5-5. Manifold Piping

Manifold piping should be worked with being careful on

the following matter.

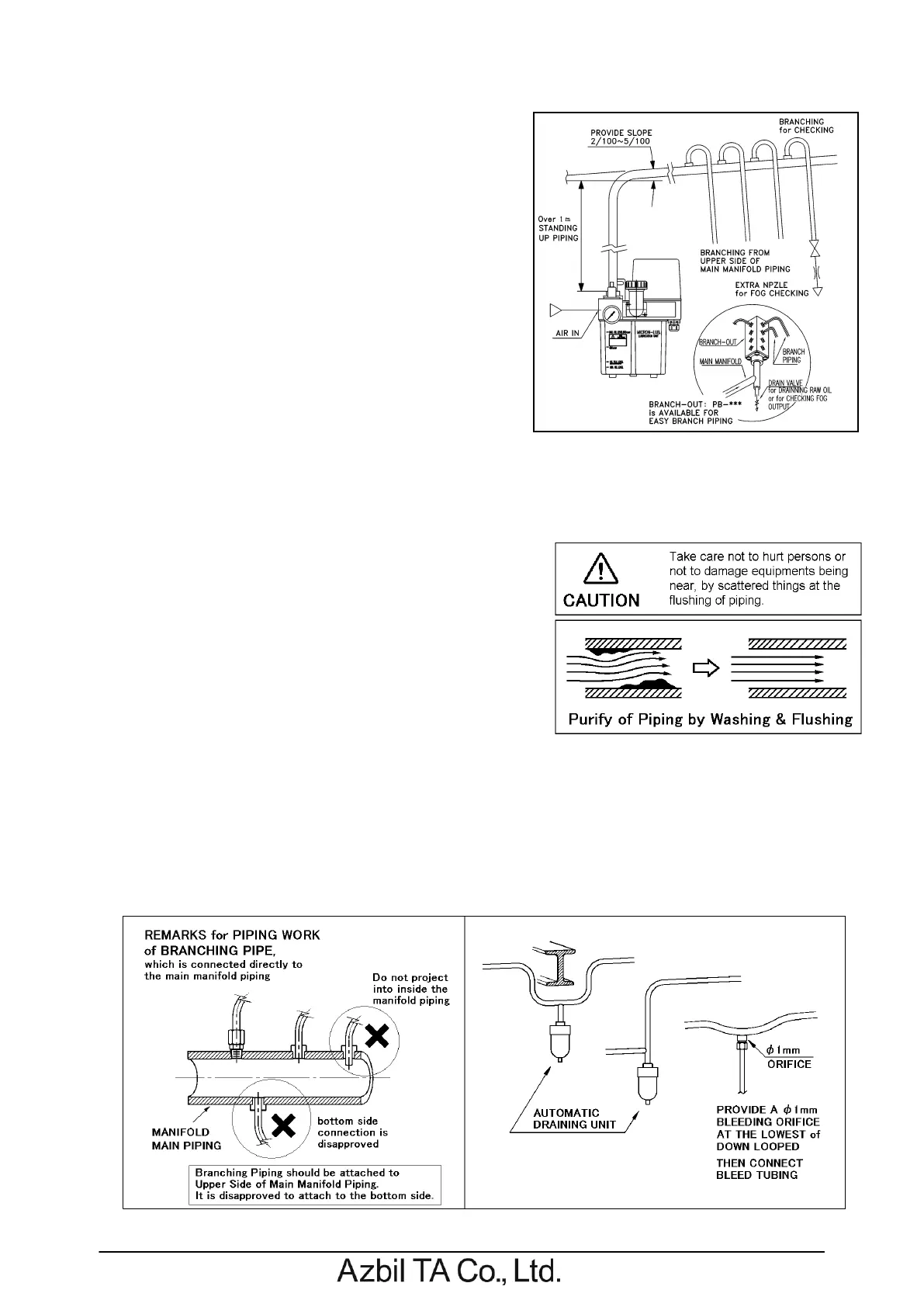

(1) Manifold piping (1/2) is required that piping of

transverse direction is performed after starting

stand-up piping (1-2m) from lubrication unit. Piping

of transverse direction should give a slope of 2/100

~5/100.

・Before starting piping work, confirm the position of

branch-out, Fog-Nozzles and etc.

・When connecting piping to the lubrication unit, take

care not to jam the seal materials and dust into

the piping.

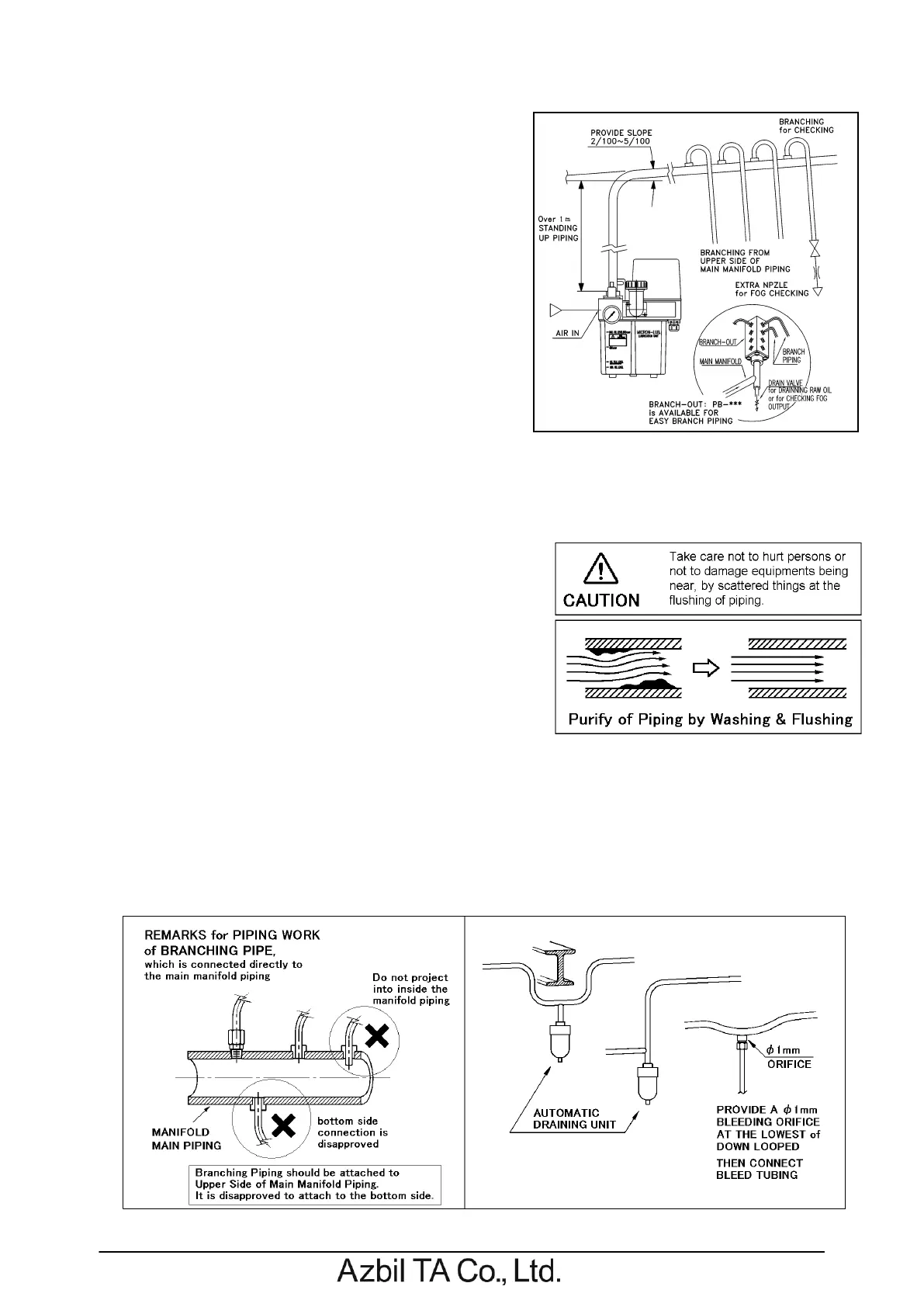

(2) Before starting piping work, piping should be

washed in pipe cleaning water and blow air to

remove dirt and scale. Flushing by compressed air

after piping work is also necessary.

(3) Piping should have the smooth inside and should

lessen use of pipe bends or pipe fittings as much as possible.

(If the flow of air becomes turbulent flow in piping, oil quantity condensed inside piping will

increase).

(4) The main manifold piping from the Micron-Lub lubrication unit to the machine to be lubricated is

preferably made of non-corrosive 1/2 pipe for gases. A

slope of 2/100~5/100 on the main manifold should be

provided descending toward the lubrication unit, and

avoid having a down loop in the course of the manifold

piping.

(5) Branch piping that distributes fog to each lubricating

point should be obtained from upper side of the main

manifold piping. Joints for branch piping should not

project inside of the main manifold piping.

(6) Install oil drainage equipment at the lowest place of

down looped piping and at bottom of standing-up

piping. Accumulated drain would be easily expelled.

(7) Check points for Fog-Nozzles.

・Type and lubricating capacity (Nozzle size).

・Installed position and the number of Fog-Nozzles.

・A distance from the tip of Fog-Nozzle to the parts to be lubricated.

・Provision of a vent port with sufficient vent, and protective method to oil contamination of

surroundings.

Loading...

Loading...