Bacharach | THE MEASURABLE DIFFERENCE | New Kensington, PA, USA | Dublin, Ireland | Toronto, Canada | mybacharach.com

HGM-MZ Sample pump flow testing

This procedure describes the correct method for testing the sampling pump in order to

determine its proper sample flow and vacuum.

HGM-MZ Pump Testing;

If the HGM- MZ is unable to pull a vacuum it will generally be due to one of two things, either the

pump is not running or failed, or there is a leak in a valve or valve stuck open in the manifold.

Flow detection is based on a minimum drop from ambient pressure and a minimum value above

vacuum, so a vacuum failure will generally result in a NO flow indication on all zones.

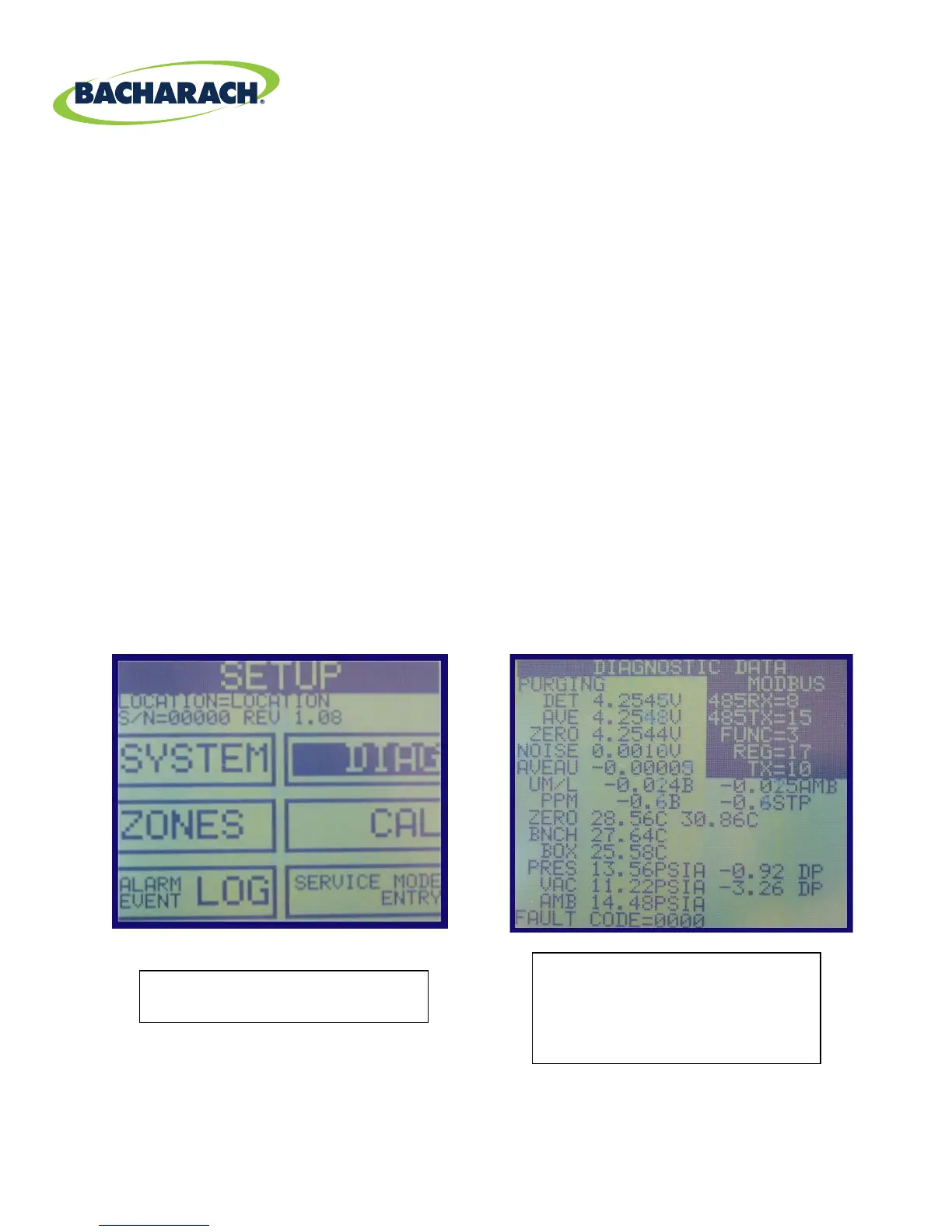

The pinch test can isolate the problem quickly. In the diagnostic screen observe the live

pressure "PRES", then pinch the tube on one side of the white disc (Hydrophobic filter) pinching

either side is OK. This will dead head the pump, a good pump will drop the pressure to

approximately 3 psia below the Ambient reading. If you get no change, the pump is not

working, the “EXHAUST” port is restricted, or there is a leak between the pinch point and the

pump.

If the pinch yields a good vacuum number, the problem is before the pinch in the valve

manifolds. One or more manifold valves are either stuck open or a failed valve driver board is

electrically holding it open. (See separate tech Bulletin on Manifold testing procedure)

Pump Vacuum (VAC)

Ambient Air Pressure (AMB)

Indicates good or bad pump

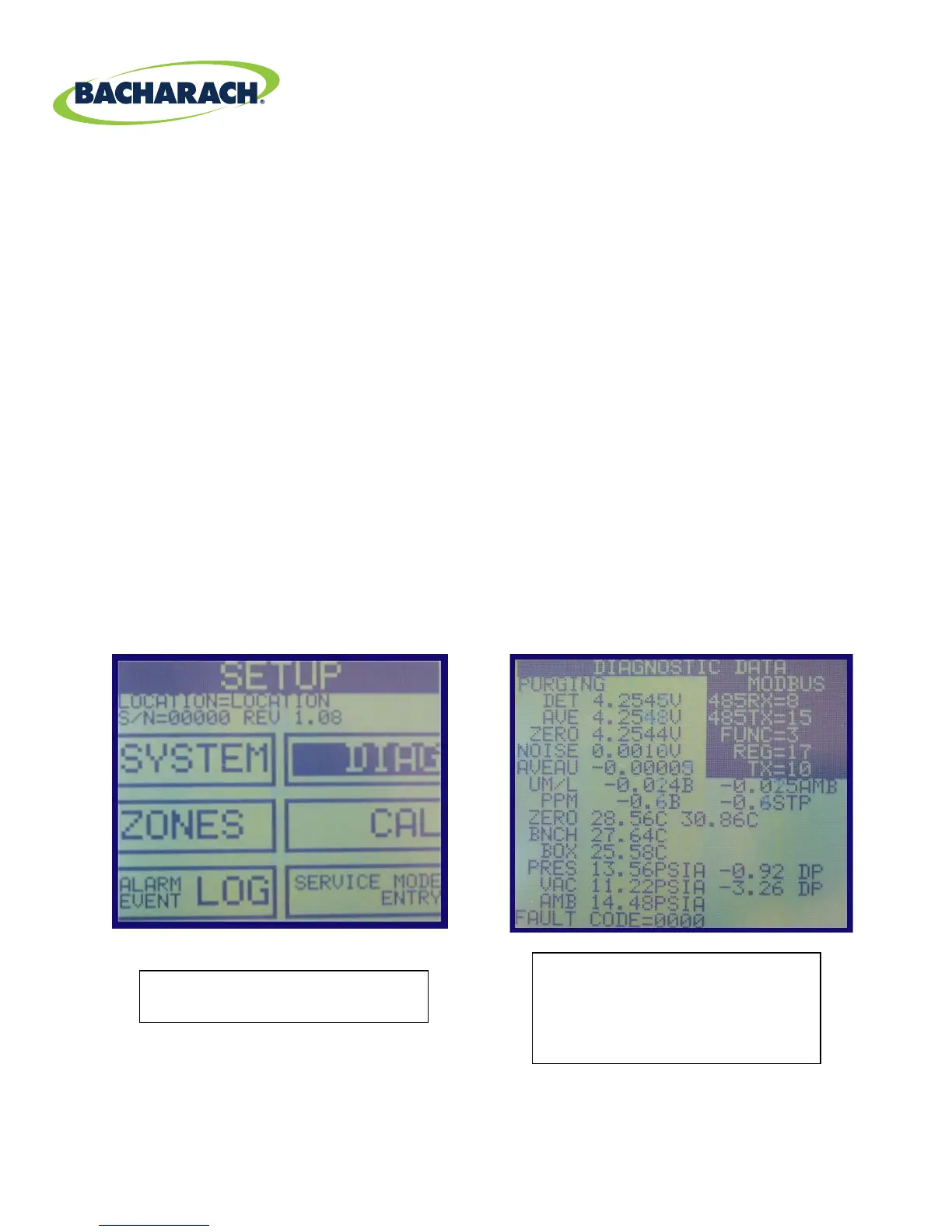

Enter Diagnostic Screen (DIAG)

From SETUP Screen

Loading...

Loading...