5. Installation and Handling

5-1. Installations

After checking following points for the installation of

Micron-Lub lubrication unit, mount the unit firmly

with 2 mounting holes so that oil tank may become

perpendicular.

* Easy maintenance.

* Easy checking for operation condition.

* Piping length for Manifold (outlet side) becomes

short

* No liquids splash, such as coolant liquid.

* Place stabilized in temperature

* Place of little vibration

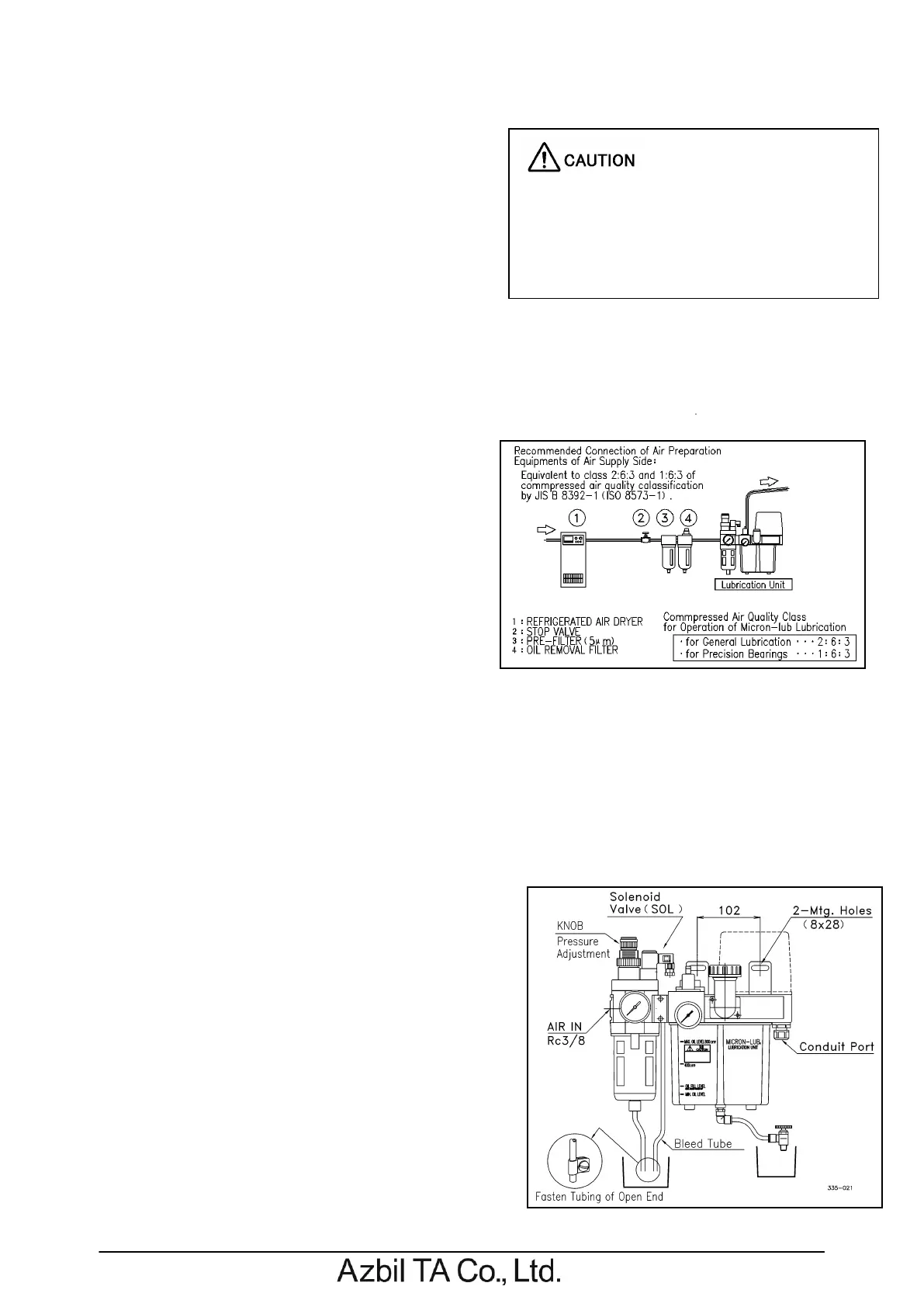

5-2. Connection of Air Preparation Equipments for Supply Air

・ Pressure air supplied to the air supply port is

required to be clean and dry.

・ Supply air should have air quality class of 2:6:3

or 1:6:3 of JIS B 8392-1 (ISO 8573-1);

compressed air quality classification.

・ Adjust supply air pressure with a regulator, or a

filter-regulator.

・ Install a stop valve and a pre-filter in upstream

side. It is useful to maintenance of equipment,

and to extension of service life of the fine

element for the oil removal filter.

・ Install a stop valve and a pre-filter in upstream side even though the model with filter-regulator

with solenoid valve is used.

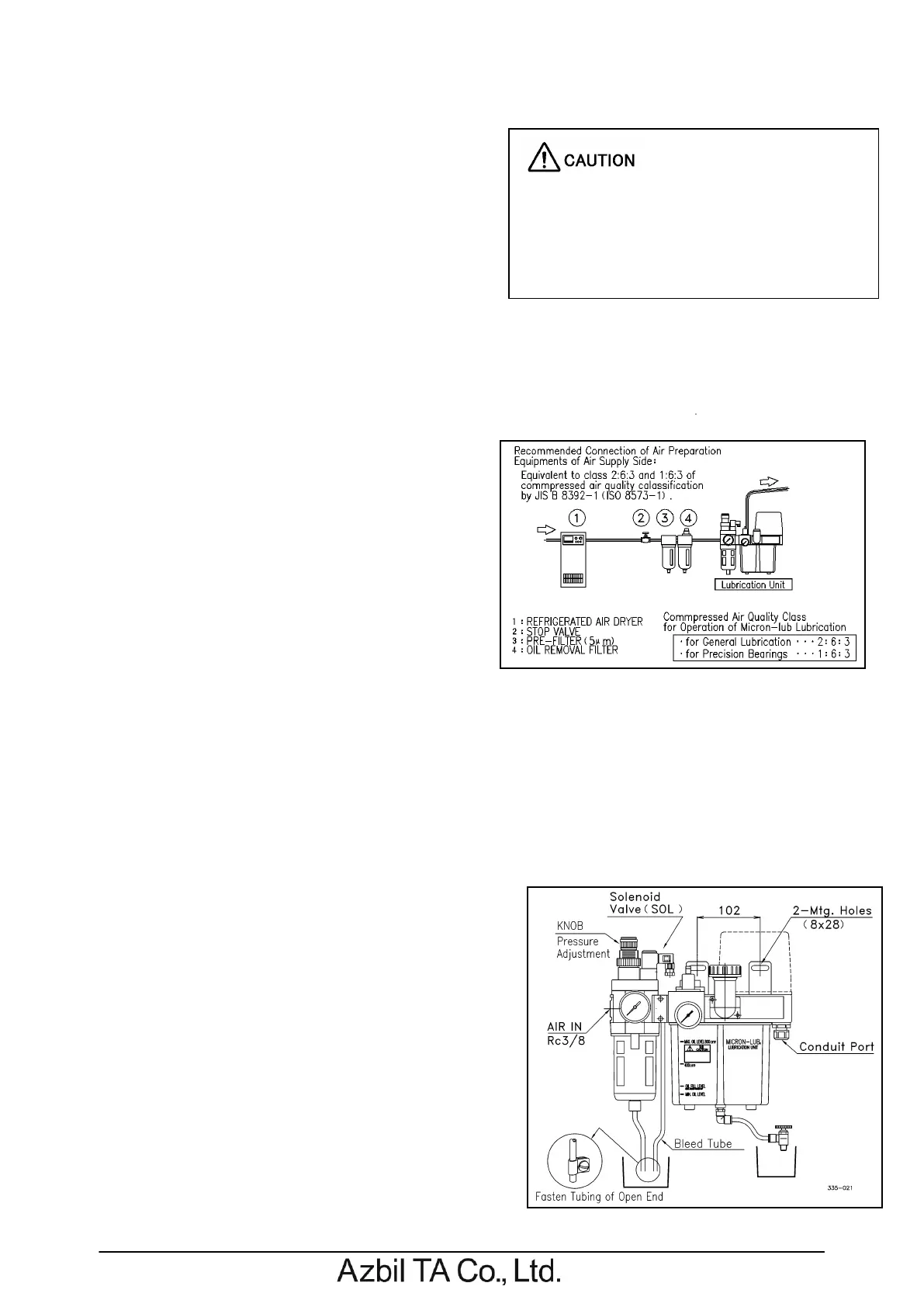

5-3. Drain Line

・Connect 6mm / OD flexible tubing to the fitting of bleeding on lift side of lubrication unit and lead

to drain pit.

・When the automatic drain type filter is being used for air supply side, connect a flexible tubing to

the drain port at bottom of the filter unit. Use tubing having an open end and within 1.8m of the

length. In addition, fix end of tubing firmly to avoid whip action.

5-4. Oil Drain Valve

・ Attach oil drain valves (stop valve, ball valve etc.) to

the oil drain port (Rc1/8) at the bottom of oil tank

through a plastic tubing.

・ Pipe plug is attached in the drain port at the time of

shipment. Remove the plug before connection of oil

drain tubing.

・ At installing a tube fitting into oil drain port of the

tank, do not screw in strongly.

・ A push-in type fitting is recommended, in order to

release the stress to oil tank.

・ Do not use together with organic solvents, such

as alcohol, thinner, and trichlene, or in the

atmosphere of these solvents exist.

・ Provide guard to protect the lubrication units

from shock. Do not throw or drop the

lubrication units.

・ Do not tread on the lubrication units.

Loading...

Loading...