September 2012 Page 19

PFM Portable Hydraulic Testers PFM6, PFM6BD, and PFM8

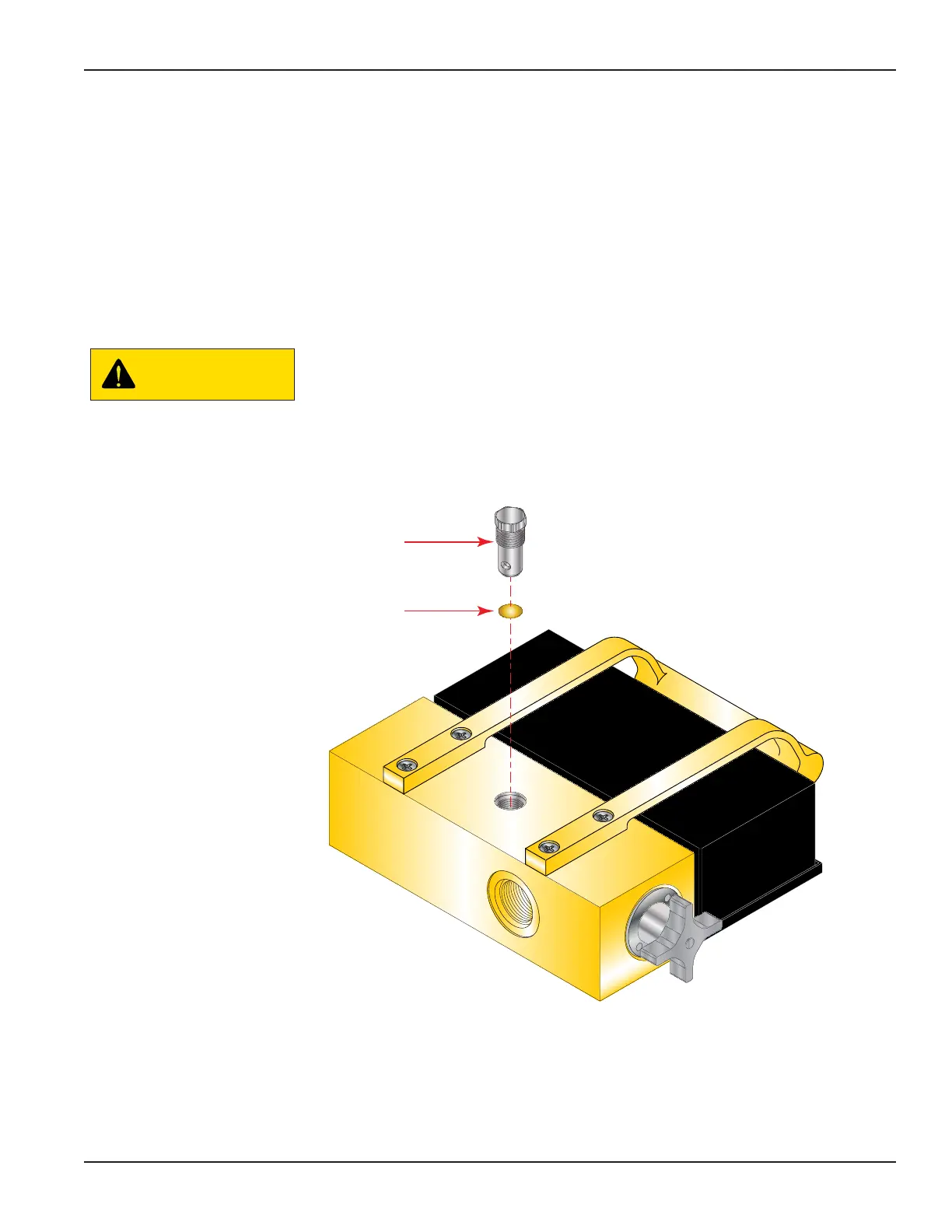

Burst Disc Procedure for PFM6 and PFM8 Testers

1. Position the tester block to expose the internal burst disc body as shown in Figure 7.

2. Loosen the burst disc body from the ow meter block.

3. Remove the burst disc body from the ow meter block.

4. Remove the ruptured burst disc from the ow meter block and discard.

5. Clean out the burst disc port. Remove any debris from the sealing surfaces.

6. Rotate the tester to face the burst disc port upwards and drop in a new burst disc. Make sure it lies at on the sealing surface

entrance. Lubricate the O-ring on the burst disc housing and insert it back into the block. Tighten the burst disc housing down to

form the disc against the sealing surface.

7. Using a torque wrench, tighten the burst disc body in the block to 35 foot-pounds (50.8 Nm).

CAUTION

Caution - Do not over torque the burst disc housing. Applying too much torque will damage the burst disc and cause

the disc to rupture prematurely.

Burst Disc Body (1)

Burst Disc (1)

Figure 7: PFM6 and PFM8 Burst Disc

Loading...

Loading...