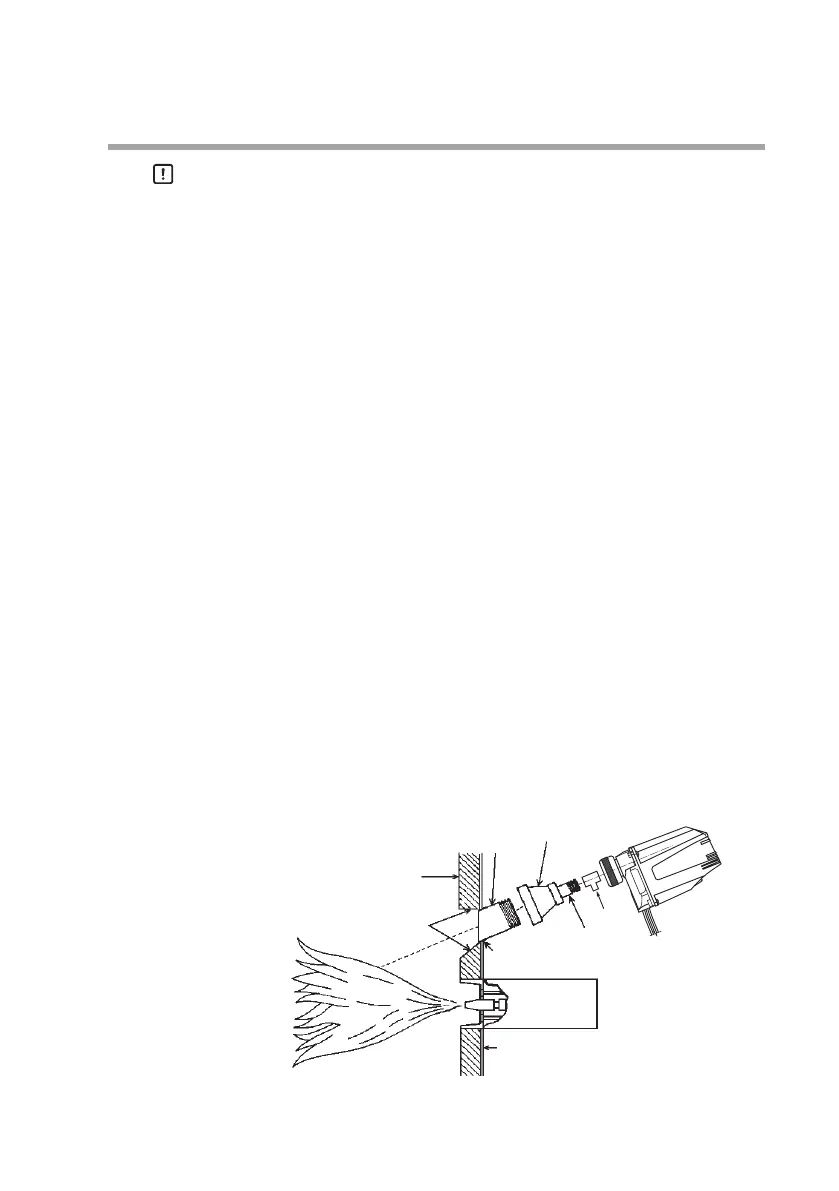

Mounting of the monitoring pipe

zMonitoring pipe materials

Use a mounting pipe with a black inside wall. If the inside wall of the

pipe has a stainless steel or electroplated surface, ultraviolet rays will

be reflected irregularly inside the pipe, causing a malfunction.

zMonitoring pipe size

To detect a large amount of ultraviolet radiation from the flame, this

device’s light-receiving surface must have a wide field of view. If the

recommended flame voltage of 2.0VDC or more cannot be ensured,

change the monitoring pipe to a wider one so that sufficient ultravio-

let radiation is received.

• Use as large a monitoring pipe as possible. Connect the pipe to the

device using a reducer.

• Make the length of the monitoring pipe as short as possible.

However, always keep the operating ambient temperature within

100°C (up to 120°C during flame detection).

zMounting space

Leave a sufficient space for easy maintenance, inspection, and service

work.

Reducing socket

Connection

nipple (1")

Weld this

part

Burner

Plate

Tapered monitoring hole

Furnace wall

Air

*

Tees

Monitoring pipe, 1" or more (Use 2" to 3" pipe.)

* If the air purging is needed, tees are

used to supply the air.

Loading...

Loading...